Flight machine – Jackson JFT User Manual

Page 8

HOW TO SPECIFY - JFT:

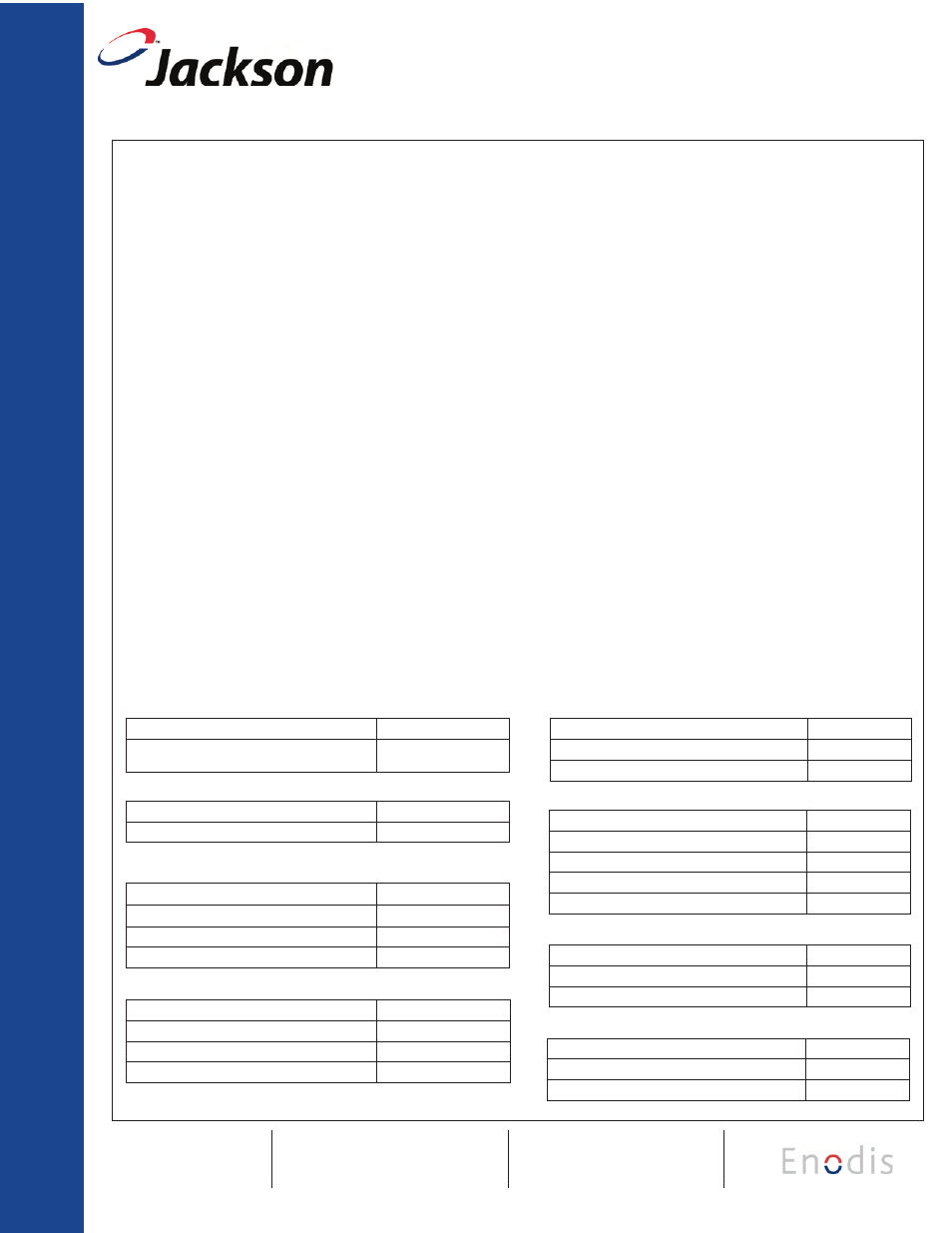

DIMENSION REQUIREMENTS

Wall Clearance (Minimum)

3” / (19 mm)

Inside Clearance

25”H x 30”W

(635 mm x 762 mm)

OPERATING CAPACITY

Dishes per Hour - Belt Speed 6.4 FPM

12,726

Dishes per Hour - Belt Speed 8.6 FPM

17,101

STEAM REQUIREMENTS

Steam Flow Pressure (PSIG)

15-30

Consumption @ 110˚F Incoming Water Temperature

145 lbs./hr.

