Figure 46, Figure 47, Step 6. connecting gas line – Superior DT-400CMP User Manual

Page 21: Figure 48, Gas connection

21

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

FBK-250 Blower Kit (See

Figure 46)

An electrical outlet box is provided for the instal-

lation of the FBK-250 forced air blower kit.

Electrical power must be provided to this box to

operate these blowers. Install the blower kit

according to the installation instructions pro-

vided with the kit.

1. Route a 3-wire, 120Vac 60Hz 1ph power line

to the lower right rear corner of the appliance.

2. Remove the outlet box by removing two

screws.

3. Connect the black supply wire to both of the

outlet box' pigtail leads and the white supply

wire to the common terminal of the outlet box

as shown in

Figure 46.

4. Connect the ground supply wire to the

outlet's green ground screw.

5. Reinstall the outlet box.

6. Insert the kit-provided module plug into the

top outlet.

(The bottom outlet is unused on millivolt

units, while the burner control circuit plugs

into the bottom outlet on electronic units.)

7. Insert the blower plug into the module's

receptacle.

Figure 46

1. If any of the original wire as supplied must be replaced,

1.

it must be replaced with

Type AWM 105

°

C – 18 GA. wire.

2. 120V, 60Hz – Less than 3 amps.

BK

Transf.

120 V.

24 V

Factory Wired

Field Wired

BL

Electronic Wiring Diagram (Honeywell)

Showing the Blower Wiring for the Optional

FBK-250 Kits

R

WH

BL

OPT

BLOWER

G

W

120

VAC.

BK

W

Gas Valve

B

R

IGNITER

PILOT

ASSEMBLY

BK

G

Outlet Box Green

Ground Screw

Hot side of Outlet

Schematic Representation Only

*ON/OFF Switch (Integral

with Gas Valve)

White Wire

To Opposite

Side

Optional FBK-250

Module

*Leave the ON/OFF switch, which is integral

with the gas valve, in the ON position.

