Operation – Southbend SB1044 User Manual

Page 3

Mfg. Since 6/10

Model SB1044

-3-

I N S T R U C T I O N S

Operation

Only use high quality water-soluble cutting

fluid in this system. Never attempt to pump

straight cutting oils or kerosene. If you do, the

higher viscosity of the oil will overload the motor,

causing damage, or flammable liquids may

ignite.

Following the cutting fluid manufacturer’s

guidelines, check and maintain the specific

gravity of the cutting fluid to its required level.

Change the fluid when it becomes overly dirty,

rancid, or contaminated.

To use the cutting fluid system:

1. Make sure the cutting fluid is properly

serviced and the tank is filled.

2. Put on the necessary personal protection

equipment.

3. Position the cutting fluid nozzle for your

operation.

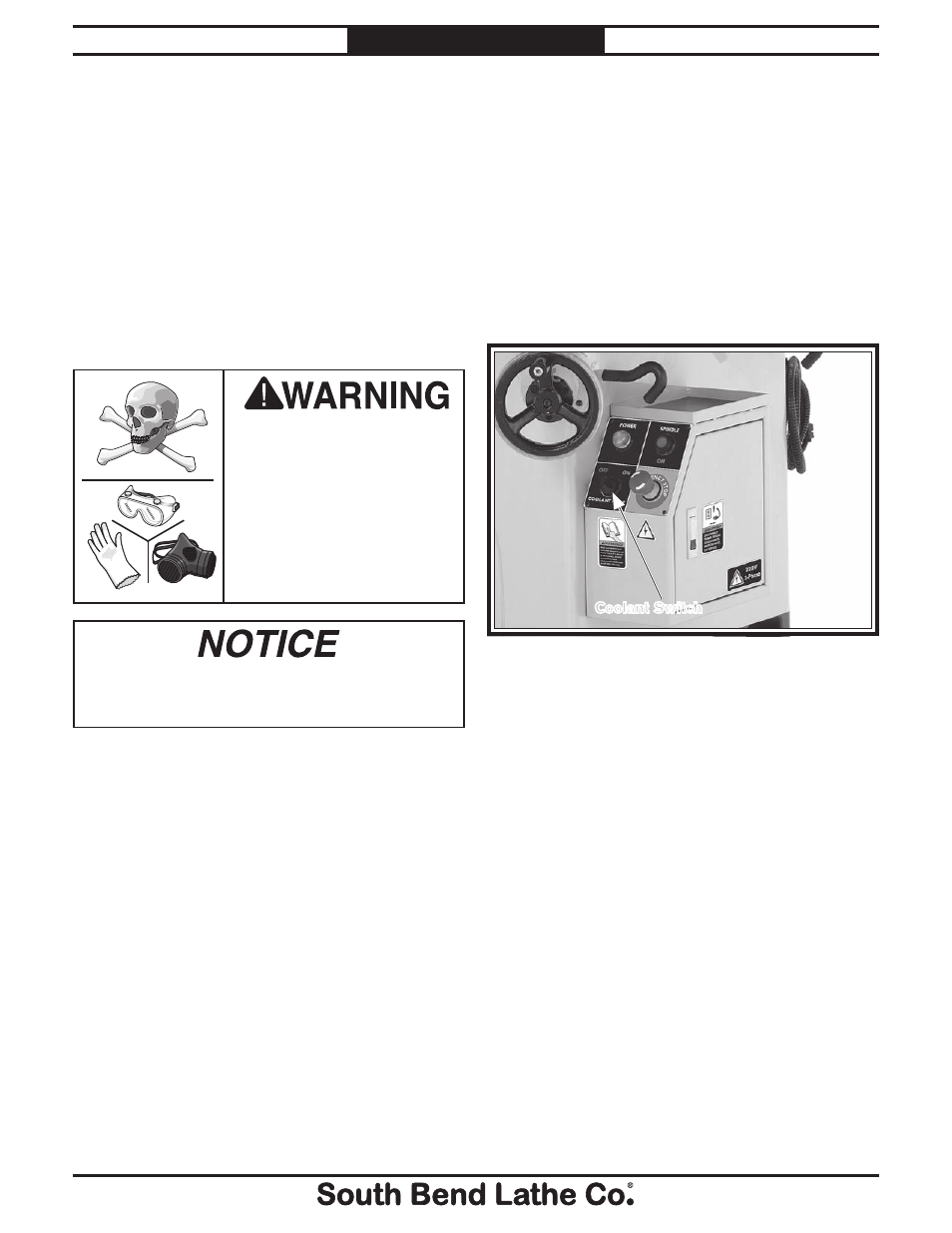

4. Use the control panel coolant switch to turn

the cutting fluid pump ON.

Figure 3. SB1029 control panel.

5. Adjust the flow of cutting fluid for the type of

flooding required.

Note: Promptly clean any splashed cutting fluid

from the floor to avoid a slipping hazard.

Coolant Switch

BIOLOGICAL & POISON

HAZARD!

Use the correct personal

protection equipment

when handling cutting

fluid. Follow federal, state,

and fluid manufacturer

requirements for proper

disposal.

Running the pump without adequate fluid in

the tank may permanently damage it. This

damage is not covered by warranty.