Consumption with blower dryer

245 lbs.hr.

MOTORS

Pre-wash Pump Motor

3.0 HP

Wash Pump Motor

3.0 HP

Power Rinse Pump Motor

2.0 HP

Conveyor Drive Motor

1/4 HP

ELECTRICAL

An electromechanical control system for increased reliability mounted in a stainless steel control cabinet on the front of the machine.

A step-down transformer is included to provide 115 volt, 60 cycles, 1 phase operation for controls including selenoid valves, timers,

etc. Wiring is 105 C, 600-volt thermoplastic insulated wire and routed throught UL approved conduit.

Low watt density tubular heating elements are mounted inside the wash and power rinse tanks and are easily removable from the

exterior of the unit. Heaters are protected by a water level float switch control and a high limit overload.

Tank water temperature is maintained by a fast reacting thermostat which will control the heating element.

STEAM

Stainless steel tubular steam coils mounted inside the wash and power rinse tanks below the optimum water level and protected by

a water level float switch control. An external “Y” strainer and high temperature steam solenoid to regulate the flow of steam through

the coil. Tank temperature is controlled and maintained by a fast reacting thermostat that will control the operation of the steam

solenoid. A float and thermostatic steam trap to remove the condensate from the coil are included. Steam coils will require a 15-30

PSI flowing steam pressure.

Flight Machine

Highway 25E

P. O. Box 1060

Barbourville, KY 40906

Tel: 606-523-9795

Tel: 1-888-800-5672

Fax: 606-523-9196

E-mail: [email protected]

www.jacksonmsc.com

07610-002-85-11 (8/07)

We reserve the right to change specifications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

OPERATING TEMPERATURES

Pre-Wash (Recommended)

140˚F / (60˚C)

Wash (Minimum)

152˚F / (67˚C)

Rinse (Minimum)

161˚F / (72˚C)

Final Rinse

180˚F / (82˚C)

BOOSTER HEATERS - ELECTRIC

An internally mounted 27 kW electric booster heater sized to raise incoming 110˚F (43˚C) water supply to 180˚F (82˚C) minimum

for sanitizing rinse. The electric booster heater will have the capacity to heat 155 GPH from 110˚F (43˚C) to 180˚F (82˚C) minimum.

The tank is designed for a working pressure 150 PSI and hydrostatically tested at 300 PSI. The heater is complete with all plumbing,

including NPT pipe and fittings from inlet and outlet. Electric heating elements are metal sheathed controlled by a close tolerance

immersion thermostat. The booster is protected with a high temperature limit switch and low water cut-off.

BOOSTER HEATERS - STEAM

An internally mounted steam booster heater sized to raise incoming 110˚F (43˚C) water supply to 180˚F (82˚C) minimum for sanitiz-

ing rinse. The steam booster heater will have the capacity to heat 216 GPH from 110˚F (43˚C) to 180˚F (82˚C) minimum. The tank is

designed for a working pressure 150 PSI and hydrostatically tested at 300 PSI. The heater is complete with all plumbing, including

NPT pipe and fittings necessary to meet all installation requirements. The booster is protected with a high temperature limit switch

and low water cut-off.

PUMP CAPACITY

Pre-wash Pump

260 gal / (984 ltr)

Wash Pump

260 gal / (984 ltr)

Power Rinse Pump

230 gal / (871 ltr)

WATER REQUIREMENTS

Inlet Tempterature

110˚F / (43˚C)

Gallons per Hour

140 / (530 Ltr)

Waterline Size IPS (Minimum-inches)

3/4 / (19 mm)

Drainline Size IPS (Minimum-Inches)

2 / (51 mm)

Flow Pressure (PSI)

15-25

TANK CAPACITY

Pre-wash Tank

36 gal / (136 ltr)

Wash Tank

36 gal / (136 ltr)

Power Rinse Tank

36 gal / (136 ltr)