G

OPTIONAL APPLIANCE-MOUNTED ON/OFF SWITCH

OR OPTIONAL WALL SWITCH

OR OPTIONAL THERMOSTAT

OR OPTIONAL REMOTE RECEIVER

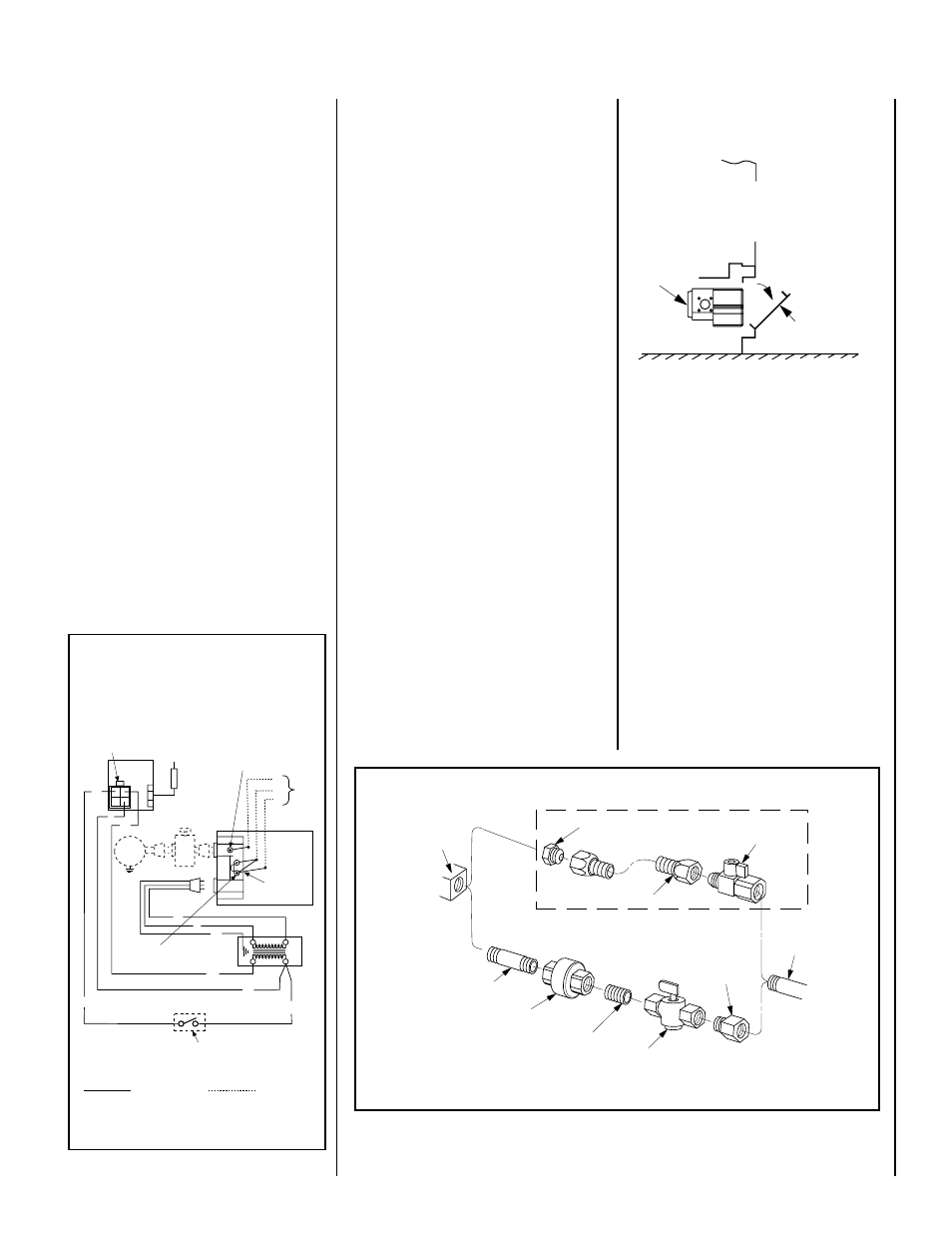

Gas

Stub

¹ ₂" x ³ ₈" Flare

Shut-Off Valve

³ ₈" Flex Tubing

³ ₈" NPT x ³ ₈

Flare Fitting

³ ₈" Nipple

³ ₈" Union

³ ₈" Close Nipple

³ ₈" Shut-Off Valve

¹ ₂ x ³ ₈ "

Reducer

Gas

Valve

Optional Gas Flex Line Connector

Figure 47 -

GAS CONNECTION

Step 6. CONNECTING GAS LINE

Make gas line connections. All codes re-

quire a shut-off valve mounted in the supply

line.

Figure 47 illustrates two methods for

connecting the gas supply. The flex-line

method is acceptable in the U.S., however,

Canadian requirements vary depending on

locality. Installation must be in compliance

with local codes.

These appliances can be equipped with a gas

flex line for use (where permitted) in connect-

ing the unit to the gas line. The gas flex line

(not provided) is to aid in attaching the direct

vent appliance to the gas supply. The gas flex

line can only be used where local codes per-

mit. See

Figure 47 for flex line description.

The flex line is rated for both natural and

propane gas. The optional gas flex line is

equipped with a manual shut off valve.

Open the control compartment access panel

(Figure 48) by actuating the spring-loaded

magnetic catches securing the panel, gently

depressing the outer top corners of the panel

until the catches "pop" the panel free, allowing

it to swing out and down to open.

The millivolt control valve has a

³⁄₈"

(10 mm) NPT thread inlet port.

Secure all joints tightly using appropriate

tools and sealing compounds (ensure pro-

pane resistant compounds are used in pro-

pane applications).

Turn on gas supply and test for gas leaks using

a soapy water solution. Never use an open

flame to check for leaks.

Figure 48

A. Mix a 50% dish soap, 50% water solution.

B. Light the appliance (refer to the lighting

instructions provided in the Homeowner's Care

and Operation Instructions).

C. Brush all joints and connections with the

soapy water solution to check for leaks. If

bubbles are formed, or gas odor is detected,

turn the gas control knob to the “OFF” position.

Either tighten or refasten the leaking connec-

tion and retest as described above.

D. When the gas lines are tested and leak free,

observe the individual tongues of flame on the

burner. Make sure all ports are open and pro-

ducing flame evenly across the burner. If any

ports are blocked, or partially blocked, clean

out the ports.

Opening Control Compartment Door

Control

Valve

Lower Control

Compartment

Door

Open the lower panel or louver assembly by

gently depressing the outer top corners of the

panel until the catches “pop” the panel free,

allowing it to swing out and down to open.