General operation – Ice-O-Matic EMF Series User Manual

Page 14

Flake Ice Machines

General Information

Page

A12

General Operation

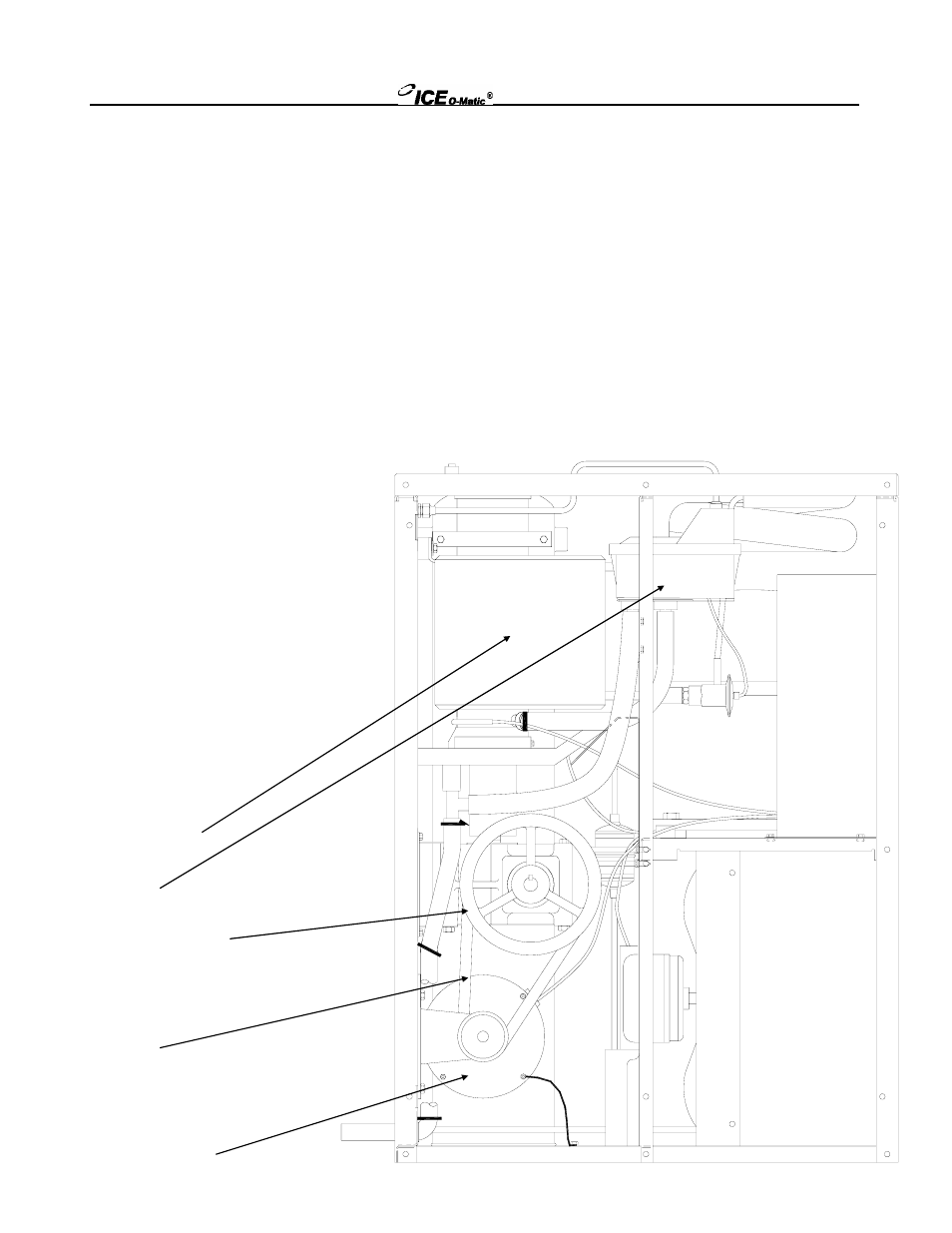

A general description of the flake ice machine operation is given below. The remainder of the

manual provides more detail about the components and systems.

Water enters a reservoir through the float valve and is gravity fed into the evaporator barrel

through an opening in the bottom of the barrel. Water fills the evaporator to the same level

as the water in the reservoir. A float valve, which stops the flow of water into the reservoir

when the reservoir becomes full, maintains this water level.

When the ON/OFF switch is turned on or when the bin control closes, the auger motor

energizes. The compressor is delayed for 2 to 4 minutes. After the compressor delay period,

the condenser fan motor (air cooled machines only) and compressor start and the

temperature of the evaporator barrel drops. The water in the evaporator freezes to the inner

walls of the evaporator

barrel.

A belt driven gear reducer

continuously turns the

auger inside the

evaporator. As the auger

turns, it pushes the ice

upward and forces it out of

the top of the barrel,

through the delivery chute,

and into the storage bin.

As ice is pushed out

through to top of the

evaporator, make-up

water enters the bottom of

the evaporator.

Evaporator

Gear Reducer

Float

V-Belt

Auger Motor