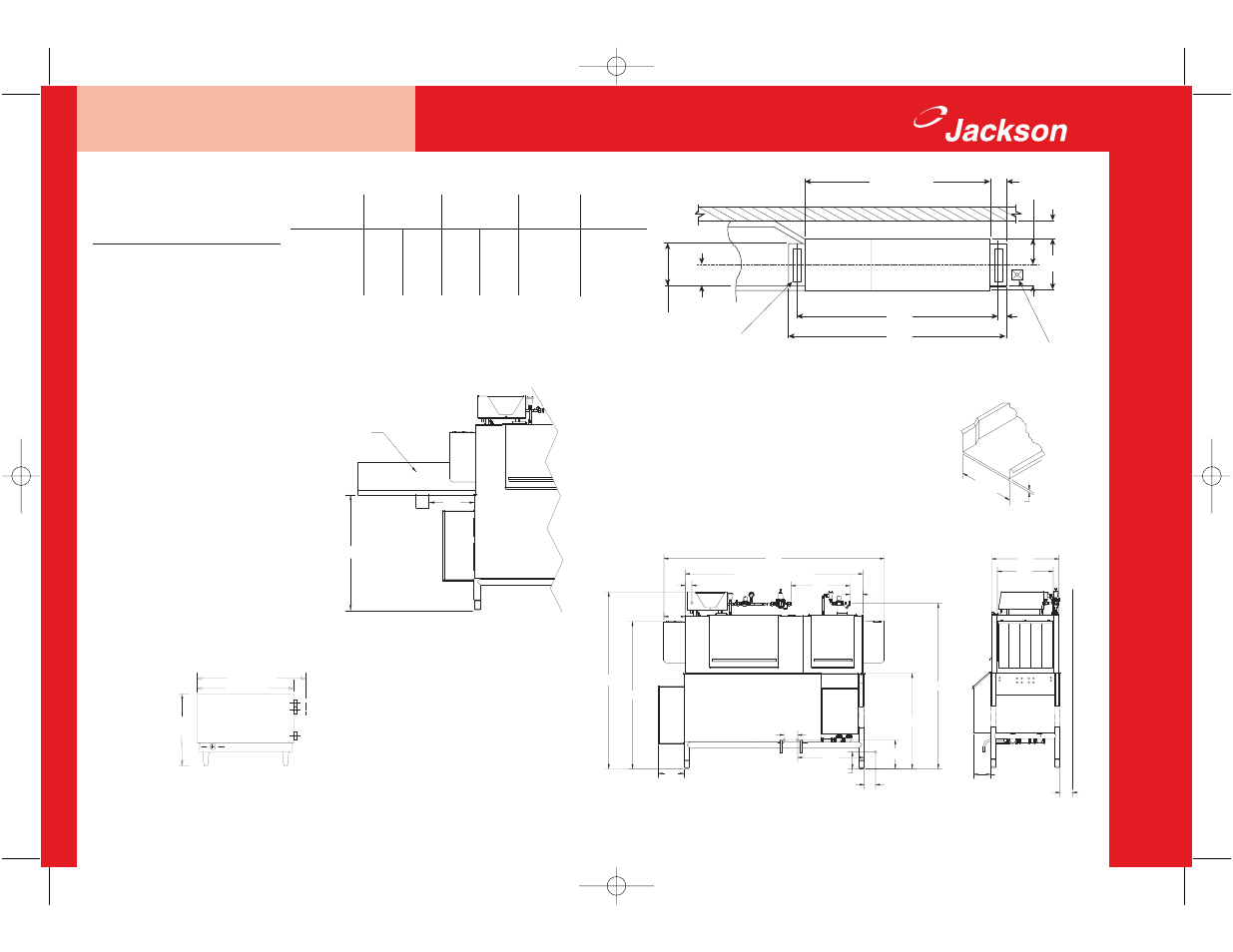

Ts-66 traditional series, Right to left operation shown – Jackson Conveyor Dishmachines TS-66 User Manual

Page 6

TS-66 Traditional

Series

Right to Left Operation Shown

07610-002-97-65A 8/04

All specifications subject to change without notice.

Recommended Table Fabrication

66”

TABLE TO TABLE

8”

12-1/2”

4”

74”

82”

4”

Floor sink or drain with

3” minimum drain line.

26”

8”

10-1/2”

21”

OPENING

4” wide x 16” long cutout in vent

cowl/splash shield. Shipped with

cover plates.

1-PH

3-PH

1-PH

3-PH

*3-PH

208 Volts 60 Cycles

88.3

51.8

18.3

10.1

66.6

230 Volts 60 Cycles

81.5

47.8

18.3

10.1

60.2

460 Volts 60 Cycles

N/A

23.9

N/A

5.1

30.1

TS-66 Series

Electrical Data

Approximate Total Load Amps

Electric Tank Heat

Steam Tank Heat

Optional 24 KW

Models:

Models:

Electric

TS-66

TS-66S

Booster Heater

Optional 36 KW

Electric

Booster Heater

*3-PH

99.9

90.4

45.2

*

Option electric boosters come in 3 phase only.

Note:

Optional booster heater requires separate electrical connection. 24

KW and 36 KW booster heaters are designed to supply the dishmachine

with rinse water at the appropriate temperature. Models do NOT come

with booster heaters as standard equipment.

30-1/2”

24”

18”

The maximum recommended distance between any electric

booster heater and the dishmachine is 20 ft.

All specifications subject to change without notice.

25”

21”

5-3/4”

W

ALL

4”

61-1/4”

34”

11-

4-1/2”

6-1/2”

24”

10”

53”

66”

8”

3”

66” TABLE TO TABLE

82”

22”

5”

5”

20-1/2”

1”

10” high backsplash

14”

34”

Scrap trough location MUST be a

minimum of 14” from the tub,

regardless of which side the trough

is mounted on.

Scrap Trough Location

Machine height with doors open is 72”.

Drive

Motor

Cover

Legend to Drawing

A

– Machine water inlet 1/2” I.P.S., 180°F minimum, 61-

1/4” above finished floor

B

– Electrical connection , approximately 61-1/4” above

finished floor. See table for amperage requirements

C

– Drain connection-1 1/2” I.P.S.

D

– Prewash water inlet 1/2” I.P.S. 110°F - 140°F

*E

–Condensate return connection, 3/4” FPT (return to

boiler feeder or open drain)

*F

– Incoming low pressure steam connection, 3/4” FPT

(gate valve supplied)

*

Steam tank heat option only

Note:

All vertical dimensions are +/- 1/2” from floor due

to adjustable bullet feet

A

D

C

E

F

B

TS-66 Drawings Rev A.qxd 10/15/04 9:52 AM Page 2