Troubleshooting: burner fails to start – Lennox International Inc. o23v User Manual

Page 27

Page 27

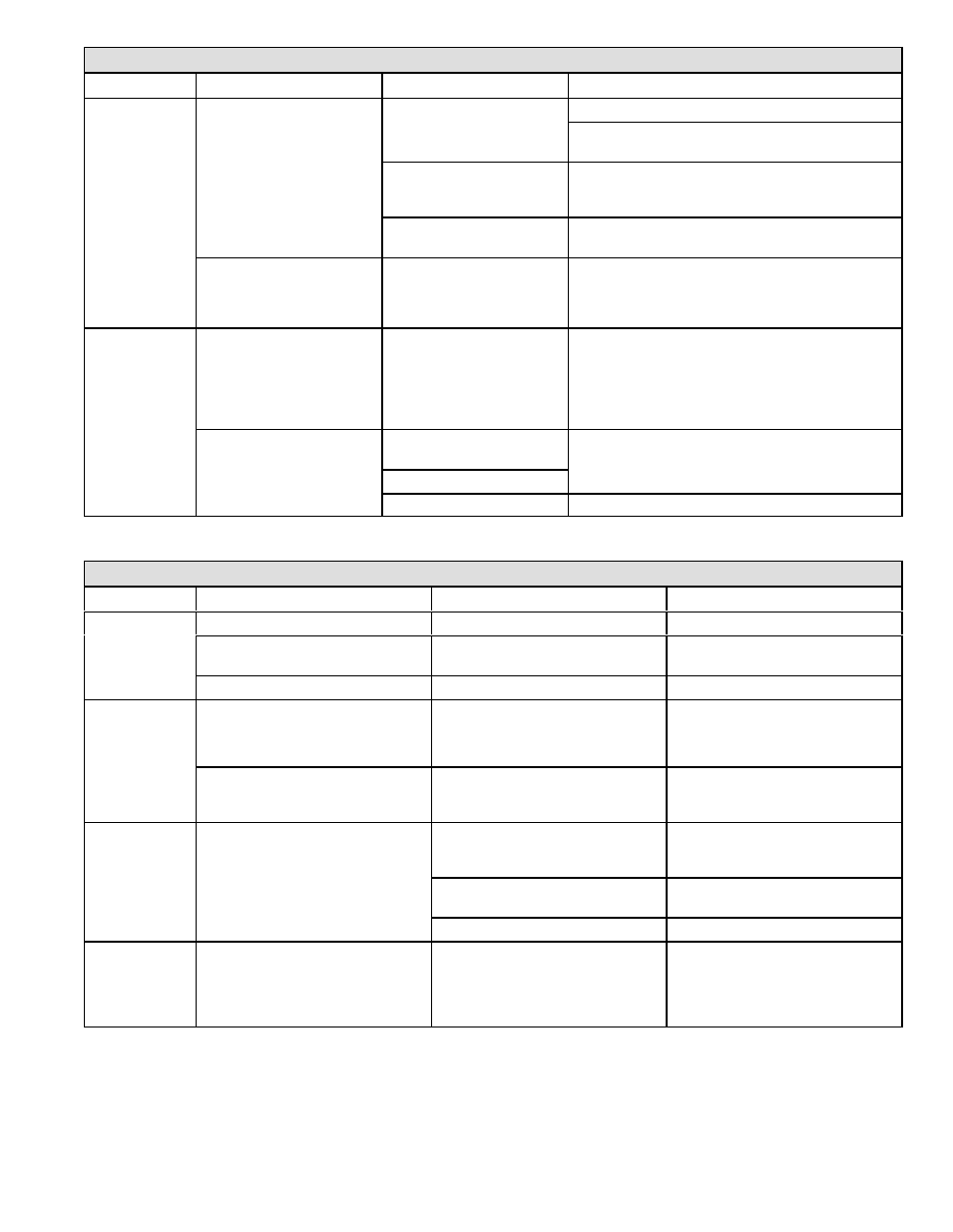

Troubleshooting: Burner fails to start

Source

Correction

Causes

Procedure

Primary Control

Place trouble light between

the black and white leads

Primary or auxiliary control

switch is open

Check adjustment. Set the maximum setting.

the black and white leads.

No light indicates that no

power is going to the

switch is open

Jumper terminals; if burner starts, switch is faulty,

replace control.

power is going to the

control.

Open circuit between

disconnect switch and limit

control

Trace wiring and repair or replace it.

Low line voltage or power

failure

Call the power company.

Place trouble light between

the orange and white leads.

No light indicates faulty

control.

Defective internal control

circuit

Replace the control.

Burner

Place the trouble light

between the black and

white leads to the burner

motor. No light indicates

that no power is getting to

the motor.

Blown fuse

Replace the fuse.

Place trouble light between

the black and white leads to

the blower motor Light

Binding burner blower

wheel

Turn off power and rotate the blower wheel by

hand. If seized, free the wheel or replace the fuel

pump

the blower motor. Light

indicates power to the

Seized fuel pump

pump.

indicates power to the

motor and burner fault.

Defective burner motor

Replace the motor.

Troubleshooting: Burner starts, but no flame is established

Source

Procedure

Causes

Correction

Oil Supply

Check tank gauge or use dip stick.

No oil in tank

Fill tank.

Coat dip stick with litmus paste and

insert into bottom of tank.

Water in oil tank

If water depth exceeds 1 inch,

pump or drain water.

Listen for pump whine.

Tank shut−off valve closed

Open valve.

Oil Filters & Oil

Line

Listen for pump whine.

Oil line filter is plugged

Kinks or restriction in oil line

Plugged fuel pump strainer

Replace filter cartridges.

Repair or replace oil line.

Clean strainer or replace pump.

Open bleed valve or gauge port.

Start the burner. No oil or milky oil

indicates loss or prime.

Air leak in oil supply line

Locate and correct leak.

Tighten all connections.

Oil Pump

Install pressure gauge on pump

and read pressure. −70/90 should

not be less than 100 psi. −105/120,

140/154 should not be less than

Pump is partially or completely

frozen. No pressure and the motor

locks out on overload.

Replace pump.

−140/154 should not be less than

140 psi.

Coupling disengaged or broken − no

pressure

Re−engage or replace coupling.

Fuel pressure too low

Adjust psi.

Nozzle

Disconnect ignition leads. Observe

the oil spray (gun assembly must

be removed from unit). Inspect the

nozzle for plugged orifice or carbon

build−up around orifice.

Nozzle orifice plugged

Nozzle strainer plugged

Poor or off center spray

Replace nozzle with the same size,

spray angle, and spray type.