Sears 183.91579 User Manual

Page 15

14

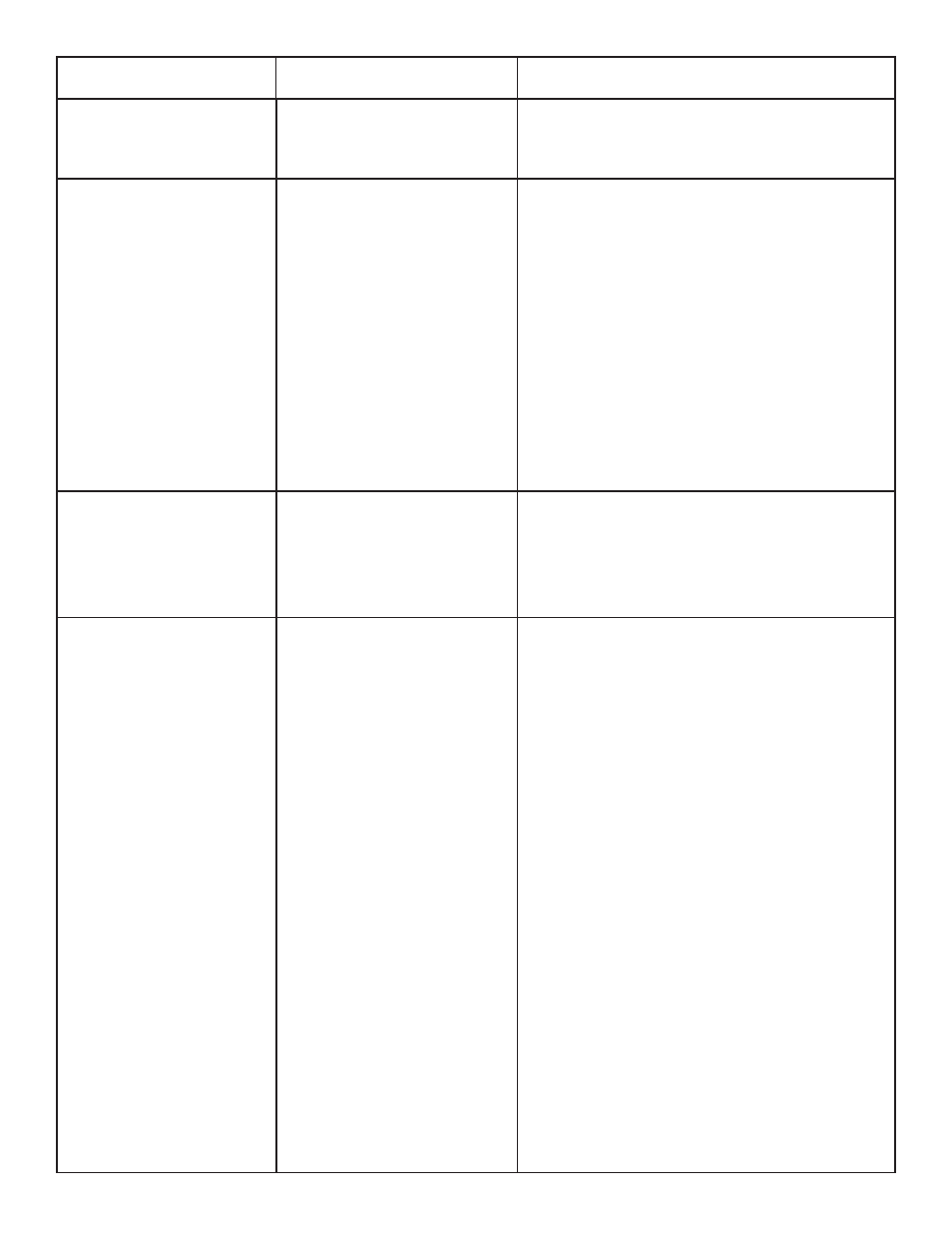

PROBLEM

CAUSE

CORRECTION

Loose Foam.

Large soap-like bubbles that

settle quickly.

Off-Taste Beer.

Often bitter and bitey;

sometimes completely lack-

ing in flavor and zest. May

also have an oily or foul

odor, which carries an

unpleasant taste.

Sour Beer.

Beer tastes and smells

extremely yeasty or moldy.

Wild Beer.

Beer that is either all foam,

or too much foam and not

enough liquid.

• This is generally the same as

the Flat Beer condition.

• Improper cleaning of the tap.

• Contaminated air line.

• Improper type of beer tube

• Improper transporting of beer

kegs. Beer that is delivered

on an open truck during high

summer temperatures may

start a secondary fermentation

process.

• Improper drawing of beer into

the glass.

• Yeast growth or other obstruc-

tions in the faucet, which is

usually caused by a non-refrig-

erated faucet. Worn faucet

parts and worn faucet washers.

• The beer was stored in an area

that is not cold enough and

has thus become warm.

• Too much air pressure.

• Excessive amounts of CO

2

.

• See the Flat Beer causes above.

• Brush and clean the tap properly. It should be

scoured using a detergent, then rinsed clean.

• Beer tube should be examined. If contaminated, it

should be replaced.

• A rubber hose will absorb and retain odors. Try

using a plastic tube instead.

*General Recommendations for Off-Taste Beer:

Beer lines should be flushed after each keg is

emptied. Maintain fresh, clean, sanitary conditions

around the dispenser. Smoke, cooking odors and

disinfectants will harm the taste and flavor of beer.

These conditions, as described, may come from an

air source or from actual contact with the glass when

drawing beer.

• If possible, have beer kegs delivered in a closed,

refrigerated truck. If an open truck is used, cover

beer kegs with tarpaulin for protection against

summer heat and warm air.

• Open the faucet quickly and completely.

• Proper foam should be a tight, creamy head, and

the collar on the average glass should be 3/4" to 1"

high.

• Check for, and replace any kinked, dented, or

twisted lines from the barrel to the faucet.

• Examine for frayed coupling washers behind the

faucet that may cause an obstruction.

• Keep kegs of beer refrigerated at all times at

38˚F-40°F all year round!

• First, check the source of pressure to make sure it is

working. Then adjust the pressure to suit a properly

balanced system. The correct beer flow should fill a

10oz. glass in 4 seconds at the proper temperature.

• Adjust the CO

2

pressure to as low as possible.

However, the applied pressure must remain slightly

higher than the internal pressure of the beer. No

more than 18 lbs. should be applied. The proper

amount should be between 10-12psi/lbs.

• The colder the beer and the higher the applied

CO

2

pressure, the more rapid the absorption of

CO

2

by the beer. This over-carbonates the beer,

causing Wild Beer.

• Check the pressure regulators periodically to ensure

that the operating pressures remain constant.