Horizontally vented, category iii - figure 15, Standard combustion – Sterling TUBULAR GAS FIRED DIRECT SPARK PROPELLER UNIT HEATERS GG-30 User Manual

Page 21

21

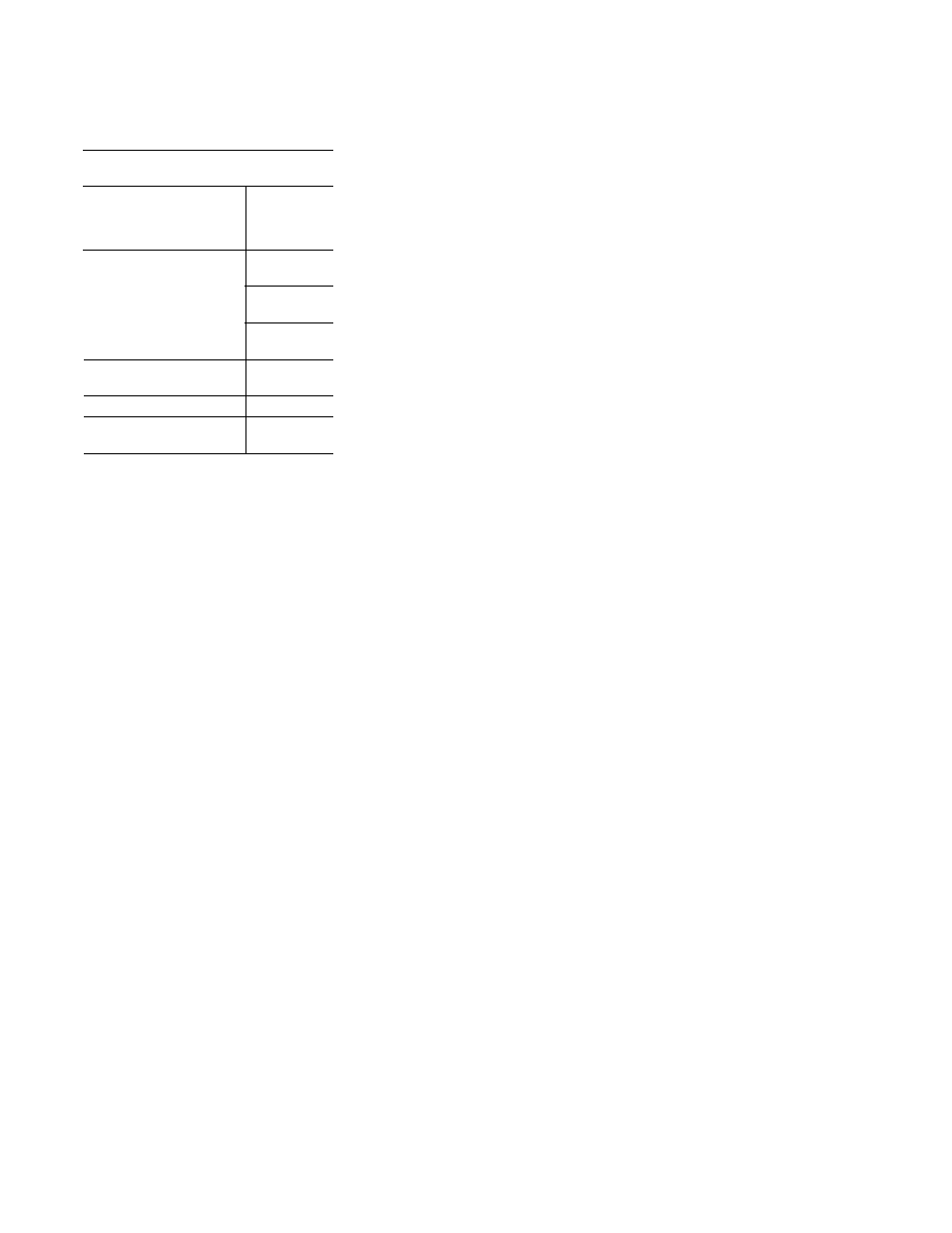

HORIZONTALLY VENTED, CATEGORY III - Figure 15

Observe the following precautions

when venting the unit:

1. Use fl ue pipe of the same size

as the fl ue connection(s) on the

gas unit heater, 4" (102mm). All

heaters must be vented with a

single or double wall pipe listed

for category III positive pressure

vent systems.

