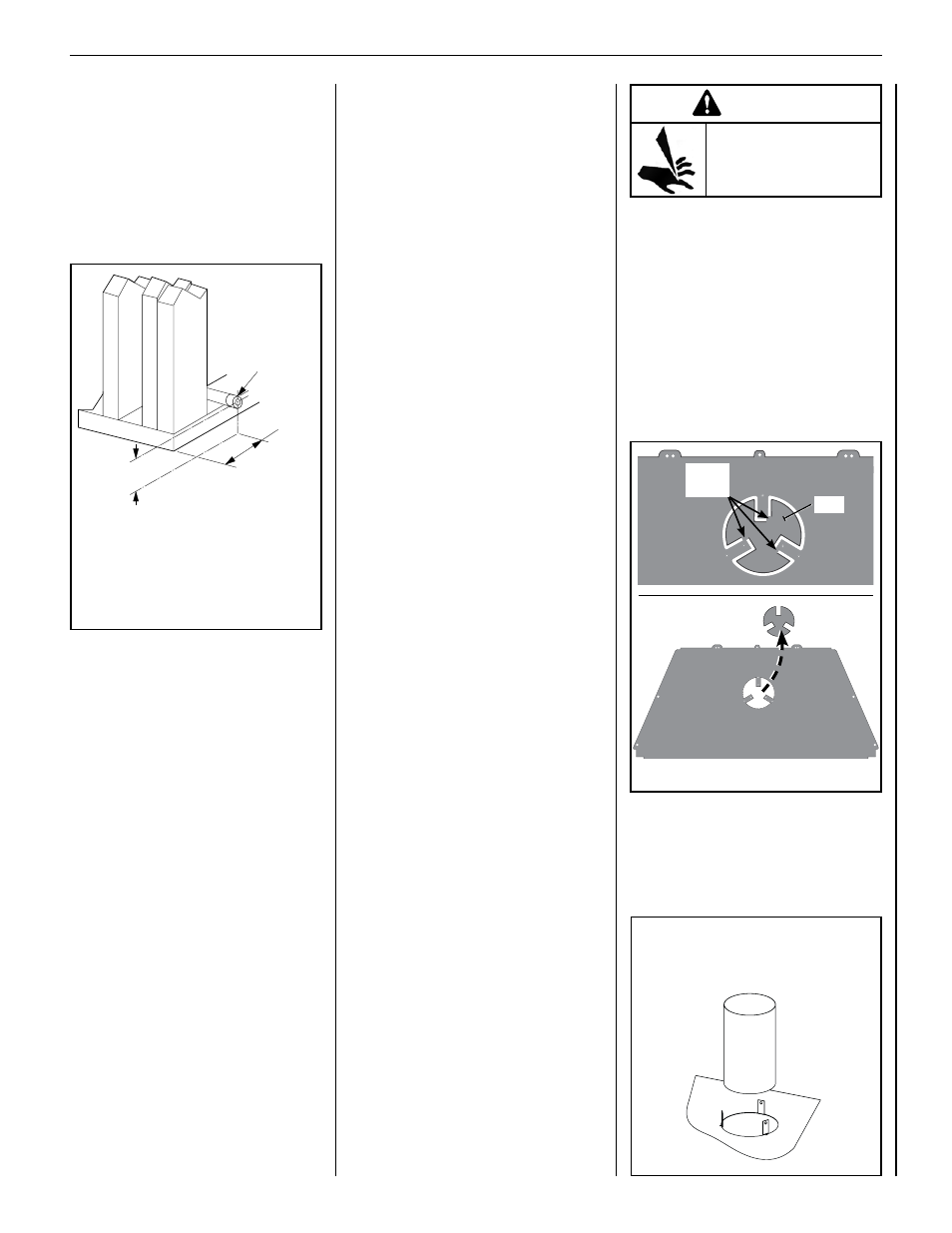

Warning, Sharp edges. watch your fingers – Superior SLBV-40PM User Manual

Page 11

Note:

• All appliances are factory-equipped with

a flexible gas line connector and 1/2 inch

shutoff valve (see Figure 17 on Page 15).

• See Massachusetts Requirements on Page

4 for additional requirements for installa-

tions in the state of Massachusetts in the

USA.

