John Deere 30 User Manual

Page 2

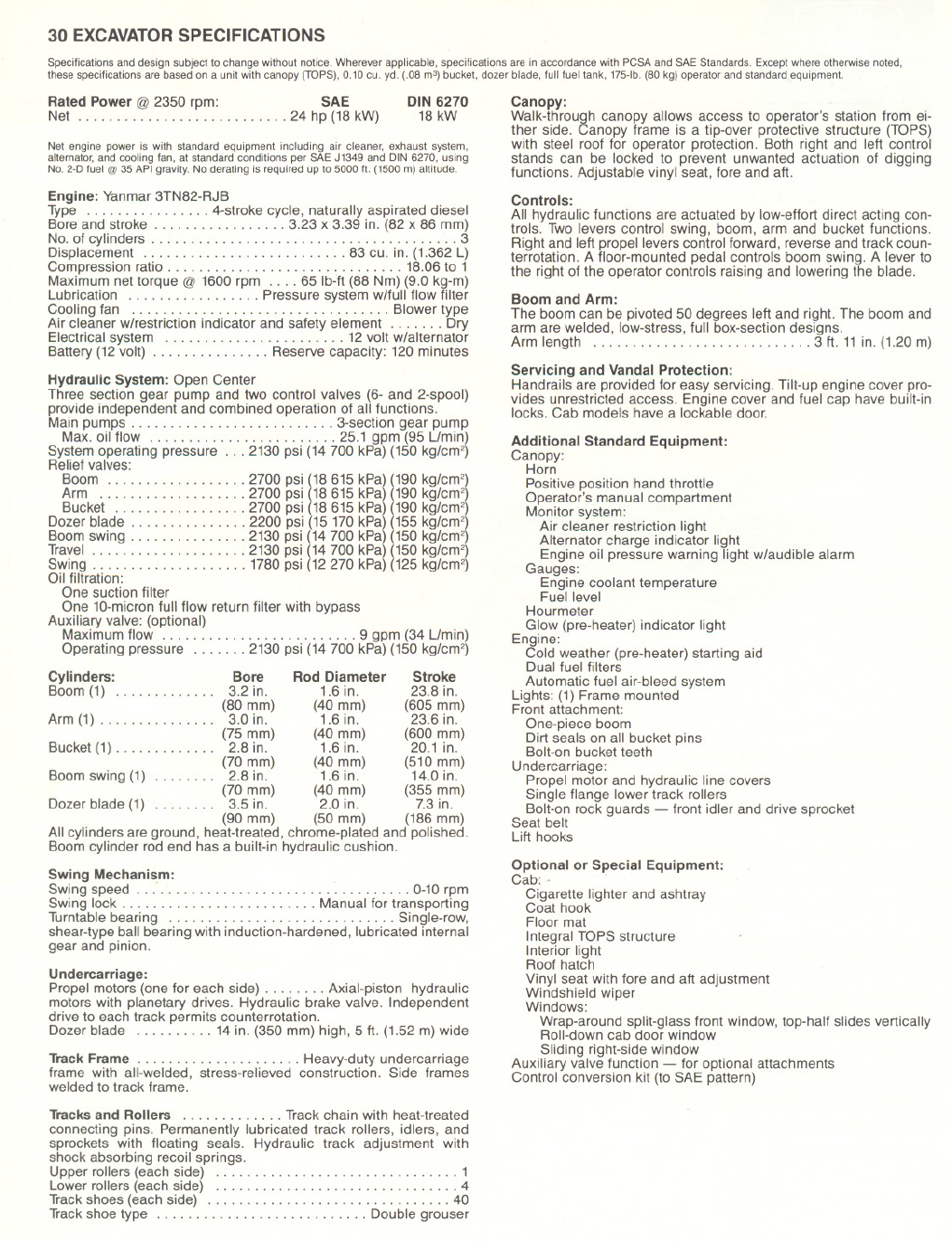

30 EXCAVATOR SPECIFICATIONS

Rated Power @ 2350 rpm:

SAE

Net

24hp(18kW)

DIN 6270

18 kW

Specifications and design subject to change without notice. Wherever applicable, specifications are in accordance with PCSA and SAE Standards. Except where otherwise noted,

these specifications are based on a unit with canopy (IDPS), 0.10 cu. yd. (.08 m3) bucket, dozer blade, full fuel tank, 175-lb. (80 kg) operator and standard equipment.

Net engine power is with standard equipment Including air cleaner, exhaust system,

alternator, and cooling fan, at standard conditions per SAE J1349 and DIN 6270, using

No. 2-D fuel @ 35 API gravity. No derating is required up to 5000 ft. (1500 m) altitude.

Engine: Yanmar 3TN82-RJB

Type. . . . . . . . . . . . . . . . 4-stroke cycle, naturally aspirated diesel

Bore and stroke

3.23x3.39in.(82x86mm)

No. of cylinders

3

Displacement

83cu.in.(1.362L)

Compressionratio

18.06t01

Maximum net torque @ 1600 rpm

65 Ib-ft (88 Nm) (9.0 kg-m)

Lubrication.

. . . . . . . . . . . . . . . . Pressure system w/full flow filter

Cooling fan

Blowertype

Air cleaner w/restriction indicator and safety element.

. . . . . . Dry

Electricalsystem

12voltw/allernator

Battery (12 voll) .. . . . . . . . . . . . . . Reserve capacity: 120 minutes

Hydraulic System: Open Center

Three section gear pump and two control valves (6- and 2-spool)

provide independent and combined operation of all functions.

