Lennox International Inc. o23v User Manual

Page 9

Page 9

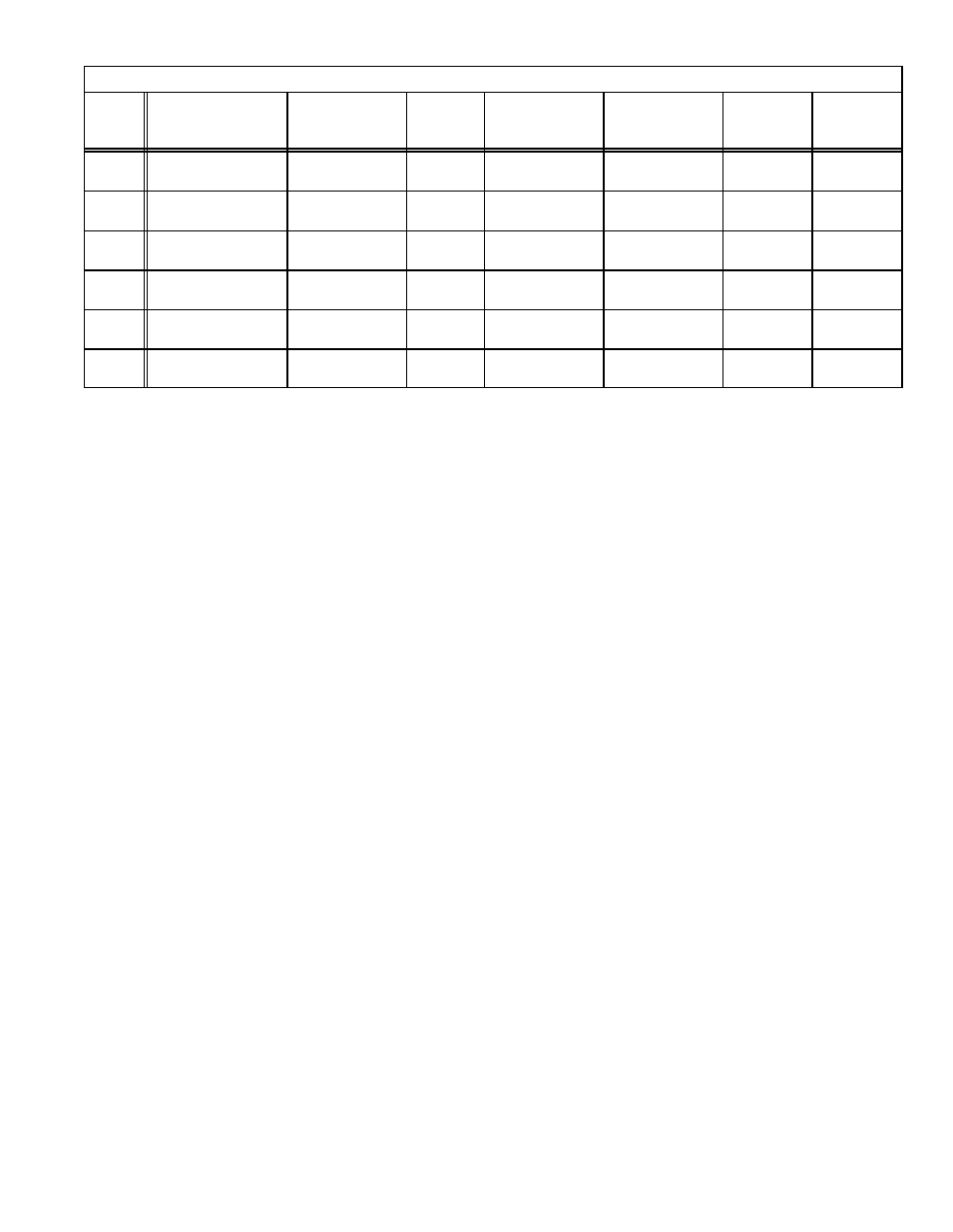

TABLE 6

FURNACE / BURNER SPECIFICATIONS

Unit

Lennox Burner

Part Number

Burner

Model

*Initial

Air Dial

Setting

Output

Nozzle Size

(Delevan)

Pump

Pressure

Head

-70

39M85

AFII 85

3.0

57,000 BTU

(16.7 kW)

0.50 X 80

_A

100 psig

(689.5 kPa)

FB0

-090

39M85

AFII 85

3.5

74,000 BTU

(21.7 kW)

0.50 X 80

_A

100 psig

(689.5 kPa)

FBO

-105

39M86

AFII 85

4.0

84,000 BTU

(24.6 kW)

0.65 X 80

_B

140 psig

965.3 kPa)

FB3

-120

39M86

AFII 85

4.5

105,000 BTU

(30.8 kW)

0.75 X 80

_B

140 psig

965.3 kPa)

FB3

-140

39M87

AFII 150

6.0

112,000 BTU

(32.8 kW)

0.85 X 80

_B

140 psig

965.3 kPa)

FB6

-154

39M87

AFII 150

6.5

125,000 BTU

(36.6 kW)

1.00 X 80

_B

140 psig

965.3 kPa)

FB6

*NOTE: The initial air dial setting is provided to get unit started. The air dial setting MUST be adjusted after start-up to

achieve proper combustion.

F−Burner (Figure 3)

The O23V oil furnace uses the Beckett AFII burner. The oil

burner provides an atomized oil vapor mixed with the correct

proportion of air when it is ignited in the combustion chamber.

Oil burner minimum and maximum ratings are listed on the

unit nameplate. Proper air adjustment for these ratings is

achieved through the air adjustment dial. Set air dial to the ini-

tial air dial setting (see table 6). After start up adjust air dial to

achieve proper combustion. Remember to tighten set screw

on air dial.

The AFII burner is available in six sizes with either a single

or two stage pump. Table 6 identifies the burners used in

Lennox units.

G−Combustion Air Blower / Pump Motor (B6)

The burner is activated by the primary control. A com-

bustion air blower is mounted on the motor shaft. The

motor shaft also connects to the direct drive oil pump

through a coupler. The burner motor turns both the com-

bustion air blower and the oil pump. The motor operates

at 3500 RPM.

Burner motors are overload protected. In the event of

excess motor temperature or current, the overload

opens to de−energize the motor. The overload automat-

ically resets after temperature has returned to normal.

Keep motor clean to prevent starting switch from sticking.

All AFII motors are permanently lubricated. No further oiling is

required.

H− Pump

The O23V units all utilize the Cleancut Fuel Unit manufac-

tured by Beckett. This pump uses a solenoid valve to con-

trol the piston cut−on cut−off operation instead of a cone

valve and diaphram used by other conventional pumps.

The solenoid works with the R7184B Honeywell burner

control to provide cut−on cut−off operation while the burner

motor is at full speed.

At start up the pump shaft is brought to full speed before the

solenoid is energized. At this time low pressure oil

(approximately 20−25 psi) from the gear set circulates

around the pressure regulator piston which is closed and

through the open solenoid valve. The solenoid valve re-

turns the oil to either the cover cavity (one−pipe) or return

line (two−pipe). When the solenoid valve is energized, it

closes (and remains closed while energized) blocking the

return path to the cover cavity and return line creating pres-

sure build up in the piston cavity. The piston opens and reg-

ulates pressure and delivers pressurized oil to the nozzle.

At shutdown the solenoid valve will de−energize and open

before the pump shaft rotation stops. When the solenoid

valve opens the oil by−passes the cover cavity and return

line causing a pressure drop in the piston cavity. The piston

closes blocking oil to the nozzle while the burner motor is

running at full speed.