Southbend SB1269 User Manual

Page 8

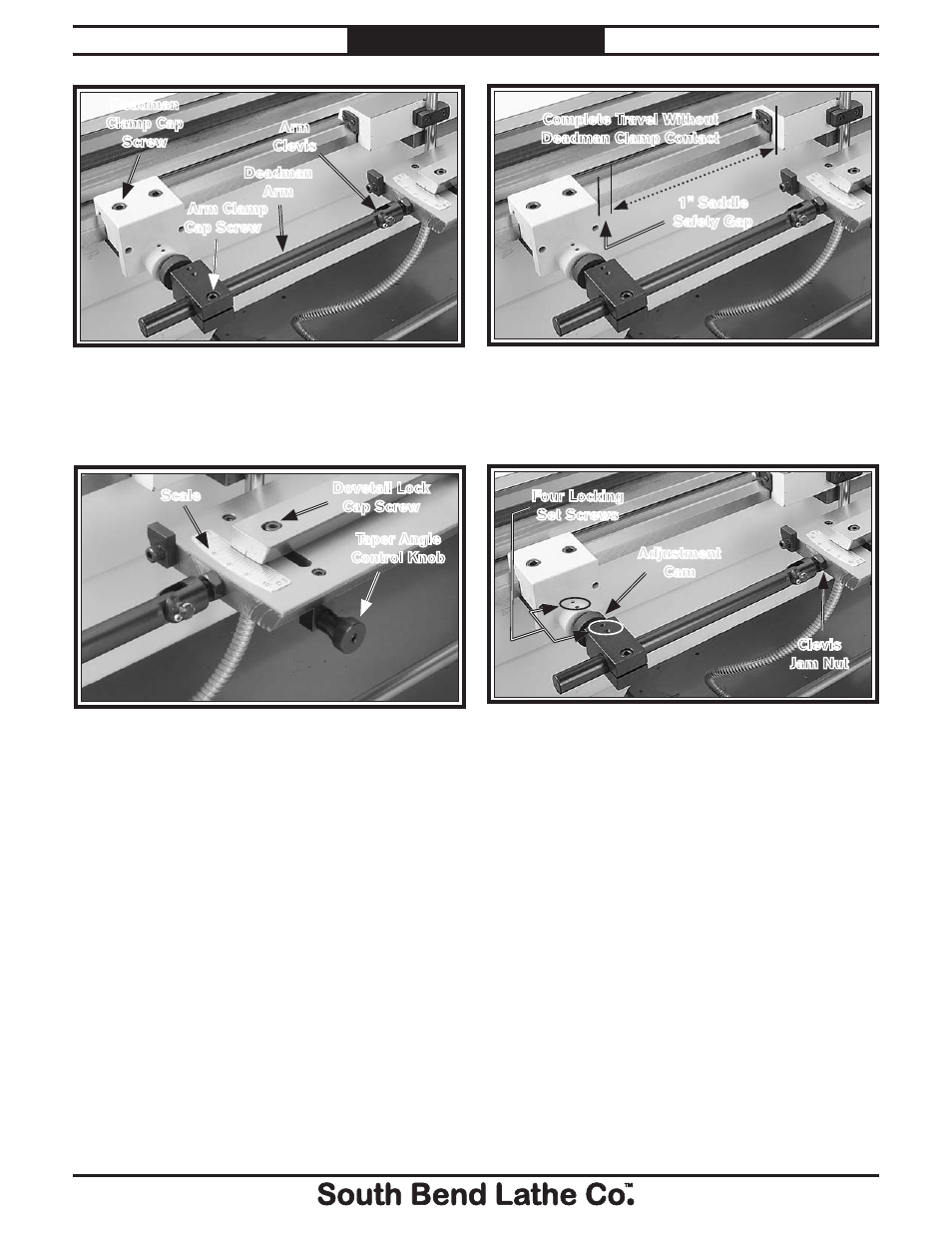

Figure 16. Deadman and arm installation.

Deadman

Clamp Cap

Screw

Deadman

Arm

Arm

Clevis

Arm Clamp

Cap Screw

29. Rotate, push in, or pull out the adjustment

cam to adjust the deadman arm so it is as

parallel as possible with the lathe bed in

both the vertical and horizontal plane.

Note: You may have to rotate the deadman arm

so the arm clevis allows the arm to be tilted

in a particular direction.

— To tilt the arm in the vertical plane, rotate

the knurled adjustment cam.

— To tilt the arm in the horizontal plane, slide

the adjustment cam in or out of the deadman

housings.

Figure 18. Saddle gap.

Complete Travel Without

Deadman Clamp Contact

1" Saddle

Safety Gap

28. Using a 3mm hex wrench, loosen the four

locking set screws (Figure 19) that lock the

adjustment cam in position.

24. Using a 6mm hex wrench, loosen the

dovetail lock cap screw at each end of the

taper attachment, as shown in Figure 17.

Figure 19. Deadman arm alignment.

Four Locking

Set Screws

Adjustment

Cam

Clevis

Jam Nut

Figure 17. Taper angle adjustment.

Dovetail Lock

Cap Screw

Taper Angle

Control Knob

Scale

25. Turn the taper angle control knob (Figure

17), so the taper attachment points to zero

degrees as shown on the scale.

26. Re-tighten both dovetail lock cap screws.

27. Slide the deadman clamp along the lathe

way to a position where the saddle will not

contact the clamp when cutting tapers.

There should be approximately 1" of safety

clearance or "saddle safety gap," as shown

in Figure 18. You must double check this

clearance to prevent a deadman clamp

carriage crash.

-8-

For Product Mfg. Since 1/10

Model SB1269

P R E P A R A T I O N