Threading controls, Half nut lever, Power feed lever – Southbend SB1038F User Manual

Page 54: Thread dial & chart overview

-48-

For Machines Mfg. Since 7/09

EVS Toolroom Lathes

O P E R A T I O N

Note:

Take care not to misplace the key from the

gear shaft.

b.

Clean away debris and grime from the

gear and apply a light coat of machine

oil.

c.

Swap the position of the gear, as shown

in Figure 87, then align it with the key

and insert it on the gear shaft.

d.

Re-install the flat washer and cap screw.

Note:

DO NOT overtighten the cap screw. The

cap screw merely holds the gear in place

and overtightening it will make it harder to

remove later and may restrict its rotation.

4.

Close and secure the headstock side cover.

Half Nut Lever

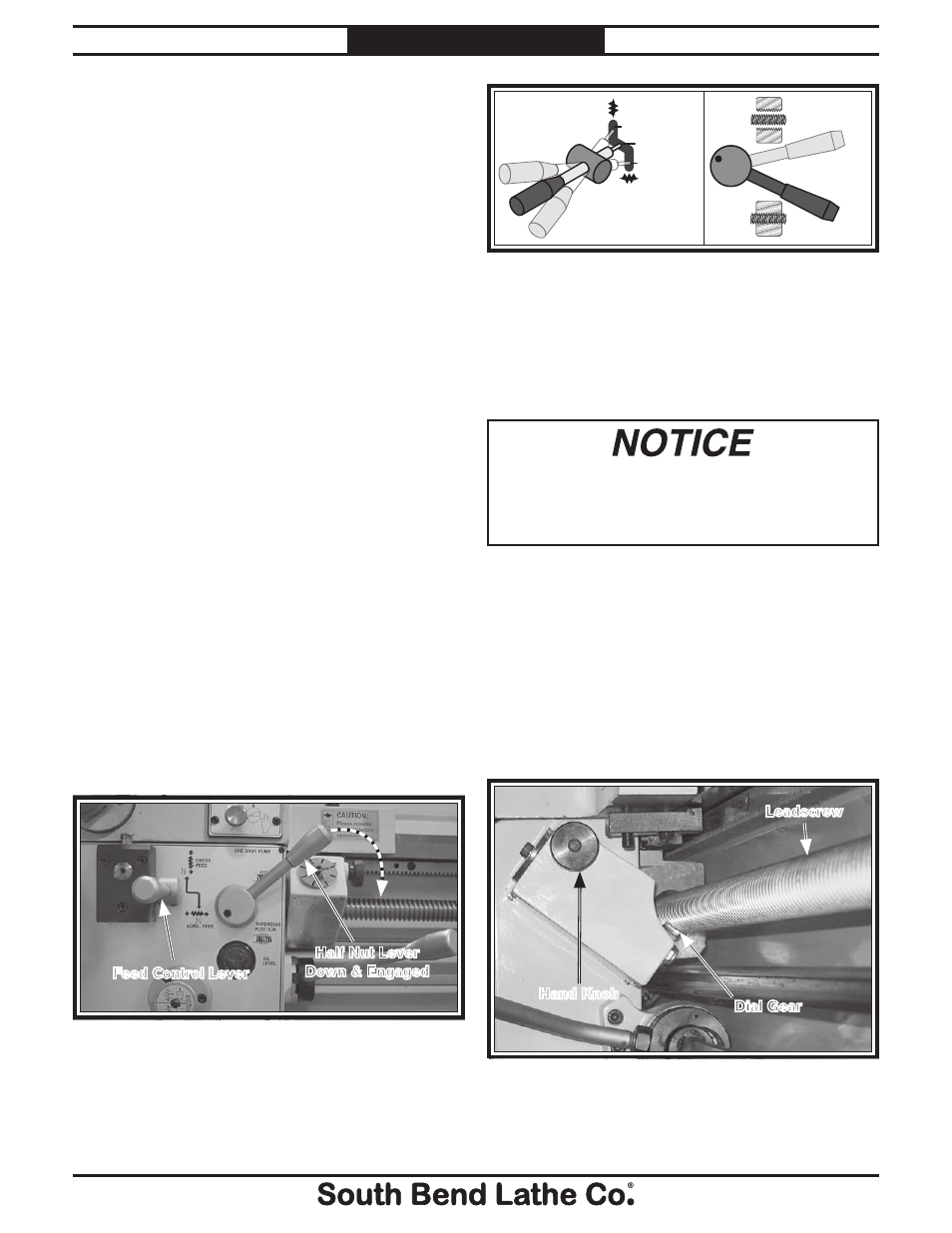

The half nut lever engages the carriage with the

leadscrew which moves the cutting tool along the

length of the workpiece (see Figure 89).

When threading, we recommend using the

slowest speed possible and avoiding deep

cuts, so you are able to disengage the half nut

and prevent an apron crash!

Figure 90. Feed control lever and half nut positions

for threading.

Threading Controls

If you are unfamiliar with how to cut threads on

a lathe, we strongly recommend that you read

books, review industry trade magazines, or get

formal training before beginning any attempting

any threading projects.

Power Feed Lever

The feed control lever must be in the neutral

(horizontal) position for threading operations or

the half nut will not engage with the leadscrew

(see Figures 89–90).

Figure 89. Carriage controls set up for threading.

Half Nut Lever

Down & Engaged

Feed Control Lever

Thread Dial & Chart Overview

The numbers on the thread dial are used with

the thread dial chart to show when to engage the

half nut during inch threading. The thread dial

gear must be engaged with the leadscrew for this

to work. Loosen the knurled hand knob on the

thread dial, pivot the dial gear into mesh with

the leadscrew, then tighten the hand knob (see

Figure 91).

Figure 91. Thread dial engaged with the leadscrew.

Leadscrew

Hand Knob

Dial Gear

Engaged

Disengaged

Cross Slide

Neutral

FEED CONTROL

LEVER

Carriage