Type B double wall pipe can be

used with limitations as shown in

Figure 15B. As illustrated, a

single 5 foot (1.52m) section of

Type B vent pipe with a draft

hood connector may be used

between the appliance vent

connection and the vent terminal.

Use Metalbestos Type B gas

vent with a Metalbestos 4RV-DH

draft hood connector, or, an

Amerivent Type B gas vent with

an Amerivent 4EDC draft hood

connector.

2. Each unit must have an

individual vent pipe and vent

terminal. Unit MUST NOT be

connected to other vent systems

or to a chimney.

3. Category

III units are limited to

a maximum of 40 feet (12.19m)

equivalent length of vent pipe.

Equivalent length is the total

length of straight sections PLUS

5 feet (1.5m) for each 90 degree

elbow and 2.5 feet (.75m) for

each 45 degree elbow.

4. If using a single section of Type

B vent pipe, seal the annular

space between the inner and

outer sections of the draft hood

connector with a high temper-

ature silicone sealant. Use

General Electric RTV-108, Dow-

Corning RTV-732, or equivalent

silicone sealant with a temper-

ature rating of 500 deg. F. See

Figure 15C. Attach the draft

hood connector to the appliance

vent connection with screws

(3 minimum) and seal the joint

with silicone sealant. Install a

Type B vent thimble in the wall.

Inser t the vent pipe through

the thimble and attach it to the

adapter on the appliance. Seal

the joint with silicone sealant or

two wraps of aluminum foil tape.

Install a vent cap on the outlet

pipe and secure with screws (3

minimum).

5. An Amerivent Americap or

Metalbestos vent cap must be

supplied by the customer for

each power vented unit. The vent

pipe diameter must be 4 inches

(102mm).

6. Through the wall venting for

these appliances shall not

terminate over public walkways,

or over an area where the

condensate or vapor could

create a nuisance, hazard, or

could be detrimental to the

operation of regulators, relief

valves, or other equipment, see

Figures 15A, 16 and 18.

7. The vent terminal must be at

least 3 feet (1m) above grade,

or in snow areas, at least 3 feet

above the snow line to prevent

blockage by snow.

8. The vent terminal must be at

least 12 inches (305mm) from

the exterior of the wall that

it passes through to prevent

degradation of the building

materials by fl ue gasses.

9. M a i n t a i n 1 - i n c h ( 2 5 . 4 m m )

clearance between the vent

pipe and combustible materials.

10. Seal all vent pipe joints and

seams to prevent leakage. Use

General Electric RTV-108, Dow-

Corning RTV-732, or equivalent

silicone sealant with a temper-

ature rating of 500 deg.F, or 3M

#425 aluminum foil tape (or

equivalent). The vent system

must be installed to prevent

collection of condensate. Pitch

horizontal pipes downward 1/4

inch per foot (21mm per meter)

toward the outlet for condensate

drainage. Install a tee with a

condensate drain at the low point

of the pipe (see Figure 15A). As

an alternate, a 3/8 inch diameter

hole may be drilled at the low

point of the pipe for condensate

drainage.

11. Horizontal portions of the venting

system shall be supported at

minimum intervals of 4 feet

(1.2m) to prevent sagging (in

Canada, support at 3 foot (1m)

minimum intervals).

12. Avoid running vent pipe through

unheated spaces. When this

cannot be avoided, insulate the

pipe to prevent condensation

of moisture on the walls of the

pipe.

Door, window or

any gravity air inlet

Forced air inlet within 10 ft.

Adjoining building or parapet

Adjacent public walkways

Minimum

Clearances for

Termination

Locations

Structure

4 feet

below

4 feet

horizontally

1 foot

above

3 feet

above

6 feet

7 feet

above grade

Vent Systems

Termination Clearance Requirements

STANDARD COMBUSTION

- TUBULAR GAS FIRED DIRECT SPARK PROPELLER UNIT HEATERS GG-60 TUBULAR GAS FIRED DIRECT SPARK PROPELLER UNIT HEATERS GG-105 TUBULAR GAS FIRED DIRECT SPARK PROPELLER UNIT HEATERS GG-120 TUBULAR GAS FIRED DIRECT SPARK PROPELLER UNIT HEATERS GG-45 TUBULAR GAS FIRED DIRECT SPARK PROPELLER UNIT HEATERS GG-75 TUBULAR GAS FIRED DIRECT SPARK PROPELLER UNIT HEATERS GG-90