Slant/Fin BOILERS User Manual

Page 10

10

LIBERTY II

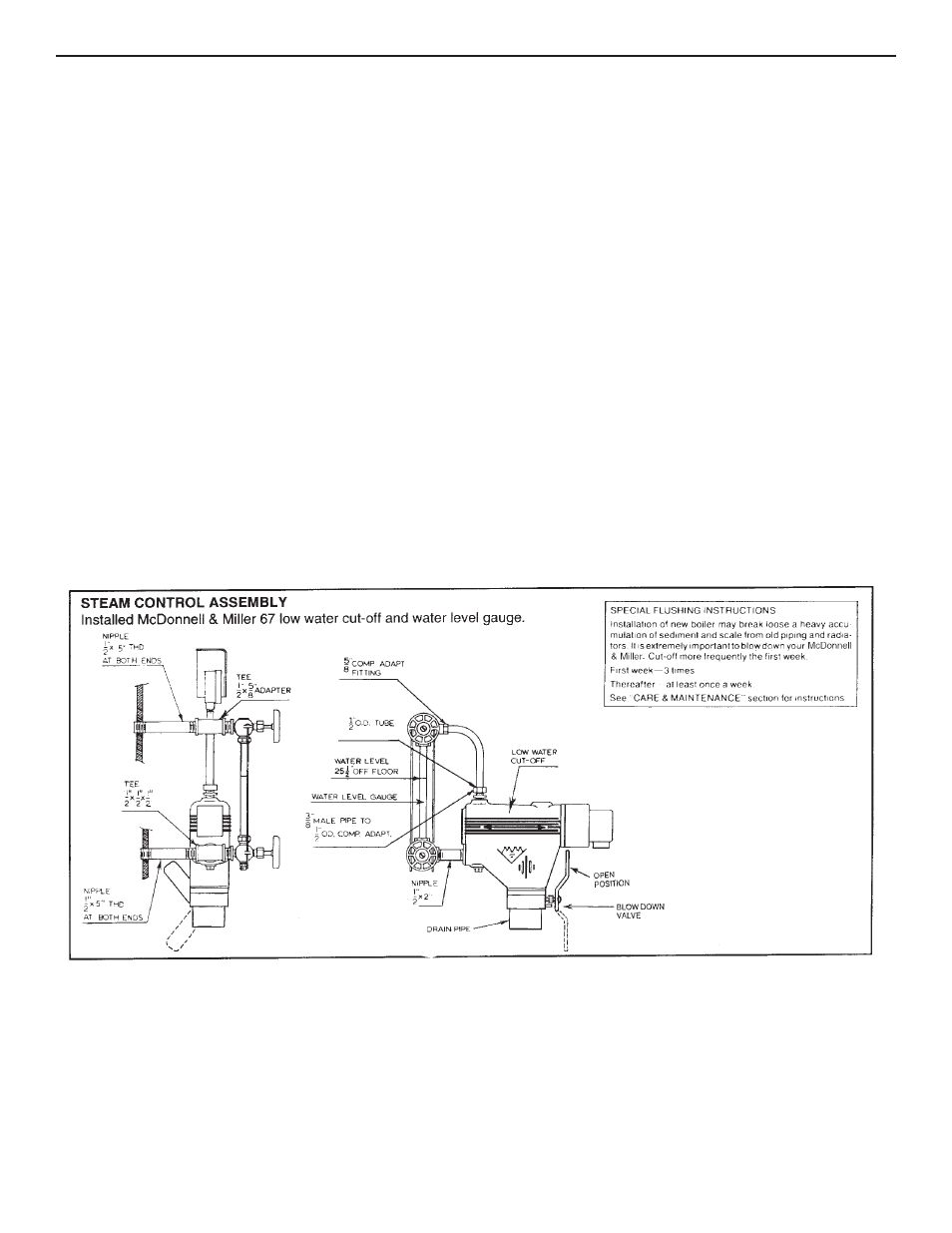

CAUTION: When flushing float type low water cut-off control, hot water

and steam will flow out the blow down valve. Blow down valve is illus-

trated below.

A. SPECIAL FLUSHING INSTRUCTIONS

For new boiler installed in old system.

Installation of new boiler may break loose a heavy accumulation of

sediment and scale from old piping and radiators. It is extremely

important to blow down your McDonnell cut-off more frequently the

first week.

First week — 3 times

Thereafter — at least once a week.

B. As boiler water circulates through the float chamber, dirt or other

sediment may be deposited. This chamber is extra deep. But the

only sure way to keep any accumulation from interfering with float

action is to "blow down", or flush out, the control once a week. Do it

while boiler is in operation. First note water level in gauge glass.

Open blow-off valve at bottom of control; water will pour out, flush-

ing away sediment. Drain until water is clear — about a pail —then

close valve. If level in gauge glass has dropped, add water to boiler

to restore level.

C. NOTE: Opening blow-off valve checks cut-off operation too. As

float drops with falling water level, burner will stop. After burner is

off and normal operating conditions restored, burner will resume

firing.

D. Be sure that it is the low water cut-off and not the room thermostat,

pressure cut-out, or other control that has shut off the burner.

PRESSURE CONTROL CHECK-OUT

A.

Check burner to be certain it is ready for firing. DO NOT FIRE into

an empty boiler.

B.

Set thermostat high enough for boiler to make steam. Set the pres

sure control down to its lowest setting. As the boiler starts to pro-

duce steam, the steam pressure will start to build. The burner will

shut off when the steam pressure exceeds the pressure setting

(plus differential if control has this feature).

C.

Adjust the pressure control to a higher setting. The higher setting

should be above the steam pressure in the boiler. This should turn

the burner back on.

D.

Reset the pressure control as needed for the system. The pressure

control should be checked at least twice a year.

REPLACEMENT OF STEAM BOILERS

Anytime an older steam boiler is removed from the heating system and

replaced with a new boiler, there are certain conditions that have to be

examined on the heating system.

A.

Steam systems have a tendency to develop scale inside the wet

return lines and the boiler. The older the system the greater the

accumulation of scale that can exist inside the piping. Therefore, it

is necessary when replacing a steam boiler to check the piping for

blockage or restrictions. Clean or replace the piping as required.

(See special flushing instructions on this page.)

B.

Replace all buried wet return lines.

C.

All equipment (air vents, radiation equipment, etc.) in the steam

heating system should be checked for proper operation. All piping

should be checked for proper pitch.

D.

It is good engineering practice to repack or tighten the packing nuts

on all valves in the heating system.