10/15-hour maintenance general maintenance, Daily maintenance, Hour maintenance – Shindaiwa 81010 User Manual

Page 14

14

10/15-Hour Maintenance

General Maintenance

IMPORTANT!

MAINTENANCE, REPLACEMENT OR

REPAIR OF EMISSION CONTROL

DEVICES AND SYSTEMS MAY BE

PERFORMED BY ANY REPAIR ESTAB-

LISHMENT OR INDIVIDUAL; HOWEVER,

WARRANTY REPAIRS MUST BE PER-

FORMED BY A DEALER OR SERVICE

CENTER AUTHORIZED BY SHINDAIWA

KOGYO CO., LTD. THE USE OF PARTS

THAT ARE NOT EQUIVALENT IN PER-

FORMANCE AND DURABILITY TO

AUTHORIZED PARTS MAY IMPAIR THE

EFFECTIVENESS OF THE EMISSION

CONTROL SYSTEM AND MAY HAVE A

BEARING ON THE OUTCOME OF A

WARRANTY CLAIM.

NOTE:

Using non-standard replacement parts could

invalidate your Shindaiwa warranty.

WARNING!

Non-standard parts may not operate

properly with your unit and may cause

damage and lead to personal injury.

WARNING!

Before performing any maintenance,

repair or cleaning work on the unit,

make sure the engine and cutting

attachment are completely stopped.

Disconnect the spark plug wire before

performing service or maintenance

work.

Muffler

This unit must never be operated with a

faulty or missing spark arrester or muf-

fler. Make sure the muffler is well secured

and in good condition. A worn or damaged

muffler is a fire hazard and may also cause

hearing loss.

Spark Plug

Keep the spark plug and wire connections

tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except

carburetor adjusting screws) are tight.

WARNING!

Never repair a damaged blade by

welding, straightening, or by modify-

ing its shape. An altered blade may

break during operation, resulting in

serious personal injury.

DO NOT use 2-tooth or non-

Shindaiwa approved 4-tooth cutting

blades on Shindaiwa trimmers or

brushcutters.

Blades are

not interchangeable

between Shindaiwa edgers and

trimmer/brushcutter models.Operat-

ing any unit with a blade or attach-

ment not approved for that unit

can be hazardous and may cause

serious injury.

Daily Maintenance

Check for loose or missing screws or

components. Make sure the tool and cut-

ting attachment are securely fastened.

Check the entire unit for leaking fuel or

grease.

Remove dirt or debris from the engine,

check the cooling fins and air cleaner for

clogging and clean them as necessary.

Carefully remove any accumulation of

dirt or debris from the muffler or the

fuel tank. Dirt build-up in these areas

could cause engine overheating, induce

premature wear, or create a fire hazard.

Remove and clean

or replace the element.

