Superior DT-400CMP User Manual

Page 11

11

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

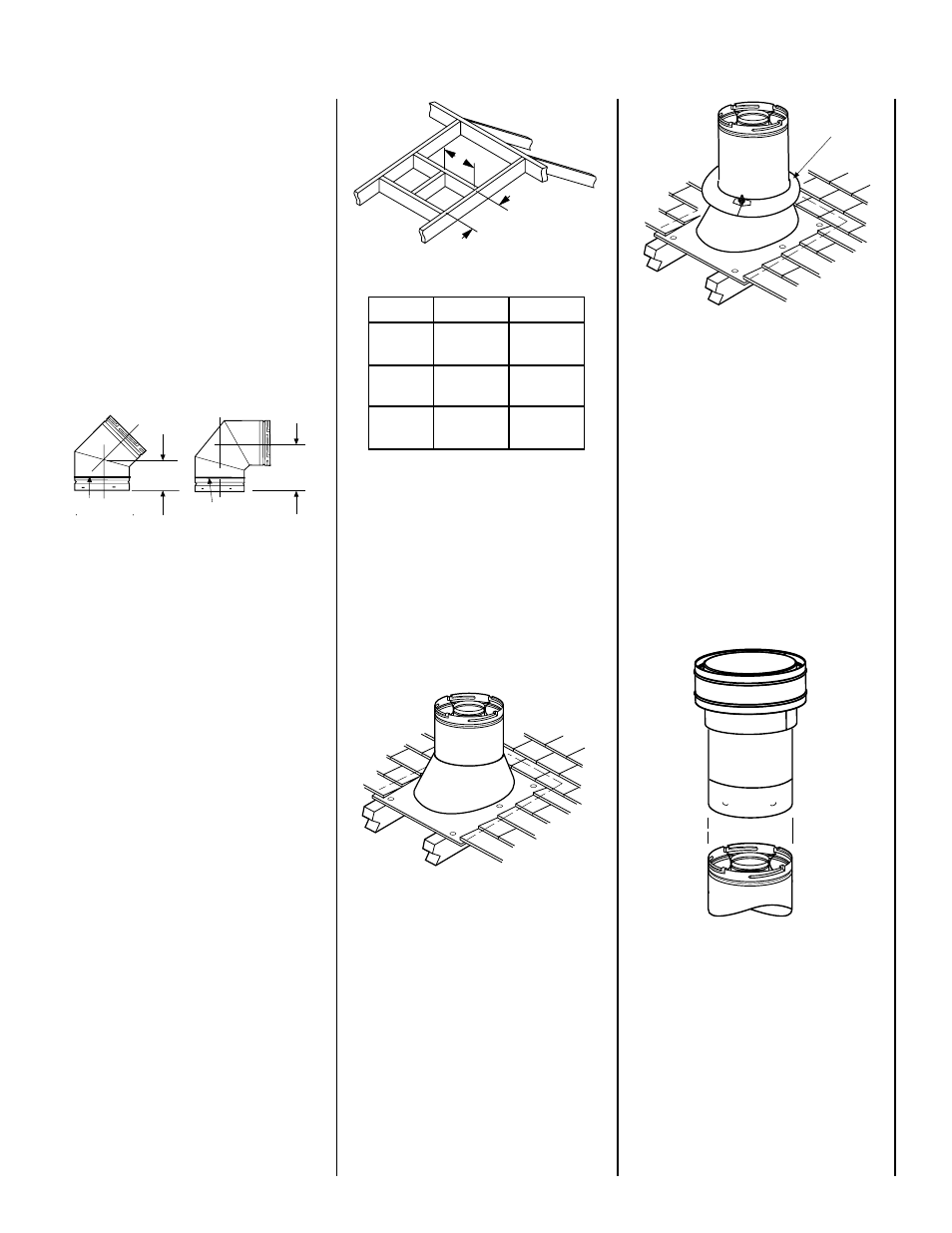

Framing Dimensions for Roof

Pitch

C

D

0/12

10

¹⁄₂ in.

