Pipeliner nr-207xp, Welding positions advantage lincoln, Conformance – Lincoln Electric 2HBG User Manual

Page 14: Typical applications, Deposit composition, Diameters / packaging, Mechanical properties

14

Pipeliner

www.lincolnelectric.com

PIPELINER NR-207XP

AWS: E71T8-K6 Self-Shielded Flux-Cored (FCAW-S) Wire Electrode

For consistently high impact values,

choose 207XP. Optimum perfor-

mance on vertical down, hot, fill and

cap passes on standard cross-country

pipelines and arctic grade pipe.

Recommended for API Pipe Grades

X42 through X70.

WELDING POSITIONS

ADVANTAGE LINCOLN

• Consistently high CVN properties,

even down to -40˚F (-40˚C).

• Virtually eliminates CVN values

below 42 ft•lbf (56 joules).

• Self-shielded, flux-cored. No need

for external gas or flux.

• Produces quality welds in moderate

wind conditions with no tenting.

CONFORMANCE

AWS A5.29-98: E71T8-K6

ASME SFA-5.29: E71T8-K6

• Our quality driven manufacturing

system – certified to ISO 9001 –

and our exceptionally high grade

raw materials mean every coil of

Innershield delivers great arc

characteristics and superior

feedability.

• Manufactured to actual lot control.

Actual certificates of conformance

are available upon request.

TYPICAL APPLICATIONS

• Suggested for use on applications

demanding consistently high tough-

ness.

• Standard cross country pipelines.

• Arctic grade pipe.

1G

2F

4G

2G

5G

➔

3G

➔

%C

%Mn

%P

%S

%Si

%Al

%Ni

%Cr

%Mo

%V

Requirements

AWS E71T8-K6

.15

.50-

.03

.03

.80

1.80

.40-

.20

.15

.05

max.

1.50

max.

max.

max.

max.

1.00

max.

max.

max.

Typical Results

.055

.98

.009

<.003

.07

.80

.61

.04

.03

<.003

DEPOSIT COMPOSITION

- As Required per AWS A5.29

DIAMETERS / PACKAGING

Diameter

14 Lb. (6.3 kg) Coil

in.

(mm)

[ 56 Lb. (25.4 kg)

Master Sealed Pail ]

5/64 (2.0)

ED030925

MECHANICAL PROPERTIES

- As Required per AWS A5.29-98 (Standard AWS Test Plate)

NOTE: Pipeliner elec-

trodes are manufactured

under lot control. A

Certificate of Test showing

actual deposit chemistry

and mechanical properties

per AWS A5.29 is avail-

able on request from the

factory for every lot of

electrode.

(Fax 216-383-8386).

(1)

The strength and elongation properties reported were obtained from a .505" tensile specimen artificially aged at 220°F

(104°C) for 48 hours, as permitted by AWS A5.29-98. A naturally aged tensile specimen may take months to achieve the

specified properties. The time required for the natural aging of weld deposits is dependent upon ambient conditions, weld-

ment geometry, the metallurgical structure of the weld deposit and other factors.

(2)

Standard testing completed to AWS test plate specifications.

Figure 1 below shows results on a simulated pipe joint.

Charpy V-Notch

Yield Strength

Tensile Strength

(1)

Elongation

(1)

ft•lbf (Joules)

(2)

Hardness

psi (MPa)

psi (MPa)

(%)

@ -20°F (-29°C)

@-40°F (-40°C)

Rockwell B

Requirements

58,000 (400)

70,000 - 90,000

20

20 (27)

Not

.

Not

AWS E71T8-K6

min.

(483 - 620)

min.

min.

Required

.

Required

Typical Results

63,000

79,000

30

173 - 251

147

.

NA

(434)

(545)

(234 - 340)

(199)

..

