Emergency stop, Keypad and display calibrating the table – Woodstock W1737 User Manual

Page 21

-19-

W1737/W1738 Owner's Manual (Mfg. 10/09+)

O

PE

R

ATIO

NS

Emergency Stop

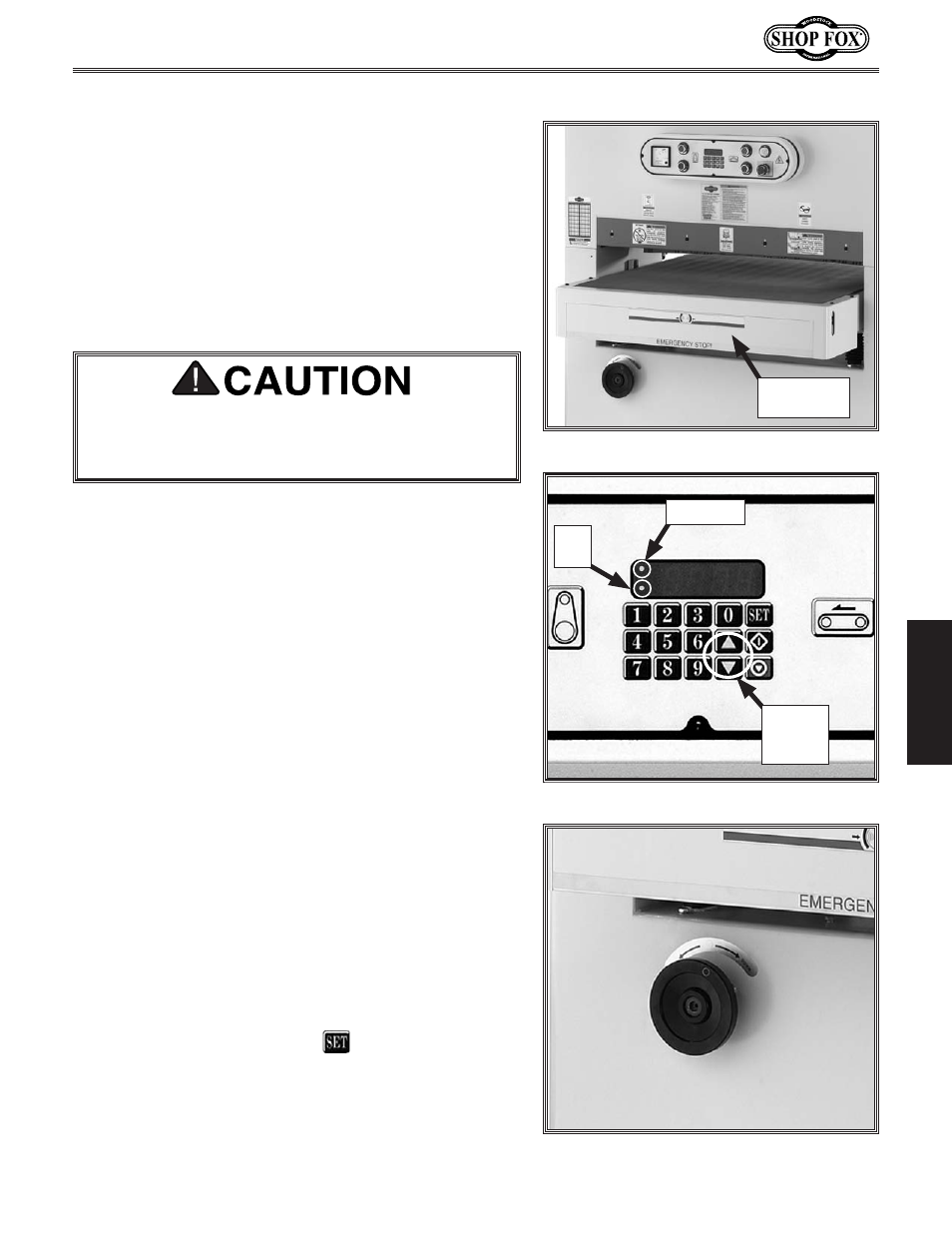

Figure 20. Digital display and key pad.

Figure 21. Table height handwheel.

When pushed, the emergency stop plate shown in

Figure

19 stops the electricity to the motors and also applies

an air-disc brake to stop the sander immediately.

To use the emergency stop, do these steps:

1. Push the bottom of the emergency stop plate.

2. Hold the emergency stop plate until the sander has

come to a complete stop.

Figure 19. Emergency stop plate.

KEEP the sanding drum drive belts correctly adjusted.

Otherwise, the sanding drum pulley will slip when

the emergency brake is applied and not immediately

stop the machine in the event of an emergency!

Keypad and Display

Calibrating the Table

You can push the

UP or DOWN arrow keys to lift or

lower the table, or you can use the automated function

of auto height adjustment for your next sanding pass.

All functions are controlled through the key pad and are

presented on the digital display. See

Figure 20.

Input LED

Run

LED

Up and

Down

Keys

When you change the sandpaper or you notice an

inconsistency with the actual sanding thickness in

relationship to your digital setting, you must re-calibrate

the table.

To re-calibrate your table, do these steps:

1. Sand a workpiece multiple times at the same

thickness until no sanding occurs when the

workpiece goes through the sander.

2. Using a caliper capable of measuring 0.001",

measure and record the workpiece thickness.

3. Type the recorded thickness of the workpiece on

the key pad, and the digital display will show the

thickness.

Example: For 1

1

⁄

2

" thickness, type 1.500;

or for 1

3

⁄

8

" thickness, type 1.375.

4. Now press and hold the SET key for 3 seconds:

The table is now calibrated.

Note: Holding the set key for 10 seconds toggles

the digital readout between metric and standard

measurements.

Emergency

Stop Plate