Lubrication chart -6, Bolt torque values -6, Maintenance – Servis-Rhino DM124 User Manual

Page 94: Proper torque for fasteners, Lubrication chart

MAINTENANCE

DM 07-02

Maintenance Section 5-6

© 2004 Alamo Group Inc.

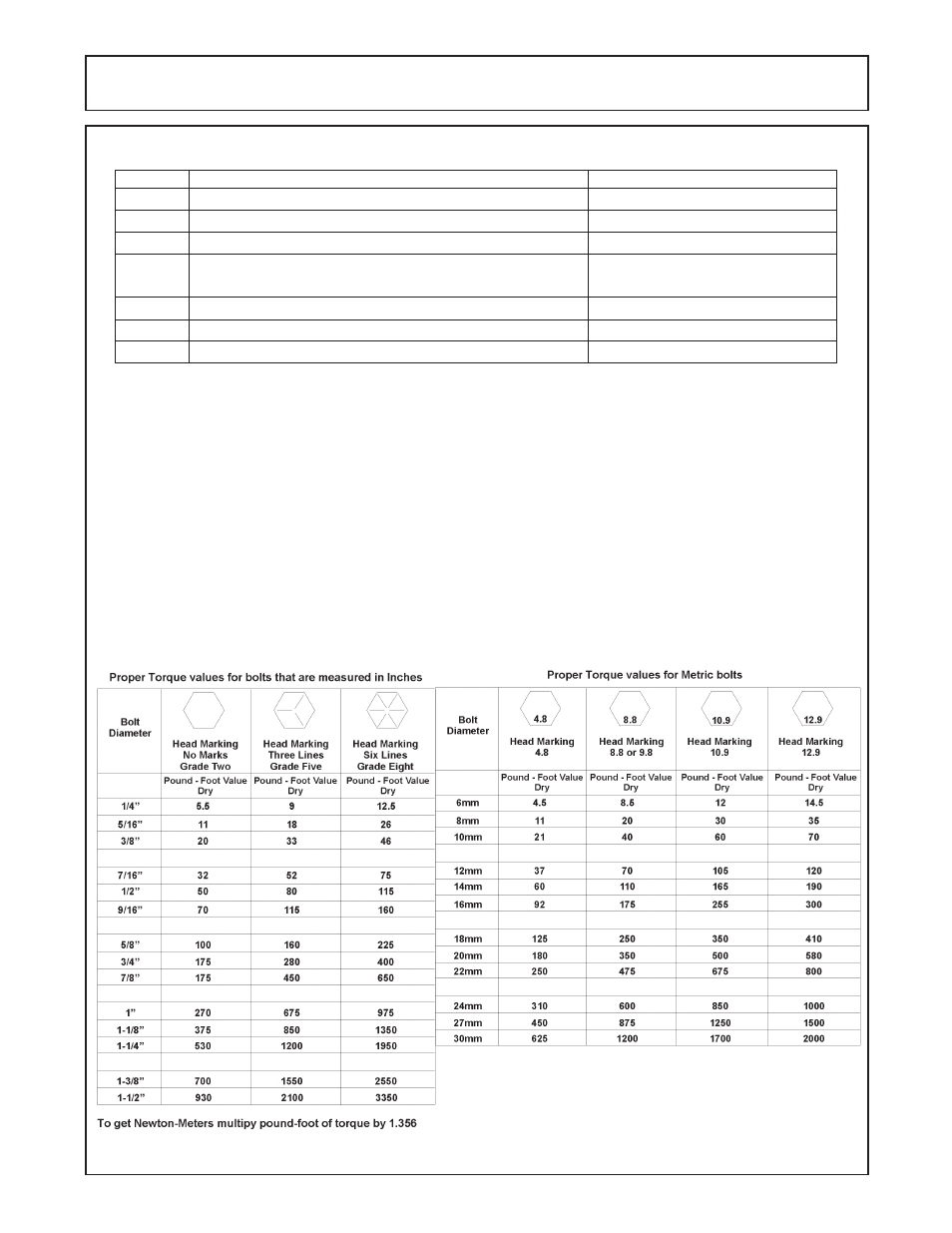

PROPER TORQUE FOR FASTENERS

Because of the severe operating conditions, correct bolt torque is very important. An improperly torqued bolt

can be easily shaken loose or broken by the vibrations. When replacing bolts, always use the same grade of

bolt as used originally. Use this chart as a guide to tightening all bolts. Torque values listed are for general use

only.

Lubrication Chart

Location

Description

Lubrication Frequency

1

Front IID U-joint

After Every 8 Hours of Operation

2

Rear IID U-joint

After Every 8 Hours of Operation

3

IID Shaft Slip Joints

After Every 8 Hours of Operation

4

Gearboxes and Cutter Bar, Fill to respective Level Check Level After Every 8 Hours

Plug w/SAE EP90 or Equivalent Gear Lube

of Operation

5

Main Frame Pivot Point

Daily

6

All Sliding Sections

After Every 8 Hours of Operation

7

All Pivots & Linkage

After Every 8 Hours of Operation

NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal engine oil.

They do not apply if special graphited or molydisulphide greases or other extreme pressure lubricants are used.

This applies to both UNF fine and UNC coarse threads.

RECOMMENDED TORQUE IN FOOT POUNDS UNLESS OTHERWISE STATED IN THE MANUAL

*

FIGURE 18

*