Operation 6, Troubleshooting – Simer Pumps PORTABLE UTILITY/SPRINKLER PUMP 2825SS User Manual

Page 6

Operation

6

For parts or assistance, call Simer Customer Service at

1-800-468-7867 / 1-800-546-7867

2. Replace all fill plugs.

3. Power on! Start the pump. If you don’t have water

after 2 or 3 minutes, stop the pump and remove the

fill plugs. Refill the pump and piping. You may have

to repeat this several times in order to get all of the

trapped air out of the piping. A pump lifting water 25’

may take as long as 15 minutes to prime.

4. After the pump has built up pressure in the system

and shut off, check the pressure switch operation by

opening a faucet or two and running enough water

out to bleed off pressure until the pump starts. The

pump should start when the pressure drops to 30 PSI

and stop when the pressure reaches 50 PSI. Run the

pump through one or two complete cycles to verify

correct operation. This will also help clean the system

of dirt and scale dislodged during installation.

Congratulations on a successful installation.

If you were unsuccessful, please refer to the

Troubleshooting section (below) or call our customer ser-

vice technical staff at 1-800-468-7867.

Troubleshooting

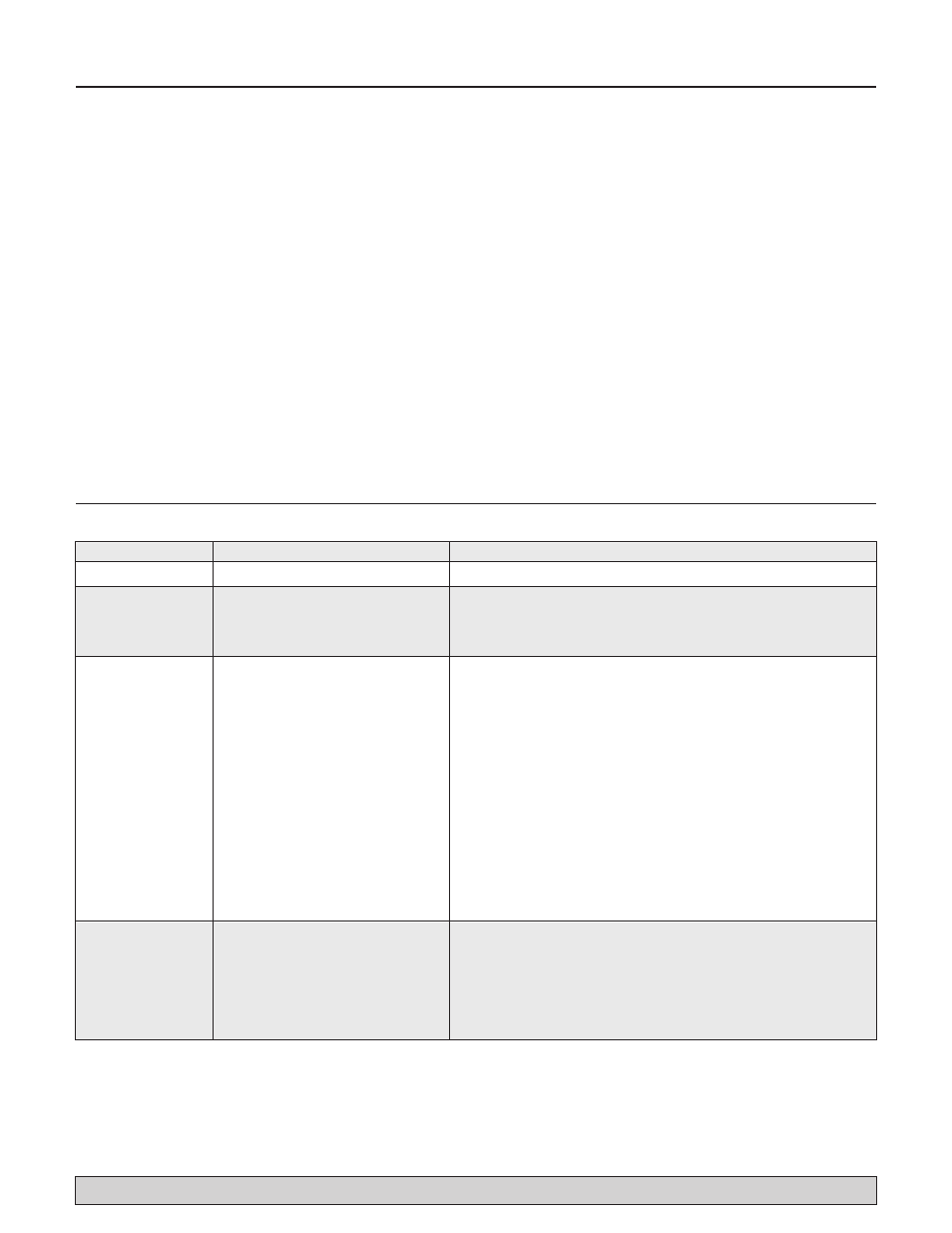

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Motor will not run

Fuse is blown or circuit breaker tripped

DISCONNECT POWER;Replace fuse or reset circuit breaker.

Motor runs hot and

Voltage is too low

Check voltage being supplied to the pump.

the overload kicks

off or the does not

run and only hums.

Motor runs but no

Pump during new installation did

In new installation:

water is delivered*

not pick up prime through:

1. Improper priming

1. Re-prime according to instructions.

2. Air leaks

2. Check all connections on suction line, with soapy water or

shaving cream.

3. Leaking foot valve

3. Replace foot valve.

4. Pipe size is too small

4. Re-pipe using size of suction and discharge ports on pump.

Pump has lost prime through:

In installation already in use:

1. Air leaks

1. Check all connections on suction line and shaft seal with soapy water.

2. Water level below suction pipe inlet

2. Lower suction line into water and re-prime. If receding water level

in well exceeds 25’ (7.6M), a deep well pump is needed.

Impeller is plugged

Clean impeller.

Foot valve is stuck shut

Replace the foot valve.

Pipes are frozen

Thaw pipes.

Foot valve and/or strainer are

Raise the foot valve and/or strainer above bottom of water source.

buried in sand or mud

Clean foot valve and strainer.

*Pump does not

Water being pumped is lower than

A deep well jet will may needed if the water being pumped is more than

deliver water to full

estimated

25’ (7.6M) depth to water.

capacity

Steel piping (if used) is corroded or

Replace with plastic pipe where possible, otherwise with new steel pipe.

limed, causing excess friction

Piping is too small in size

Re-pipe using size of suction and discharge ports on pump.

Pump not being supplied with

Add additional well points.

enough water

* (Note:

Stop pump;

then check prime

before looking for

other causes.

Unscrew priming

plug and see if water

is in priming hole).