Safety 2, Warning, Read and follow safety instructions – Simer Pumps PORTABLE UTILITY/SPRINKLER PUMP 2825SS User Manual

Page 2: General safety, Electrical safety

Safety

2

For parts or assistance, call Simer Customer Service at

1-800-468-7867 / 1-800-546-7867

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

GENERAL SAFETY

1. To avoid risk of serious bodily injury and property

damage, read the safety instructions carefully before

installing this pump.

2. Follow local and/or national plumbing and electrical

codes when installing the pump.

3.

Hazardous Pressure. The pump body

may explode if used as a booster pump unless a

relief valve capable of passing the full pump flow at

60 PSI (414 kPa) is installed. Never run the pump

dry. To do so can damage internal parts, overheat

pump (which can cause burns to people handling or

servicing pump), and will void warranty!

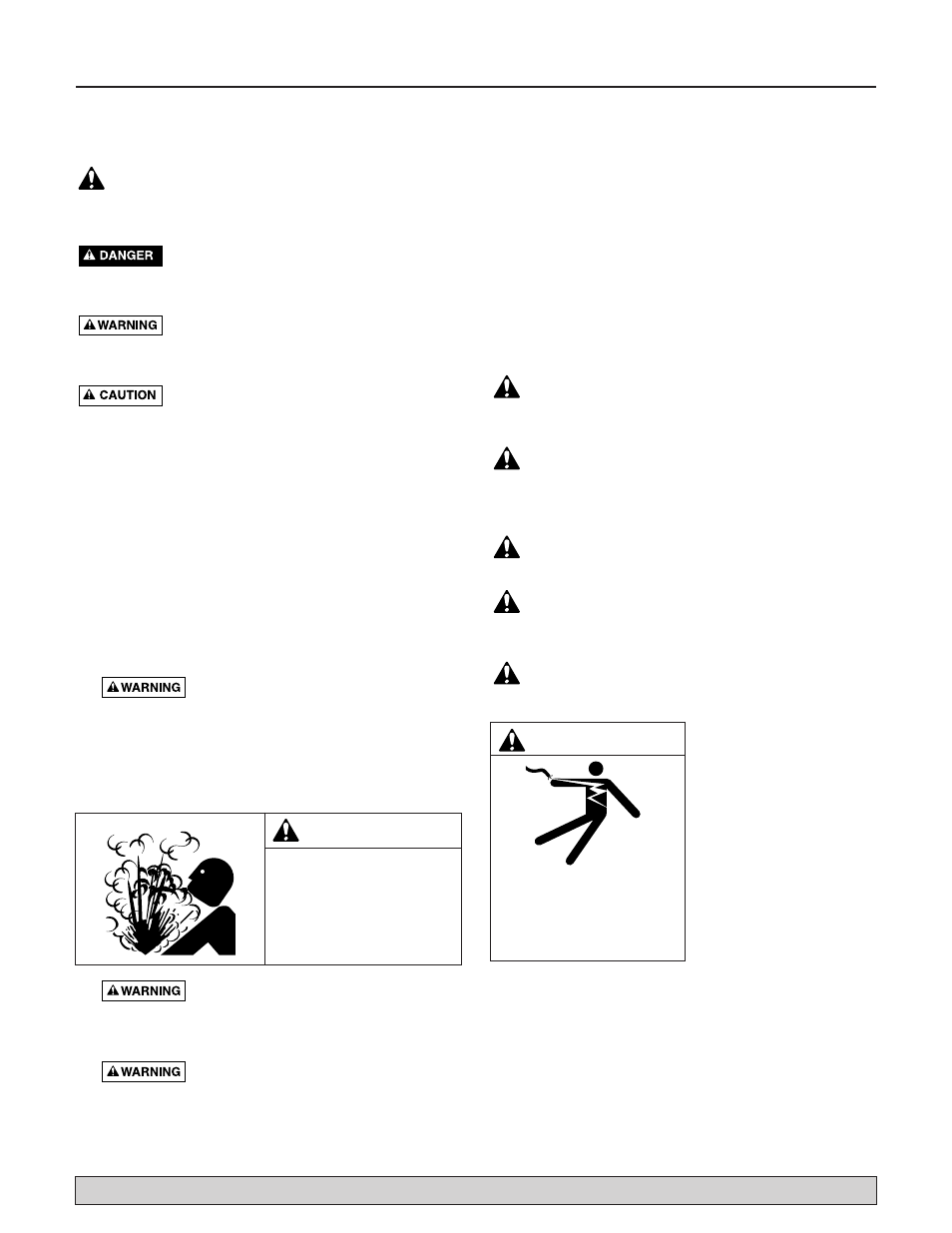

4.

Risk of fire or explosion. To avoid risk

of fire and explosion, Pump Water Only with this

pump. Do not use this pump in an atmosphere that

might contain flammable fumes or vapors.

5.

Burn Hazard. If water is trapped in the

pump during operation it may turn to steam.

Trapped steam can lead to explosion and burns.

Never run the pump with the outlet closed or

obstructed.

6. If used with a well for potable water, always disinfect

the well and test the water for purity before using.

Check with your local health department for testing

procedures.

7. Complete pump and piping must be protected against

freezing. Freezing will cause damage and void the

warranty.

8. This pump is not designed, nor intended, for the

pumping of chemicals or corrosive liquids. Pump

water only with this pump.

9. Do not run pump dry. If the pump is dry, damage will

result and void the warranty.

ELECTRICAL SAFETY

The pump is supplied with a 3-conductor ground-

ing type cord. Connect only to a properly ground-

ed, GFCI protected outlet. Do not lift the pump by the

electrical cord.

Match the motor voltage and the power supply

voltage. The supply voltage must be within +/- 10%

of the motor nameplate voltage. Incorrect voltage can

cause fire or seriously damage the motor and will void

the warranty. If in doubt, consult a licensed electrician.

The pump is non-submersible. Keep the motor dry

at all times. Do not wash the motor. Do not

immerse. Protect the motor from wet weather.

If using an extension cord, use only a UL approved

indoor/outdoor, 3-wire, grounding type cord. Do

not allow any part of the cord or the receptacle ends to

sit in water or in damp locations.

Unplug the pump before servicing. To avoid fatal

shocks, proceed as follows if the pump needs

servicing.

A. Disconnect the power

to the pump outlet box

before pulling the

pump plug. Modern

motors are designed

to operate at high

temperatures. To avoid

burns when servicing

pump, allow it to cool

for 20 minutes after

shut-down before

handling.

B. Take extreme care

when changing fuses.

To reduce the chance of

fatal electrical shocks, DO NOT stand in water or put

your finger in the fuse socket.

C. Ground the pressure switch or motor before before

running this pump.

D. Plug pump into a Ground Fault Circuit Interrupter

(GFCI) protected grounded outlet only.

WARNING

Hazardous voltage. Can

shock, burn, or cause death.

Ground pump before connecting

to power supply. Disconnect

power before working on pump,

motor or tank.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.