Piezoelectric igniter system, Testing the igniter system – State GS6 30 YOCT User Manual

Page 28

28

tight in the gas control valve/thermostat. Finally, start

the thermocouple nut and turn it all the way in by hand.

An additional quarter turn with a 3/8” open-end wrench

will then be sufficient to seat the lockwasher. When

you are finished, connect the two wire leads that go to

the thermal switch.

7. Reconnect the igniter wire.

8. Turn gas supply on and refer to the Lighting Instruc-

tions.

9. With the burner lit, check the gas control valve/

thermostat supply line, two piece wire connector,

manifold tube, and pilot tube connections for

leaks. Check for leaks by brushing on an approved

noncorrosive leak detection solution. Bubbles forming

indicate a leak. Correct any leak found. IMPORTANT:

All leaks must be fixed immediately.

10. Replace the outer door.

DOOR GASKET

FLAME ARRESTOR

BRACKET

TIP

FIGURE 30.

MANIFOLD TUBE

TIP

BRACKET

SLOT

CLOSE-UP INSIDE VIEW OF

THE COMBUSTION CHAMBER.

FIGURE 31.

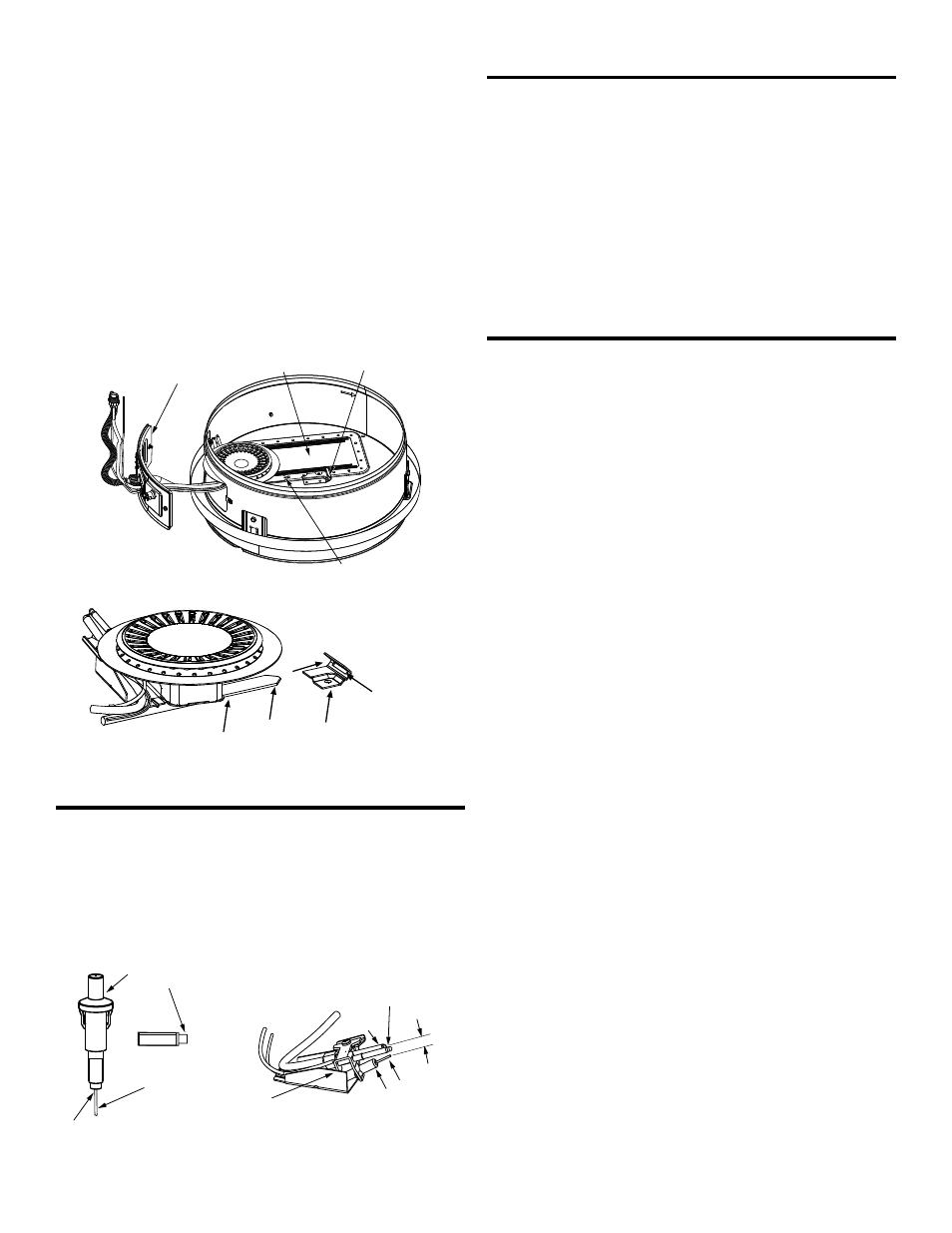

Piezoelectric Igniter System

The piezoelectric igniter system consists of the igniter

button, electrode, and wire. The pilot is ignited by an

electric spark generated when the igniter button is

pressed. The spark gap of 0.125 inch is set when the

electrode is installed at the factory. (Figure 32 ). Use

only factory authorized piezoelectric igniter parts for

replacement.

SNAP-ON CONNECTOR

IGNITER

BUTTON

WIRE

TO

ELECTRODE

THERMOCOUPLE

PILOT

PILOT

BRACKET

ELECTRODE

TIP

.125” *

* NOTE: SPARK GAP DISTANCE MEASURED FROM ELECTRODE TIP TO PILOT.

FIGURE 32.

Testing the Igniter System

Turn off the gas to the water heater at the manual gas

shut-off valve. Watch the electrode tip while activating the

igniter. A visible spark should jump from the electrode. To

avoid shock, do not touch the burner or any metal part

on the pilot or pilot assembly. If no spark is visible, check

the wire connections and make sure the electrode is not

broken. Replace the igniter if defective. Dirt and rust on the

pilot or electrode tip can prevent the igniter spark. Wipe

clean with a damp cloth and dry completely. Rust can be

removed from the electrode tip and metal surfaces by

lightly sanding with an emery cloth or fine grit sandpaper.

