Maintenance – Servis-Rhino FM84 User Manual

Page 86

Maintenance Section 5-4

FM84 08/01

© 2004 Alamo Group Inc.

MAINTENANCE

MAINTENANCE

DRIVELINE LUBRICATION

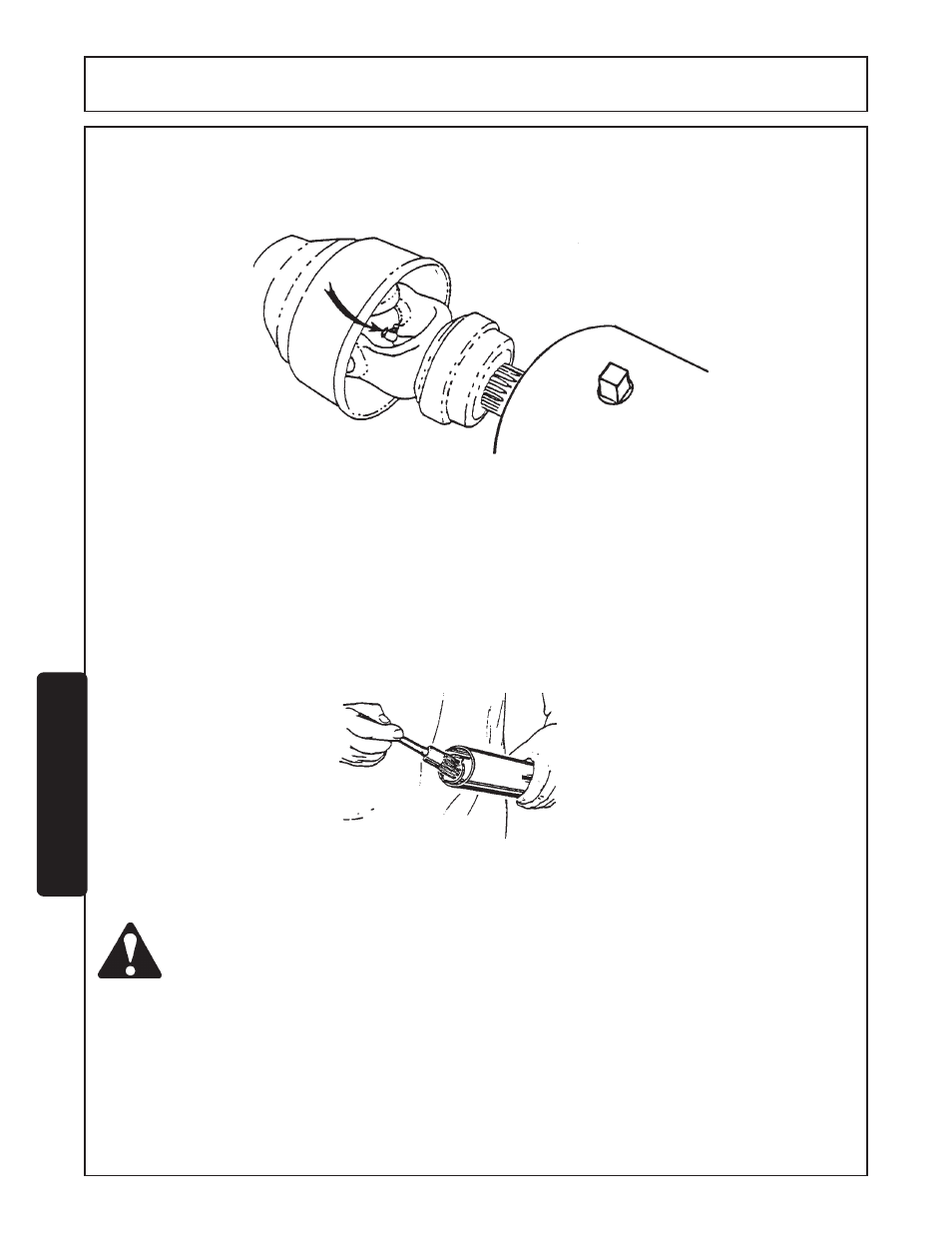

Grease Fittings are located on the Cross Assembly of each U-Joint. Grease the U-Joint after each 8 hours of use.

Figure 4. Do not force grease through the Needle Cup Assemblies.

WARNING!

When attaching PTO yoke to tractor PTO shaft, it is important that the spring-activated locking

collar slides freely and locking balls are seated on the groove on PTO shaft. A loose yoke could

slip off and result in personal injury or damage to cutter.

BLADE SPINDLE LUBRICATION

Blade spindles must be lubricated daily (every 8 hrs). Access lubrication fitting through hole in outer shields and

in center gearbox mounting. Each spindle will vent excess grease through top seal under drive sheave. Spindle must

be lubricated enough to expell a small amount of grease. NOTE: Do not over lube as excess grease may get

on belt drive.

The telescoping PTO shaft inside the shielding must be lubricated daily. Figure 5.

Disconnect driveline from tractor and pull halves apart. Insert grease into outer profile cavity on half attached to

gearbox and spread evenly. Install driveline halves together.

Reconnect driveline to tractor. Raise and lower cutter after applying grease to spread over joint working area.

FIGURE 5

FIGURE 4