• The gas supply line should NOT be con-

nected to the appliance until Step 6 on Page

15).

• A pipe joint compound rated for gas should

be used on the threaded joints. Ensure that

propane-resistant compounds are used in

propane applications. Be very careful that

the pipe compound does not get inside the

pipe.

• It is recommended to install a sediment trap

in the supply line as close as possible to the

appliance. Appliances using propane should

have a sediment trap at the base of the tank.

• Check with local building official for local

code requirements (e.g., whether below-

grade penetrations of the gas line are al-

lowed, etc.).

IMPORTANT: If propane is used, be aware that

if the tank size is too small (i.e., under 100 lbs

if this is the only gas appliance in the dwell-

ing; ref. NPFA 58), there may be pressure loss

resulting in insufficient fuel delivery, which

can result in sooting, severe delayed ignition,

or other malfunctions. Any damage resulting

from an improper installation, such as this, is

not covered under the limited warranty.

Proper Sizing of Gas Line

Properly size and route the gas supply line

from the supply regulator to the area where the

appliance is to be installed per requirements

outlined in the National Fuel Gas Code, NFPA

54 - latest edition (USA) or CAN/CSA-B149.1 -

latest edition (Canada).

NOTE: Gas line can be routed to either

side. Reverse this illustration if routing

to right side.

Also see Figures 8-1 and 8-2.

Figure 9: Route Gas Line

3"

(76 mm)

Left Side Front

Corner of Fireplace

Framing

6-1/2"

(152 mm)

Pipe Coupling

(Recommended)

Step 2. Route the Gas Line

Route a 1/2" (13 mm) gas line to either side

of the appliance (left side routing is shown

in Figure 9 ). Gas lines must be routed, con-

structed, and made of materials that are in strict

accordance with local codes and regulations.

All appliances are factory-equipped with a flex-

ible gas line connector and 1/2-inch shutoff

valve. (See Step 6 on Page 15.)

Never use galvanized or plastic pipe. Gas lines

must be routed, constructed and made of ma-

terials that are in strict accordance with local

codes and regulations.

IMPORTANT: It is critical that a licensed

installer perform this step strictly per

NFPA.

We recommend that a qualified, licensed

plumber or gas fitter be hired to correctly size

and route the gas supply line to the appliance.

Installing a gas supply line from the fuel supply to

the appliance involves numerous considerations

of materials, protection, sizing, locations, con-

trols, pressure, sediment, and more. Certainly no

one unfamiliar and unqualified should attempt

sizing or installing gas piping.

SUPERIOR

®

B-VENT GAS FIREPLACES • MODELS SLBV-35, SLBV-40 • INSTALLATION INSTRUCTIONS

Step 3. Install Venting System

and Exterior Termination

These instructions should be used as a

guideline and do not supercede local codes

in any way.

Install venting according to local codes, these

instructions, the current National fuel Gas

Code in the USA (ANSI-z223.1) or the current

standards in Canada (CAN/CSA-B149.1).

SLBV-35 and SLBV-40 series fireplaces must

be vertically vented using listed type-B,

double-walled vent pipe with the proper

diameter (as listed below) and a listed vent

termination.

Required Pipe diameter

SLBV-35 series: Requires 4 in. (102 mm)

SLBV-40 series: Requires 5 in. (127 mm)

Figure 10b

Type B-Vent

SLBV-35 models: 4 in. (102 mm)

SLBV-40 models: 5 in. (127 mm)

WARNING: EDGES OF SHEET METAL ARE

SHARP! WEAR PROTECTIVE GLOVES AND USE

EXTREME CARE WHEN HANDLING.

Required tools:

• Sheet Metal-resistant Gloves

• Tin Snips

1. Using tin snips, cut the three connecting

points securing the slug to the three tabs

in the flue collar (as shown in Figure 10a),

and remove the slug.

Carefully dispose of slug in an appropriate

container.

2. Connect the proper size Type B-vent system

to the fireplace flue collar by bending up the

three tabs and securing with three sheet

metal screws (No. 8 or larger) bend up tabs.

See Figure 10b. Then install the remainder

of the Type B-vent to the outside.

Slug

11

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

WARNING

Sharp Edges.

Watch Your Fingers!

Figure 10a

Cutting

points