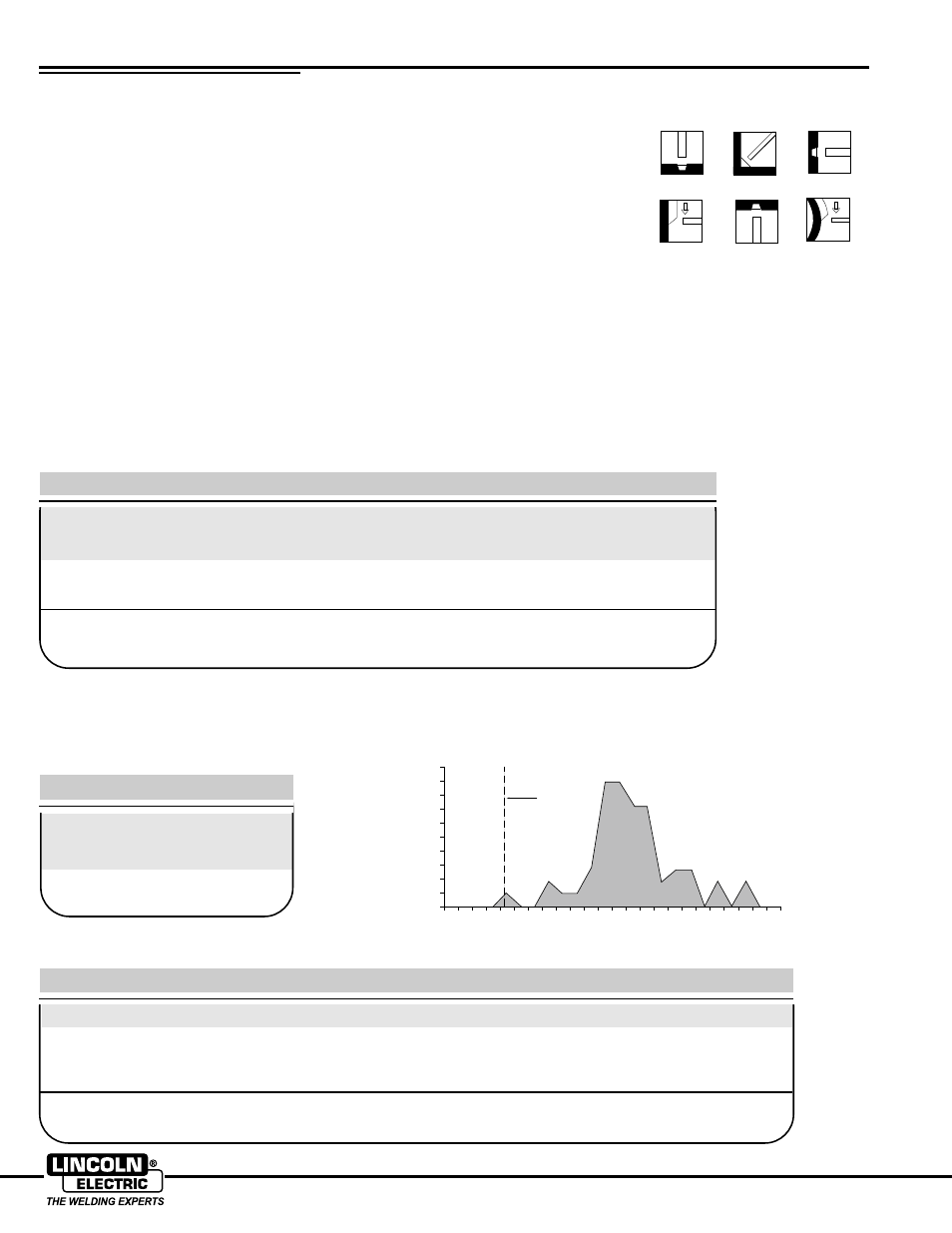

0

40

20

60

80

100

120

140

160

180

200

220

240

0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

CVN (ft-lbs)

%

o

f

T

o

ta

l

S

a

m

p

le

s

Figure 1 – CVN Distribution

E6010 Root Pass on Simulated Pipe Joint

@ -4˚F (-20˚C)

NR-207XP virtually eliminates CVN values below 42 ft•lbf (56 joules).

42 ft•lbf (56 joules)

Typical Operating Procedures – See page 15.