Kodak EKTACOLOR PRIME LORR CIS-267E User Manual

Page 3

Using KODAK Chemicals with KONICA 808 and Related Minilabs ● KODAK Publication No. CIS-267E

Developer Fresh Tank Solution

To ensure good performance, take special care in mixing the

developer tank solution. You should mix the developer

replenisher in a separate mixing vessel from the one used for

bleach-fix.

Preparing Developer Tank Solution from KODAK

EKTACOLOR PRIME SP Developer Replenisher

LORR, To prepare 1L.

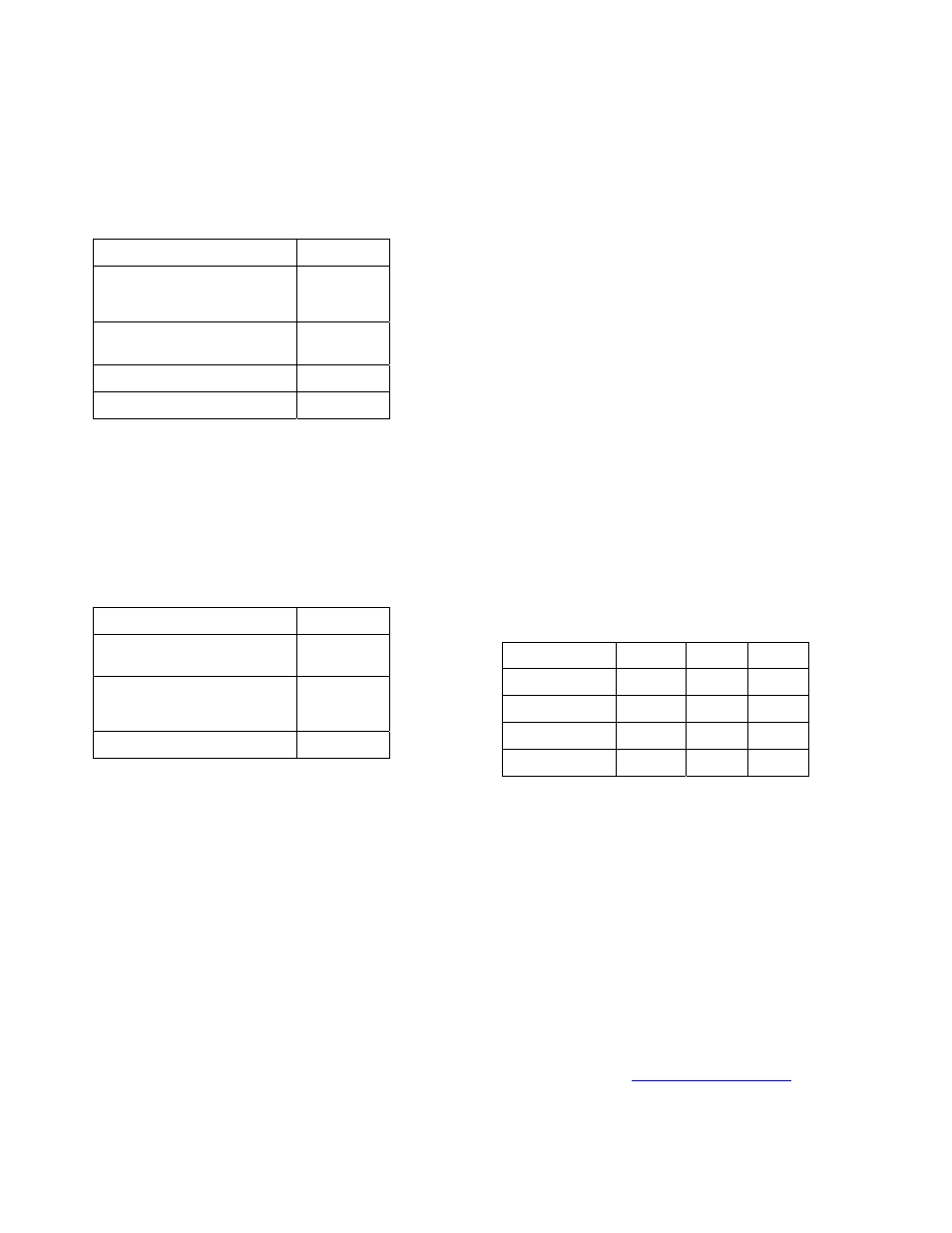

Table 3

Volume

EKTACOLOR PRIME SP

Developer LORR, mixed

Replenisher*

670ml

EKTACOLOR RA Developer

Starter (CAT No 5278957),

24mL

Water 306mL

Total volume

1.0 L

* Mixed as directed on the product label

Bleach-Fix Fresh Tank Solution

Be very careful to avoid contamination of the developer

with bleach-fix.

Preparing Bleach-Fix Tank Solution from KODAK

EKTACOLOR PRIME SP Bleach-Fix Replenisher

LORR

Table 4

Volume

EKTACOLOR PRIME SP Bleach-

Fix LORR, mixed Replenisher*

950ml

EKTACOLOR PRIME SP

Bleach-Fix Starter (CAT No.

5288139)

50mL

Total volume

1.0 L

* Mixed as directed on the product label

Stabilizer Fresh Tank Solution

Mix the working tank solution in each of the stabilizer

tanks.

To prepare one litre of stabilizer tank solution, mix

EKTACOLOR PRIME Stabilizer and Replenisher LORR

(as directed on the product label), no further dilution is

required.

Reinstalling the Racks and Bringing the Tank

Solutions to Temperature

You should allow some space when filling the tanks, to

allow for the volume of the racks. When you reinstall the

racks in the tanks, the racks will displace more solution

volume to fill the tanks.

Install the racks by slowly lowering them into the

tanks. When you have reinstalled all the racks and have

verified that all the tanks are filled with solution, turn on

the recirculation and heater system and bring the solutions

up to operating temperature.

USING CONTROL STRIPS TO MONITOR THE

PROCESS

Use KODAK Control Strips, Process RA-4 (box of 50,

