Hydronic piping, Installation & operation manual – Lochinvar KNIGHT 399 - 800 User Manual

Page 39

Installation & Operation Manual

39

6

Hydronic piping

(continued)

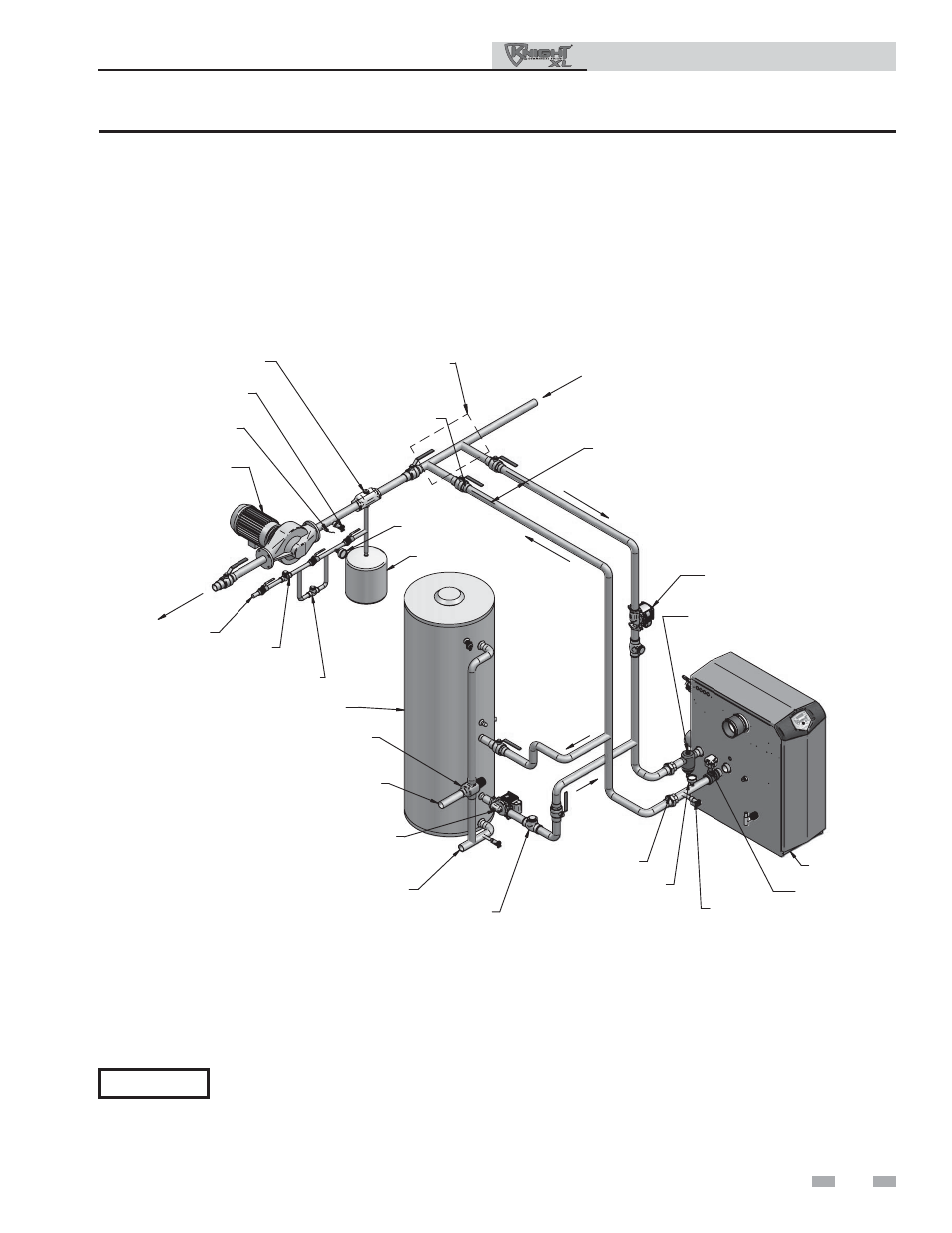

EXPANSION TANK

AIR SEPARATOR

PRESSURE REDUCING

VALVE

BACK FLOW

PREVENTER

BALL VALVE

(TYPICAL)

UNION (TYPICAL)

PRESSURE RELIEF

VALVE

FLOW CHECK

VALVE (TYPICAL)

INDIRECT DHW

TANK

BOILER

TEMPERATURE / PRESSURE

GAUGE

PRESSURE GAUGE

DRAIN

DRAIN POINT

(TYPICAL)

BOILER CIRCULATOR

COLD WATER IN

ANTI-SCALD

MIXING VALVE

SYSTEM SUPPLY SENSOR

(WHEN USED)

SYSTEM CIRCULATOR

TO

SYSTEM

FROM SYSTEM

DOMESTIC

HOT WATER

CIRCULATOR

HOT WATER OUT

MAKE UP WATER

NOT TO EXCEED 4 PIPE DIAMETERS

OR A MAXIMUM OF 12" APART

DIRT SEPARATOR

(RECOMMENDED)

MAY SUBSTITUTE

LOW LOSS HEADER

Figure 6-7 Single Boiler - Primary/Secondary Piping

NOTICE

System flow should always remain higher than the required flow for the boiler(s) when the boiler(s) is in operation to

prevent short cycling and high limit issues.

- KNIGHT XL KBN800 (6 pages)

- SD (2 pages)

- Copper Fin II CF-1261 (1 page)

- EBS-SUB-02 (2 pages)

- Commercial Water Heater (2 pages)

- 999 - 750 (72 pages)

- JR-SUB-07 (2 pages)

- POWER-FIN PB/PF 2001 (4 pages)

- Squire SSS041 (20 pages)

- Knight Heating Boiler 81-286 (48 pages)

- 1302 (2 pages)

- CH/CF/CP 300-750 (4 pages)

- 000 (80 pages)

- Copper-fin CW-360 (1 page)

- CP-5M-4/08 (52 pages)

- 500 (68 pages)

- 000 - 260 (52 pages)

- 000 - 260 (52 pages)

- TNR-I&S-02 (20 pages)

- ARMOR 150 - 800 (36 pages)

- KNIGHT KB-500 (1 page)

- PB 502 thru 1302 (4 pages)

- PB-1302(M9) (1 page)

- MDN 030 (2 pages)

- 495 (52 pages)

- Hot Water Generator (24 pages)

- Heating Boilers KB 400 thru 801 (4 pages)

- SYNO 1.3 (16 pages)

- SQUIRE SIT119 (24 pages)

- Commercial Gas Glass Lined Tanke Type Water Heater CG200 (28 pages)

- COPPER-FIN CB-0745 (1 page)

- 0402-0752 (2 pages)

- 1.3 (56 pages)

- RPV-I&S (16 pages)

- KNIGHT 400 (48 pages)

- KNIGHT 210 (20 pages)

- Power Fin PF-0502 (M9) (2 pages)

- COPPER-FIN II 402 - 2072 (16 pages)

- 752 (16 pages)

- WATER HEATERS (12 pages)

- EFFICIENCY+ E B N 150 (2 pages)

- Sync Condensing Boiler 1.5 (56 pages)

- EB 150 -- 300 (4 pages)

- CW495-2066 (2 pages)

- CREST 2.5 (60 pages)