Mainpumps

.3-section gear pump

Max. oil flow

25.1 gpm(95Umin)

System operating pressure. . . 2130 psi (14 700 kPa) (150 kg/em')

Relief valves:

Boom. . . . . . . . . . . . . . . . . . 2700 psi (18 615 kPa) (190 kg/em')

Arm

2700psi(18615kPa)(190kg/cm')

Bucket.

. . . . . . . . . . . . . . . . 2700 psi (18 615 kPa) (190 kg/em')

Dozer blade. . . . . . . . . . . . . . . 2200 psi (15 170 kPa) (155 kg/em')

Boom swing. . . . . . . . . . . . . . . 2130 psi (14 700 kPa) (150 kg/em')

Travel. . . . . . . . . . . . . . . . . . . . 2130 psi (14 700 kPa) (150 kg/em')

Swing

1780psi(12270kPa)(125kg/cm')

Oil filtration:

One suction filter

One 10-micron full flow return filter with bypass

Auxiliary valve: (optional)

Maximumflow

9gpm(34Umin)

Operating pressure.

. . . . . . 2130 psi (14 700kPa) (150 kg/em')

Cylinders:

Bore

Rod Diameter

Stroke

Boom (1)

3.2 in.

1.6in.

23.8 in.

(80 mm)

(40 mm)

(605 mm)

Arm(1)

3.0in.

1.6in.

23.6 in.

(75 mm)

(40 mm)

(600 mm)

Bucket(1)

2.8in.

1.6in.

20.1 in.

(70 mm)

(40 mm)

(510 mm)

Boom swing (1)

2.8 in.

1.6in.

14.0 in.

(70 mm)

(40 mm)

(355 mm)

Dozerblade(1)

""""

3.5 in.

2.0 in.

7.3 in.

(90 mm)

(50 mm)

(186 mm)

All cylinders are ground, heat-treated, chrome-plated and polished.

Boom cylinder rod end has a built-in hydraulic cushion.

Swing Mechanism:

Swing speed

0-10rpm

Swinglock

Manualfortransporting

Turntablebearing

Single-row,

shear-type ball bearing with induction-hardened, lubricated internal

gear and pinion.

Undercarriage:

Propel motors (one for each side) . . . . . . . . Axial-piston

hydraulic

motors with planetary

drives.

Hydraulic

brake valve. Independent

drive to each track permits counterrotation.

Dozer blade.

. . . . . . . . . 14 in. (350 mm) high, 5 ft. (1.52 m) wide

Track Frame.

. . . . . . . . . . . . . . . . . . . . Heavy-duty

undercarriage

frame

with all-welded,

stress-relieved

construction.

Side

frames

welded to track frame.

Tracksand Rollers.

. . . . . . . . . . . . Track chain with heat-treated

connecting pins. Permanently lubricated track rollers, idlers, and

sprockets with floating seals. Hydraulic track adjustment with

shock absorbing recoil springs.

Upper rollers (each side)

1

Lower rollers (each side)

4

Trackshoes(eachside)

40

Track shoe type

Doublegrouser

Canopy:

Walk-through canopy allows access to operator's station from ei-

ther side. Canopy frame is a tip-over protective structure (TOPS)

with steel roof for operator protection. Both right and left control

stands can be locked to prevent unwanted actuation of digging

functions. Adjustable vinyl seat, fore and aft.

Controls:

All hydraulic functions are actuated by low-effort direct acting con-

trols. Two levers control swing, boom, arm and bucket functions.

Right and left propel levers control forward, reverse and track coun-

terrotation. A floor-mounted pedal controls boom swing. A lever to

the right of the operator controls raising and lowering the blade.

Boom and Arm:

The boom can be pivoted 50 degrees left and right. The boom and

arm are welded,

low-stress,

full box-section

designs.

Armlength

3ft.11in.(1.20m)

Servicing

and Vandal Protection:

Handrails

are provided for easy servicing.

Tilt-up engine cover pro-

vides unrestricted

access.

Engine cover and fuel cap have built-in

locks. Cab models have a lockable door.

Additional

Standard

Equipment:

Canopy:

Horn

Positive position

hand throttle

Operator's

manual compartment

Monitor system:

Air cleaner

restriction

light

Alternator

charge indicator

light

Engine oil pressure warning

light w/audible

alarm

Gauges:

Engine coolant temperature

Fuel level

Hourmeter

Glow (pre-heater)

indicator

light

Engine:

Cold weather (pre-heater)

starting aid

Dual fuel filters

Automatic

fuel air-bleed

system

Lights: (1) Frame mounted

Front attachment:

One-piece

boom

Dirt seals on all bucket pins

Boll-on bucket teeth

Undercarriage:

Propel motor and hydraulic

line covers

Single flange lower track rollers

Boll-on rock guards -

front idler and drive sprocket

Seat belt

Lift hooks

Optional

or Special Equipment:

Cab:-

Cigarette

lighter and ashtray

Coat hook

Floor mat

Integral TOPS structure

Interior light

Roof hatch

Vinyl seat with fore and aft adjustment

Windshield

wiper

Windows:

Wrap-around

split-glass

front window, top-half slides vertically

Roll-down

cab door window

Sliding right-side

window

Auxiliary

valve function

-

for optional

attachments

Control conversion

kit (to SAE pattern)