Installation 4, Specifications, Shallow well jet pump installations – Simer Pumps PORTABLE UTILITY/SPRINKLER PUMP 2825SS User Manual

Page 4: Replacing an old pump, Boosting city water pressure, Performance sealing pipe joints

For parts or assistance, call Simer Customer Service at

1-800-468-7867 / 1-800-546-7867

Installation

4

SPECIFICATIONS

Power Supply Required. ...................................115 Volts

Motor Duty ...................................................Continuous

Circuit Requirement (minimum) .....................15.0 Amps

Discharge Adapter .......................................................1"

SHALLOW WELL JET PUMP

INSTALLATIONS:

• Have a vertical depth of 25’ or less.

• Have one pipe from the well to the pump case.

• Can be installed in a bored or drilled well, or in a

driven well.

REPLACING AN OLD PUMP

Hazardous voltage. Can shock, burn or

kill. Disconnect power to pump before working on

pump or motor.

This pump can replace shallow well jet pump, Model

3825. This will require reusing the pressure switch and

wiring the pump to the switch.

1. Drain and remove the old pump. Check the old pipe

for scale, lime, rust, etc., and replace it if necessary.

2. Install the pump in the system. Make sure that all

pipe joints in the suction pipe are air-tight as well as

water tight.

If the suction pipe can suck air, the

pump will not be able to pull water from the well.

3. Adjust the pump mounting height so that the plumb-

ing connections do not put a strain on the pump

body. Support the pipe so that the pump body does

not take the weight of piping or fittings.

This completes the well plumbing for your new shal-

low well jet pump. Please go to Page 6 for

discharge pipe and tank connections.

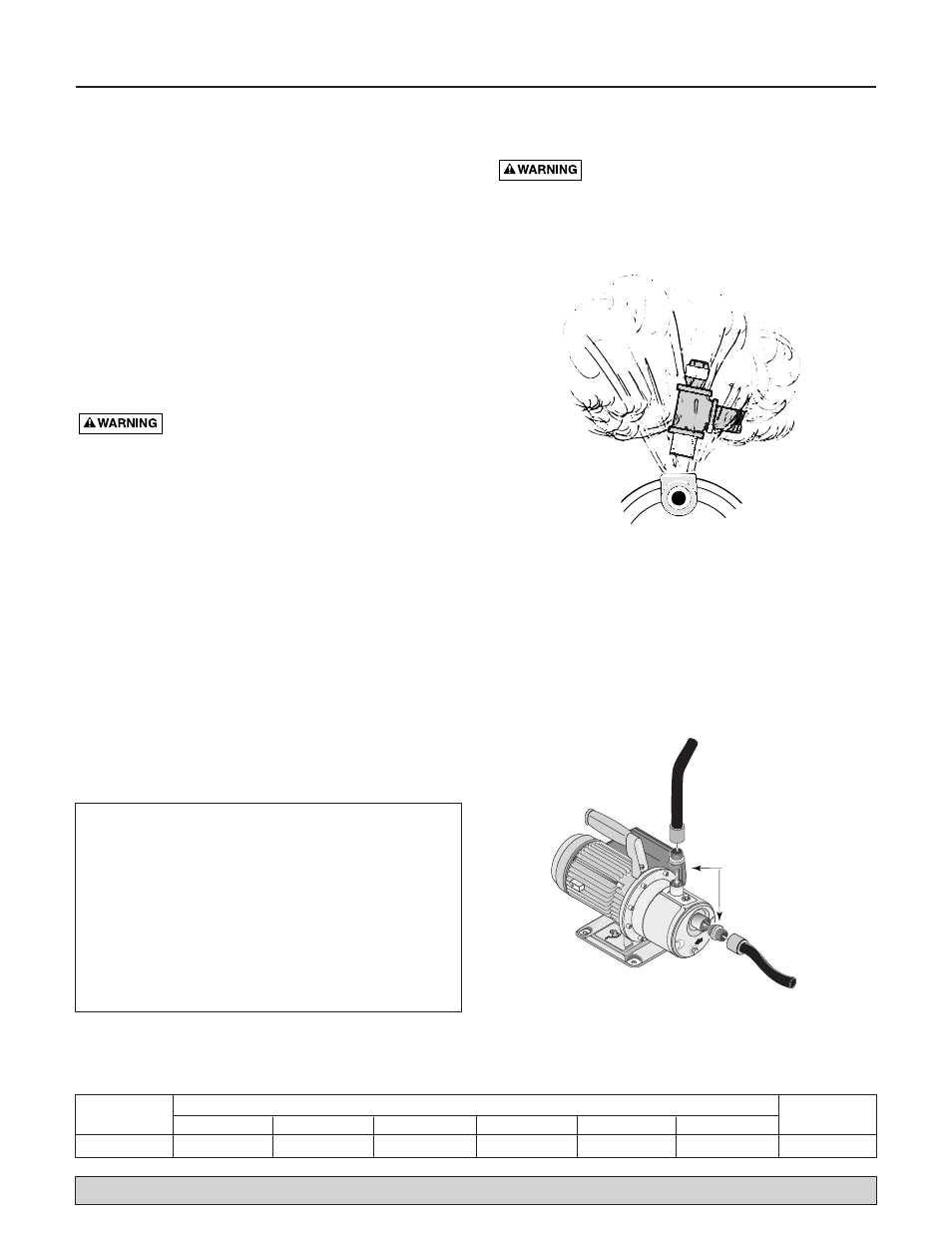

BOOSTING CITY WATER PRESSURE

Hazardous pressure. Never run the pump

against a closed discharge. To do so can boil the water

inside the pump, causing hazardous pressure in the

pump causing the risk of explosion and possibly scald-

ing persons nearby. See Figure 1.

When using the pump as a high-pressure washer, use

only a reinforced high pressure hose or pipe for the dis-

charge line.

When using a garden hose, install adapters to the pump

suction and the discharge. The suction hose will require

two female ends. Either use a standard washing machine

supply hose or modify a short piece of standard 1" gar-

den hose as a suction line (See Figure 2).

Output Pressure

Maximum

Model

0

10

20

30

40

50

PSI

2825ss

10

8.5

8.0

7.5

7.0

6.0

80

PERFORMANCE

Sealing Pipe Joints

Use only Teflon tape for making all threaded

connections to the pump itself. Do not use pipe

joint compounds on plastic pumps: they can

react with the plastic in pump components.

Make sure that all pipe joints in the suction pipe

are air tight as well as water tight.

If the suction

pipe can suck air, the pump will not be able to

pull water from the well.

1117 0993

Figure 1: Do Not Run Pump With Outlet Shut Off

Hose Adapters

Figure 2: Hose adapter installation