Removing and Replacing the Gas Control

Valve/Thermostat

IMPORTANT: This water heater has a resettable thermal

switch installed. Do not attempt to disable or modify this

feature in any way. Use only factory authorized

replacement parts.

Removing the Gas Valve:

1. Turn off the gas supply to the water heater at the

manual gas shut-off valve. This valve is typically located

beside the water heater. Note the position of the shut-

off valve in the open/on position then proceed to turn it

off (Figure 3).

2. On the lower front of the water heater locate the

gas control valve/thermostat (see Figure 23). Before

performing any maintenance, it is important to turn the

temperature dial on the gas control valve/thermostat to

its lowest setting.

3. On top of the gas control valve/thermostat turn the gas

control knob to the “OFF” position. NOTE: On the White

Rodgers gas control valve/thermostat the knob stop

must first be depressed before turning the gas control

knob. See Lighting Instructions on the water heater.

4. Drain the water heater. Refer to the section of

“Draining and Flushing” section and follow the

procedure.

5. Disconnect the piezo igniter wire from the piezo igniter

button. NOTE: There are two types of igniters. If

you have the square igniter, slide the igniter bracket

backwards away from the gas valve to remove it. If

you have the round igniter, first remove the igniter

from the bracket by depressing front and rear holding

tabs and lift. Next remove igniter bracket from the

gas valve. Disconnect the thermocouple, pilot tube,

the two connectors attached to the thermal switch,

and manifold tube at the gas control valve/thermostat

(Figure 22). NOTE: L.P. gas systems use reverse (left-

hand) threads on the manifold tube.

6. Refer to “Gas Piping” section (Figure 3) and disconnect

the ground joint union in the gas piping. Disconnect the

remaining pipe from the gas control valve/thermostat.

7. To remove the gas control valve/thermostat, thread a

correctly sized pipe into the inlet and use it to turn the gas

control valve/thermostat (counterclockwise.) Do not use

pipe wrench or equivalent to grip body. Damage may

result, causing leaks.

Do not insert any sharp objects into the inlet or outlet

connections. Damage to the gas control valve/thermostat

may result.