Drive system, Auger drive motor and v-belt – Ice-O-Matic EMF Series User Manual

Page 34

Flake Ice Machines

Drive System

Page

E1

Drive System

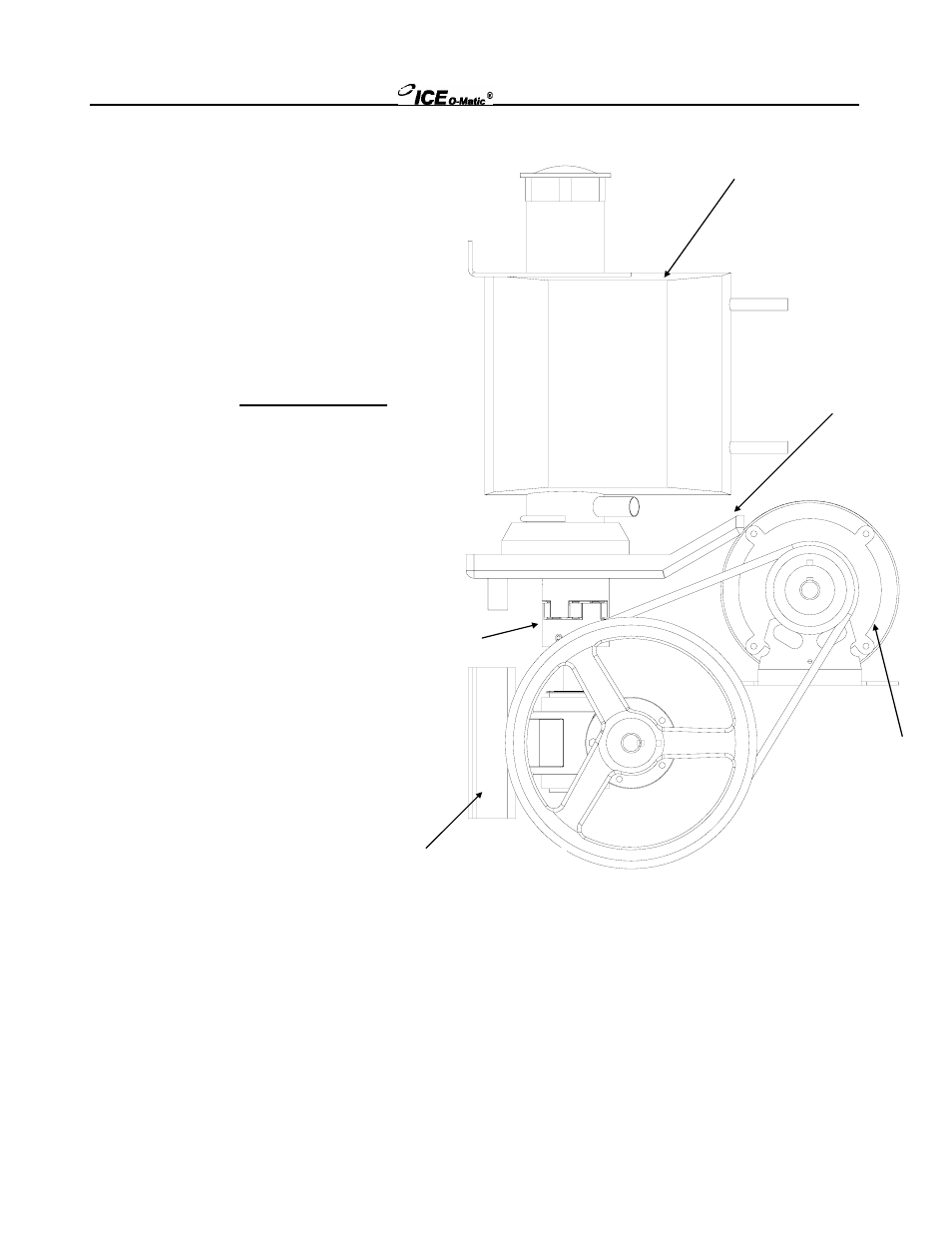

The drive system consists of all

components used to turn the auger.

The auger drive motor turns the gear

reducer via a V-Belt. A coupler is

used to connect the gear reducer to

the auger. The auger is located in

the evaporator and is supported by

two bearings, one at each end.

Auger Drive Motor and V-Belt

When facing the shaft, the auger

motor should turn counter clockwise.

A pulley on the shaft of the motor

holds one end of the V-Belt, which is

used to connect the auger motor to

the input shaft of the gear reducer.

The pulley on the auger drive motor

must be aligned with the pulley on

the input shaft of the gear reducer.

This can be checked by placing a

straight edge across the face of the

two pulleys. If out of alignment, the

pulleys can be repositioned by

loosening the setscrew that holds the

pulley to the shaft, realign the pulleys

and then retighten the setscrew.

The V-Belt can be adjusted by

loosening the four (4) auger motor

mounting bolts and moving the motor

until the proper belt tension is

achieved. The belt should be

adjusted so that it will flex

approximately ½ inch when applying

slight pressure to the center of the belt. If the V-Belt is too tight, it will put an excessive load

on the auger motor and gear reducer. If the V-Belt is too loose, it may slip and reduce ice

production.

Auger Motor

Coupler

Drip Boot

Gear Reducer

Evaporator

Auger motors should be oiled once a year with approximately 4 to 5 drops of SAE 20 oil in

each bearing.

Note: Models with two evaporators use a single drive motor with a shaft on each end of the

drive motor.