10

¹⁄₂ in.

(267 mm)

(267 mm)

6/12

10

¹⁄₂ in.

12 in.

(267 mm)

(305 mm)

12/12

10

¹⁄₂ in.

17

³⁄₄ in.

(267 mm)

(451 mm)

SV4.5E90

(90

°

Elbow)

8

¹⁄₈"

(206 mm)

Swivel Joint

(360

°

swivel)

4

¹³⁄₁₆"

(122 mm)

SV4.5E45

(45

°

Elbow)

Swivel Joint

(360

°

swivel)

C

D

Storm

Collar

Figure 19

Figure 20

Figure 22

Figure 21

Figure 18

K. Install the vertical termination - The final

step involves installation of the SV4.5CGV-1

Vertical Termination. Extend the vent sections to

the height as shown in the "Vertical vent termina-

tion section" on page 5. The SV4.5CGV-1 Verti-

cal Termination (

Figure 22 ) installs in the exact

same fashion as any other Secure Vent section.

Align the termination over the end of the previ-

ously installed section, adjusting the radial align-

ment until the four locking dimples of the termi-

nation are aligned with the inlets of the four

incline channels of the last vent section. Push the

termination down until it fully engages, then twist

the termination clockwise running the dimples

down and along the incline channels until they

seat at the end of the channels.

I. Install the roof flashing - Extend the vent

sections through the roof structure. Install the

roof flashing over the vent section and posi-

tion such that the vent column rises vertically

(use carpenters level) (

Figure 20 ). Nail along

perimeter to secure flashing or adjust roofing

to overlap the flashing edges at top and sides

only and trim where necessary. Seal the top

and both sides of the flashing with waterproof

caulking.

If the vent system extends more than 5' (1.5 m)

above the roof flashing, stabilizers may be

necessary. Additional screws may be used at

section joints for added stability. Guide wires

may be attached to the joint for additional

support on multiple joint configurations.

G. Continue installation of horizontal/inclined

sections - Continue with the installation of the

straight vent sections in horizontal/inclined run

as described in Step C. Install support straps

every 5' (1.52 m) along horizontal/inclined vent

runs using conventional plumber’s tape.

It is

very important that the horizontal/inclined

run be maintained in a straight (no dips) and

recommended to be in a slightly elevated

plane, in a direction away from the fireplace

of

¹⁄₄" rise per foot (20 mm per meter) which is

ideal, though rise per foot run ratios that are

smaller are acceptable all the way down to at or

near level. Use a carpenter’s level to measure

from a constant surface and adjust the support

straps as necessary.

It is important to maintain the required clear-

ances to combustibles: 1" (25 mm) at all sides

for all vertical runs; and 3" (76 mm) at the top,

1" (25 mm) at sides, and 1" (25 mm) at the

bottom for all horizontal/inclined runs.

H. Frame roof opening - Identify location for

vent at the roof. Cut and/or frame opening per

Roof Framing Chart and

Figure 19.

J. Install the storm collar - Install the storm

collar, supplied with the flashing, over the vent/

flashing joint. See

Figure 21. Loosen the storm

collar screw. Slide collar down until it meets the

top of the flashing. Tighten the adjusting screw.

Apply non-combustible caulking or mastic

around the circumference of the joint to pro-

vide a water tight seal.

Loop the tape around the vent, securing the

ends of the tape to the framing. If desired,

sheet metal screws #6 x

¹⁄₂" length may be

used to secure the support straps to the vent

pipe. Refer to

Figure 17.

F. Change vent direction to horizontal/inclined

run - At transition from or to a horizontal/

inclined run, install the SV4.5E45 and SV4.5E90

elbows in the same manner as the straight vent

sections. The elbows feature a twist section to

allow them to be routed about the center axis of

their initial collar section to align with the re-

quired direction of the next vent run element.

Twist elbow sections in a clockwise direction

only so as to avoid the possibility of unlocking

any of the previously connected vent sec-

tions. See

Figure 18.