CAT No. 8282170), to monitor process performance. For

instructions on processing control strips, see the operator’s

manual for the KONICA Minilab.

For information on the

use and diagnostic features of the control strips, see

KODAK Publication No. Z-130, Using KODAK

EKTACOLOR Chemicals, Section 7, “Process Monitoring

and Troubleshooting with KODAK Control Strips, Process

RA-4.” KODAK Publications are described and available on

the Kodak website at

www.Kodak.com/go/photochemicals.

To calculate control-strip aim values for process

monitoring, you will need to apply process adjustment

factors. Use the adjustment factors in addition to the

correction factors that are supplied with the control strips.

After reading the densities of the supplied reference

strip on your densitometer, first apply the “Prime”

correction factors packaged with the reference strip. Then

add the values from the following table. The corrected

density values are the aim values for your batch of control

strips. You will need to apply the adjustment factors each

time you switch to a new batch of control strips.

Table 5. Process Adjustment Factors

Measurement R G B

Black (BP)

+0.07

+0.01

-0.05

High (HD)

+0.01

+0.07

-0.06

Low (LD)

-0.04

+0.05

-0.07

D-min

+0.01 +0.01 +0.01

SILVER RECOVERY

When an effluent tank is full, the processor alerts you to

drain the tank.

Typically, silver concentration in the bleach-fix effluent

tank will be 4 to 8 g/L; silver concentration in the stabilizer

effluent tank will be 0.2 to 0.6 g/L.

You can effectively use common silver-recovery

methods with the combined effluents from both effluent

tanks. If your lab has other processors, you can combine the

effluent from the KONICA Minilab with the other effluent

solutions and use your current silver-recovery methods.

Publications on silver management that include

recommendations and descriptions of silver-recovery

options are available in the Silver Management section of

the KODAK Product Safety, Recycling & Disposal Center,

under “Chemicals” at

www.Kodak.com/go/KES

.