Troubleshooting – SeaLand 1 2500 Series User Manual

Page 10

10

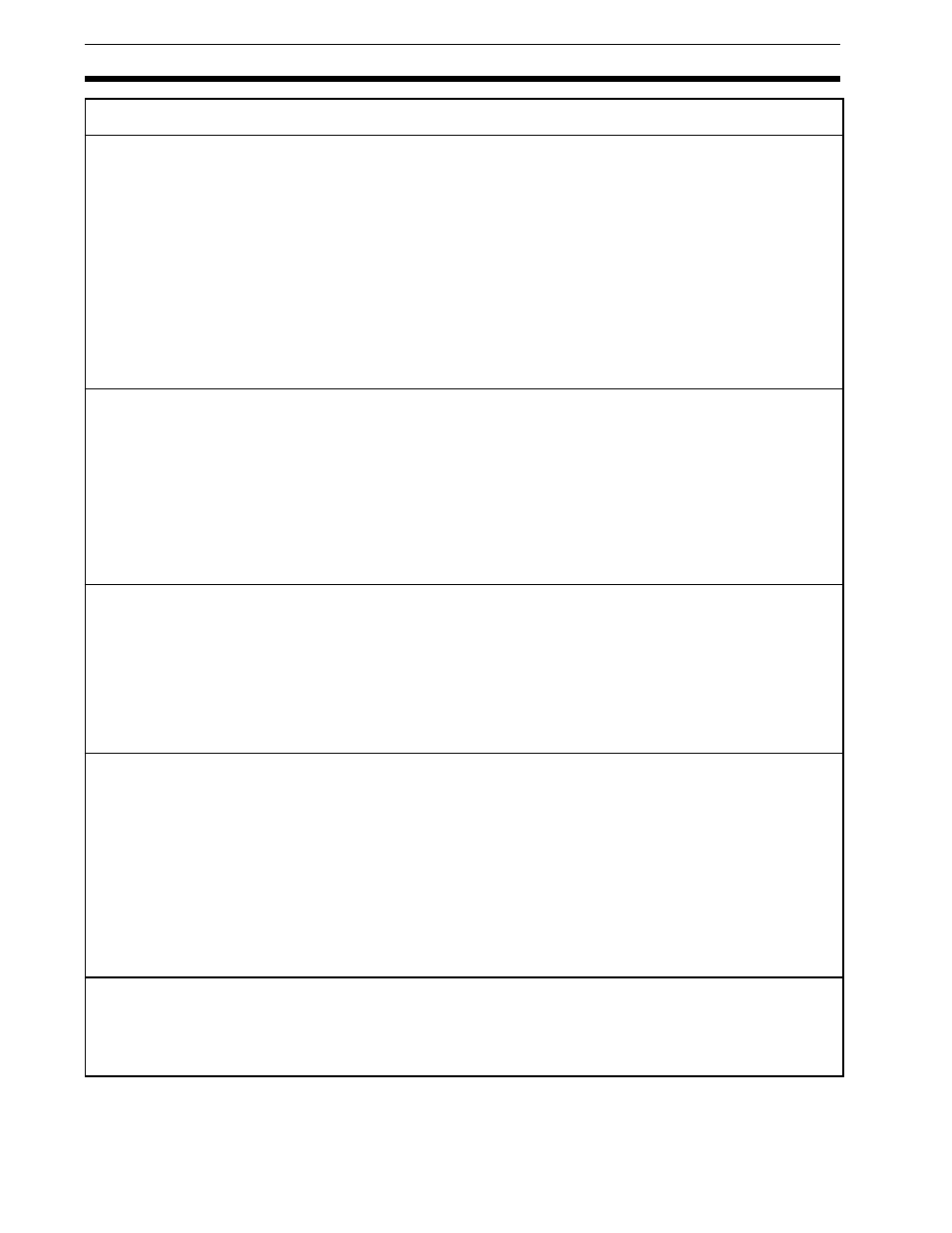

TROUBLESHOOTING

1. Vacuum pump will not run.

2. Vacuum pump will not

shut off.

3. Vacuum pump is running too

slow, overheating, blowing

fuses or circuit breaker.

4. Toilet will not flush.

5. Tank will not discharge us-

ing dockside pump (model

2520/2521).

a. No electrical power.

b. Loose or broken electrical wiring.

c. Improper electrical connections.

d. Faulty vacuum switch.

e. Faulty motor.

f. Shut-down relay prevents pumping.

g. Replace motor.

h. Cassette tank not fully engaged in

docking platform.

a. A vacuum leak exists in system.

b. Insufficient vacuum (pump creates less

than 10 inches Hg).

c. Faulty vacuum switch (pump creates

more than 10 inches Hg).

d. Diaphragm not pumping.

e. Blockage in inlet of vacuum pump.

a. Motor is worn or defective.

b. Plugged vent line or vent filter.

c. Improper wire size.

d. Improper voltage.

e. Vacuum pump clogged with tissue.

a. There is a blockage in the toilet.

b. Hose between toilet and cassette tank

is collapsed or kinked.

c. Foreign objects were flushed, causing

blockage in system.

d. Pump will not run.

a. Tank is not adequately vented.

b. Blockage in check valve at tank outlet.

c. Blockage at bottom of discharge

diptube inside the tank.

a. Check input power, circuit breaker

and fuse.

b. Tighten or reconnect wires at docking

platform.

c. Be sure power wires and wires at

vacuum switch are connected to

proper terminals.

d. Replace vacuum switch.

e. Replace motor.

f. Empty the cassette tank. If cassette

is not seated in docking platform

properly, put cassette tank back into

docking platform until locking latch

engages.

g. Charge battery.

h. Engage cassette tank until latch

secures tank to platform.

a. Check for vacuum leaks in system

with vacuum gauge tester.

b. Isolate cassette tank (remove elbow

assembly) and use vacuum gauge to

check vacuum capability. Could be

worn valves.

c. Replace vacuum switch.

d. Tighten set screw in eccentric to mo-

tor shaft. Otherwise, check for dam-

age to diaphragm and motor shaft.

Replace if necessary.

e. Clear blockage from pump inlet.

a. Check motor and replace if

necessary.

b. Disassemble and clean out vent line.

Replace vent filter if

necessary.

c. Wire size too small. Check

“Electrical Installation” section

for proper wire size.

d. Check input power for low voltage.

e. Remove and clean pump

assembly.

a. Open flush ball and check the

1-inch (25mm) orifice at the bottom of

the base for blockage and dislodge it.

Never use drain-opening or other

household plumbing chemicals.

b. Inspect hose and replace if collapsed

or kinked.

c. Clear foreign objects from system.

DO NOT flush any non-dissolving

items (i.e. sanitary napkins, facial

tissue, wet strength tissue, paper

towels, etc.) or excessive tissue.

Before flushing solids, be sure to add

water by lifting the flush lever.

d. See problem 1.

a. Open flush valve in toilet by pressing

on pedal.

b. Disassemble the check valve and

remove blockage.

c. Remove diptube from tank and clear

blockage.

Problem

Possible Cause

Service Instructions

TROUBLESHOOTING