Installation – Southbend SB1044 User Manual

Page 2

-2-

Mfg. Since 6/10

Model SB1044

I N S T R U C T I O N S

Installation

During the installation process of your cutting

fluid kit, you'll need the following items:

For Power Connection

• A power source that meets the minimum

circuit requirements for this machine.

• A qualified electrician to ensure a safe and

code-compliant connection to the power

source.

For Assembly

• Phillips Screwdriver #2

• Cotton Rags and Silicone Sealant

• Hex Wrenches 3, 5mm

• Safety Goggles

• Wrench 27mm

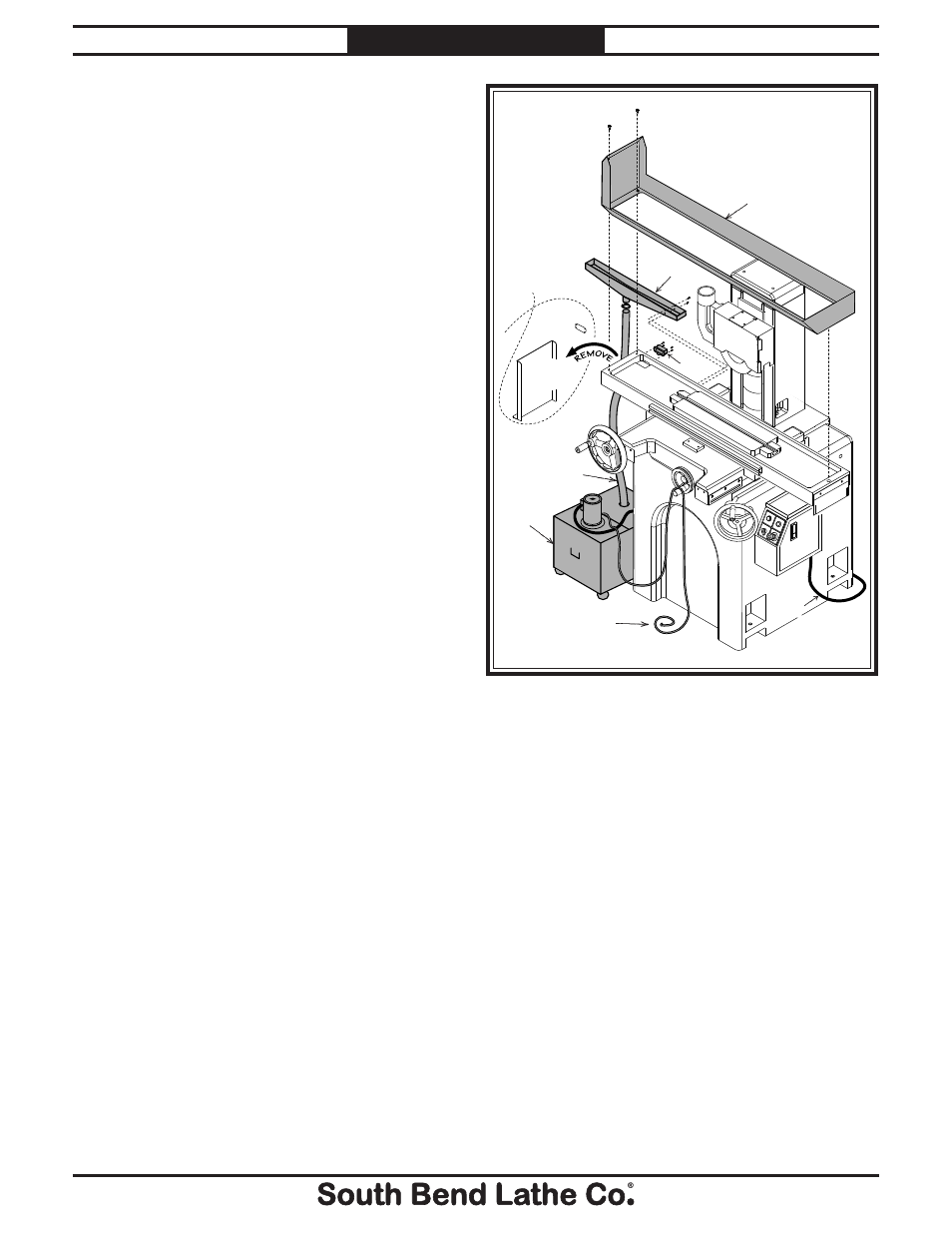

Spash

Port

Tank

Trough

Power

Cord

Guard

Shield

Drain

Hose

Connect Delivery

Hose to Desired

Cutting Fluid Nozzle

SB1029

Chip

Cover

Drain

Figure 2. Cutting fluid system installation.

6. Apply silicone sealant to the mounting flange

of the port shown in Figure 2.

7. Using the fasteners from the machine in

Step 5, install the port, splash guard, and

the trough to the machine, as shown in

Figure 2.

8. Insert one end of the drain hose into the

tank, and fasten the other end to the trough

using the hose clamp.

9. Route the delivery hose out of the way and

fasten the delivery hose to your desired

cutting fluid nozzle with the hose clamp.

10. Fill the tank with premixed water soluble

cutting fluid.

To install the cutting fluid kit:

1. DISCONNECT THE SURFACE GRINDER

FROM POWER.

2. Fasten the four swivel caster wheels to the

tank, and make sure the drain plug is tight.

Tip: Place one or more strong magnets at the

bottom of the tank to collect fine metal

particles from the cutting fluid.

3. Route the pump power cord around the

backside of the surface grinder, or fasten it

up and away from the floor.

4. Connect the SB1044 power cord to the

surface grinder as outlined on the Model

SB1029 Pump Connection Wiring

Diagram on Page 7.

If the surface grinder uses a 440V power

supply, the pump motor must be rewired as

shown in the OPTIONAL 440V 3-PHASE

CONNECTION diagram on Page 7.

5. Remove the existing chip shield and drain

cover from the table, as shown in Figure 2.

Retain the fasteners to install the SB1044

splash guard and port.

Note: For shipping purposes, the front and rear

splash panels are fastened together with four

wing nuts on the rear splash guard wall.