Southbend SB1269 User Manual

Page 9

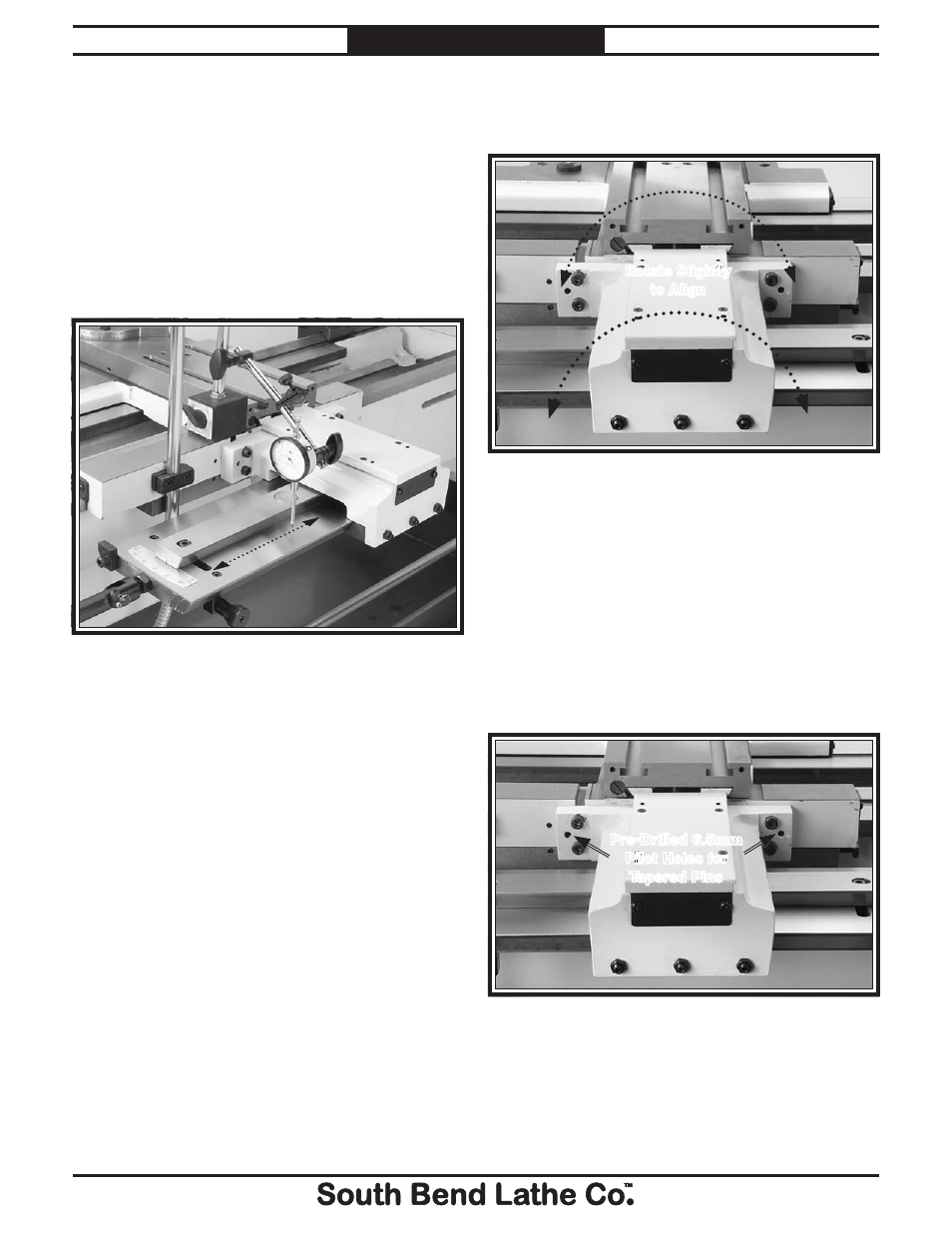

35. Loosen the four mounting cap screws and

rotate the taper attachment left or right to

correct the alignment (see Figure 21).

Figure 22. Roll pin installation.

Pre-Drilled 6.5mm

Pilot Holes for

Tapered Pins

36. Retighten the taper attachment cap screws,

and double check your parallelism.

37. Using the existing pilot holes in the taper

attachment housing as guides (see Figure

22), drill out both holes with a

19

⁄

64

" drill bit,

and ream both holes with an industrial size

#6 spiral pin reamer deep enough so the

tapered pins fit flush. If you need to remove

the tapered pins for any reason, the internal

pin threads are a metric M6-1.

38. Position and tap-in the tapered pins, so they

will permanently lock the taper attachment

in the current alignment position.

39. Reinstall the lathe splash guard.

33. Setup a knob indicator as shown in Figure

20, so the knob indicator point is against the

top of the dovetailed table.

34. Move the carriage to the other end of the

way, read the knob indicator, and note the

amount of total misalignment in parallelism

between the path of the carriage and the

path of the taper attachment.

— If the knob indicator readings show a tilt

of 0.025" or less between the two extreme

positions of the taper attachment, then the

alignment is acceptable. Go to go to Step 37.

— If the parallelism is greater than 0.025",

proceed to Step 35.

30. Using a 3mm hex wrench, tighten the

cam set screws and the clevis jam nut (see

Figure 16) when finished.

31. Using 8mm and 6mm hex wrenches, tighten

the deadman clamp and the arm clamp cap

screws, as shown in Figure 18.

32. Move the carriage so the taper attachment

stops completely at the forward-most

position, as shown Figure 20.

Figure 20. Taper attachment alignment.

Figure 21. Parallelism correction.

Rotate Slightly

to Align

For Product Mfg. Since 1/10

Model SB1269

-9-

P R E P A R A T I O N