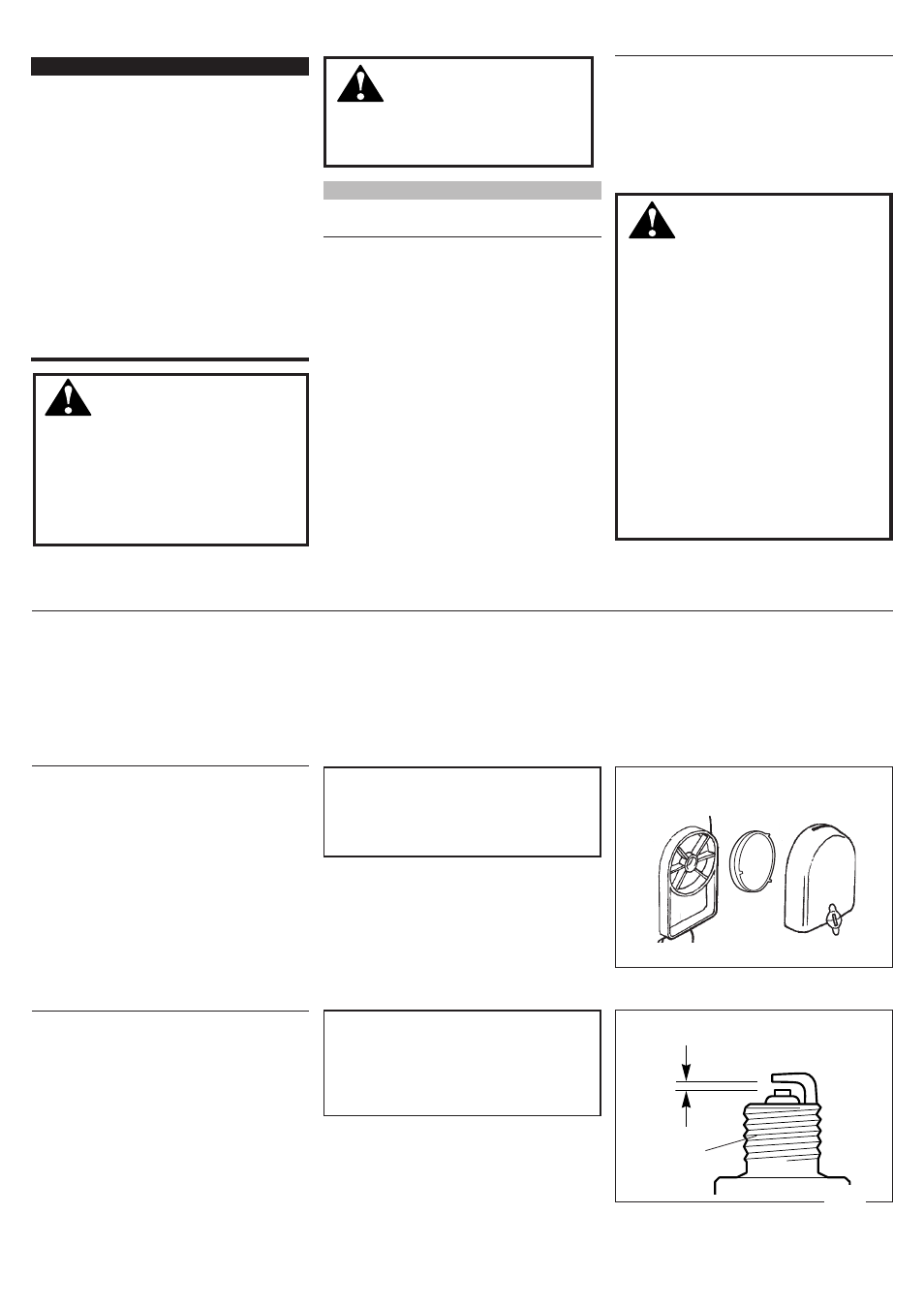

10-Hour Maintenance

Every 10 hours of operation

(more frequently in dusty or dirty

conditions):

Remove the air cleaner element. See

Figure 27. Clean or replace as neces-

sary. To clean element: Wash it thor-

oughly in soap and water. Let it dry

before reinstalling the element.

CAUTION!

Do not operate the unit if the air

cleaner or element is damaged, or if

the element is wet.

Every 10 to 15 hours of operation:

Remove and clean the spark plug. Adjust

the spark plug electrode gap to 0.024-

inch (0.6 mm). If the spark plug must be

replaced, use only a Champion CJ8Y

or equivalent spark plug of the correct

heat range. (For electro-magnetic com-

pliance [EMC] use an NGK BMR6A

resistor plug.) See Figure 28.

CAUTION!

Before removing the spark plug, clean

the area around the plug to prevent dirt

and debris from getting into the internal

engine parts.

27030

0.024"

(0.6mm)

CJ8Y

Figure 27

Figure 28

Blades

Keep blades sharp and check blade

condition frequently. If a blade’s perfor-

mance changes suddenly, stop the engine

and check the blade for cracks or other

damage. Replace a damaged blade

IMMEDIATELY!

Prior to each work day, perform the following:

Clean the spark plug

and check the gap at the

electrode.