Maintenance, Lubrication, General – Woodstock W1737 User Manual

Page 26

-24-

W1737/W1738 Owner's Manual (Mfg. 10/09+)

M

A

INTE

N

A

N

CE

MAINTENANCE

Lubrication

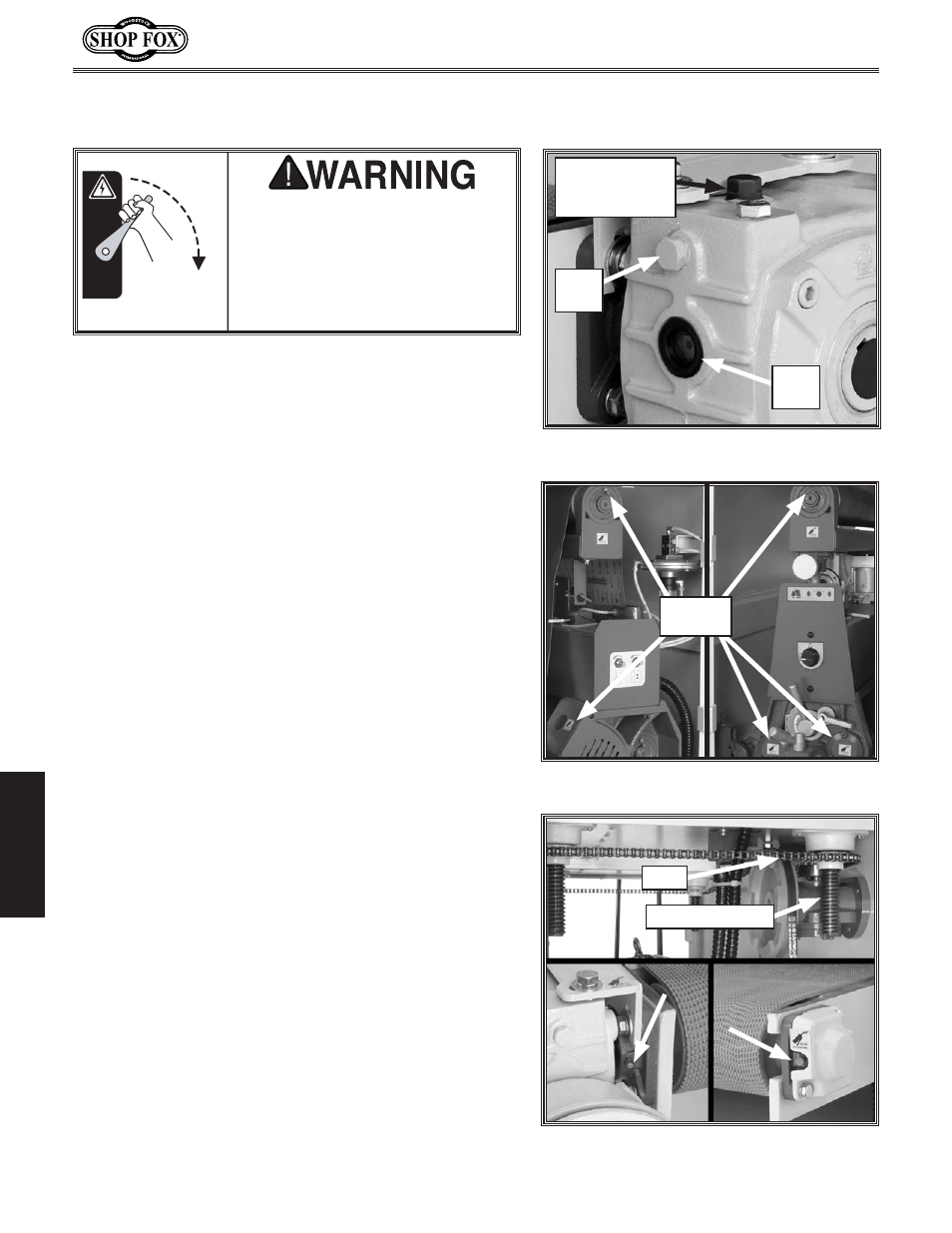

Wipe off all sawdust and abrasives from grease fittings

and plugs before lubrication. When lubricating machine

parts, your goal is to achieve adequate lubrication to

prevent rust, and a thin layer of lubricant to prevent

metal-to-metal friction. Too much lubrication will

attract dirt and sawdust, causing machine parts to bind.

• After the first 300 hours of use, replace the gear

reducer (

Figure 29) lubricant with straight 140W

gear oil (available at most automotive parts stores)

up to the center of the sight glass. DO NOT use the

common 85-140 gear lube as the viscosity is too

low and oil can leak past seals.

• After 2,500 hours of use thereafter, replace the

gear lube and always clean the vented plug (

Figure

29) to make sure it vents the gear case.

• After every 150 hours of use, lubricate the bearings

(

Figure 30 & 31) with one squirt of automotive-

grade grease at the designated points.

• After every 20-40 hours of use, lubricate the

elevation screws with grease, and brush or lightly

spray the table chain and sprockets with a light

coat of oil and wipe any drips off (see

Figure 31).

Regular maintenance on your Model W1737/W1738

ensures optimum performance. Inspect your machine

each time you use it. At the end of the day, remove the

sanding belt and clean the back-side of the sanding belt

and the drum surfaces. Remove wood and abrasive dusts

from the inside of the machine.

General

TURN OFF and LOCK the master

power switch when doing

maintenance so no power is

available to the sander! If you

ignore this warning serious

electrical shock or accidental

start may cause injury or death!

OFF

Figure 29. Gear reducer breather and

filler plug.

Figure 30. Left/right grease fitting

locations.

Figure 31. Conveyor grease fitting

locations.

Filler

Plug

Vented Plug

with Shipping

Pin Removed

Sight

Glass

Lithium Grease

Oil

Grease

Fittings