Vermont castings ewf36a – Majestic Appliances EWF36A User Manual

Page 23

23

Vermont Castings EWF36A

20005167

When to Suspect a Combustor Problem

The best way to evaluate the performance of your

EWF36A’s combustor is to observe the amount of smoke

leaving the chimney - both when the combustor has

“lighted-off” and when it has not. Follow these steps:

•

With a fire going and the combustor properly acti-

vated, with the damper closed to route smoke

through it as described in the Operation Section, go

outside and observe the smoke leaving the chimney.

•

Then, open the stove damper and once again check

the smoke leaving the chimney.

You should see significantly more smoke when the

stove damper is open and exhaust does not pass

through the combustor. However, be careful not to

confuse smoke with steam from wet wood. Steam

dissipates in the air quickly; smoke does not.

If this test indicates a problem, consider other possible

factors as well, such as the weather or a change in the

quality of your fuel. In warm weather, draft is weaker

than it is in colder winter weather and fires can burn

sluggishly. Small, hot fires are a good solution under

these conditions.

Burning “green” (insufficiently seasoned) wood will

result in poorer performance than burning properly

seasoned fuel. You may have to run your fireplace

hotter (more air) to achieve acceptable performance

using green or wet wood.

Also consider any changes in your operating routine.

Once you have ruled out any other possible causes for

a decline in performance, inspect and clean the com-

bustor if necessary.

Inspecting the Combustor

Use a flashlight and mirror, if necessary, to examine the

combustor. If no fly ash or damage is visible, the

inspection is complete. If closer examination, cleaning

or replacing is needed, go to the next section.

Removing, Cleaning or

Replacing the Combustor

1. Allow fireplace to cool.

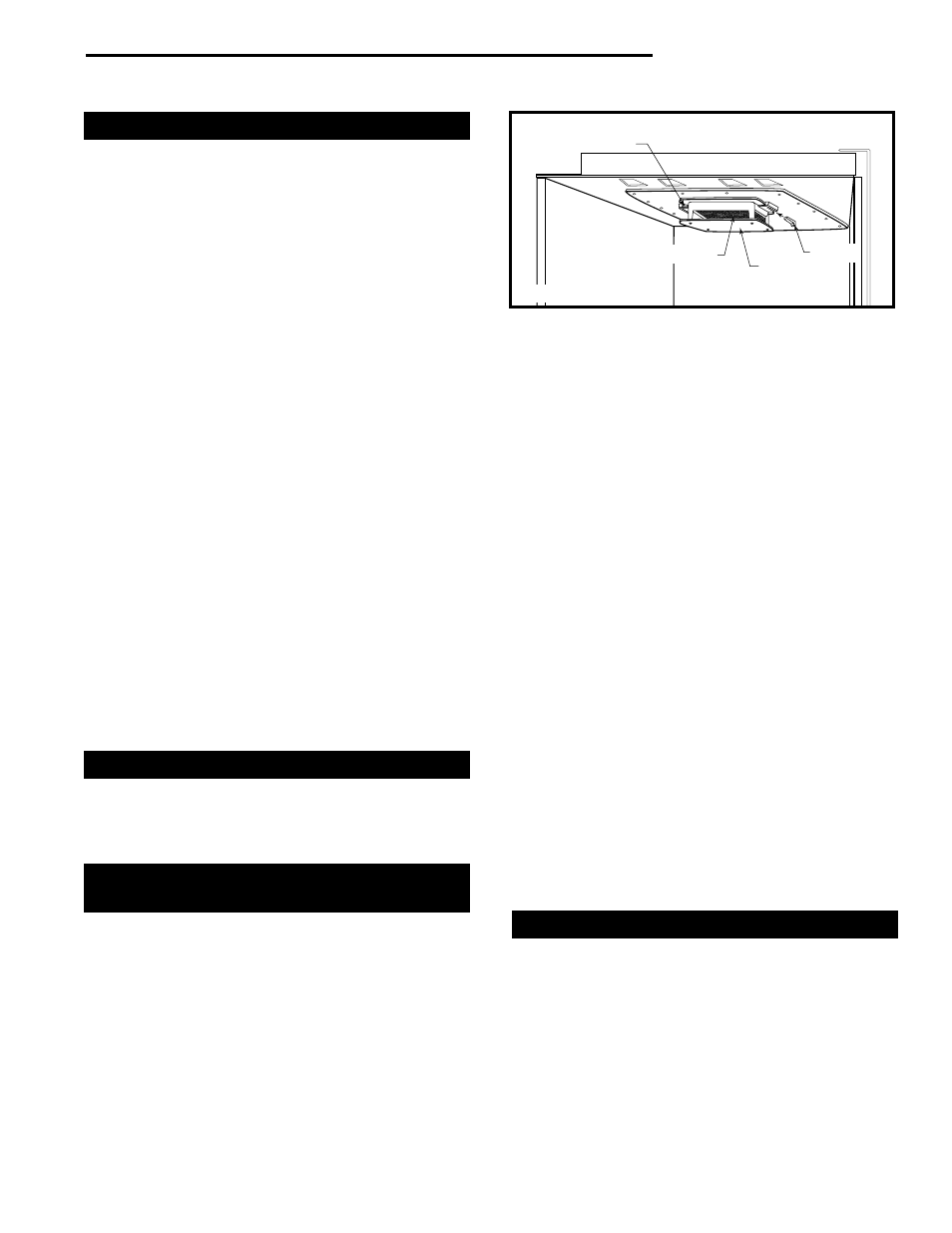

2. Tap the left and right wedges back and remove. (Fig.

31)

3. Carefully slide catalyst assembly to the back of the

fireplace and out of the retaining brackets.

4. Check the combustor’s honeycomb-like element for

a buildup of fly ash. If any is evident, take the

combustor outside and clean it by blowing air gently

through it. Do not push anything through the honey-

comb; do not use compressed air to clear the

Wedge (In Place)

Wedge

Catalyst

Catalyst

Assembly

FP1324

Fig. 31 Carefully tap out the wedges, then slide the Catalyst

Assembly out of fireplace.

passages. Such abrasion can scrape the thin

coating of platinum (the catalyst) off the ceramic

base, shortening the catalyst’s life and reducing its

effectiveness.

5. Inspect the element for damage or degradation.

Although small hairline cracks will not affect perfor-

mance, the element should be essentially intact. If

the element is broken in pieces or has sections

missing, it should be replaced. Call your local

Vermont Castings, Majestic Products authorized

dealer for a replacement element.

6. If the element is in good condition and clean,

reinstall it in the fireplace.

Operate the stove in your usual manner for two weeks,

inspecting the chimney and the chimney connector

frequently during this period.

If creosote does not build up as fast, it is likely that the

performance change was caused by fly ash deposits on

the catalytic element. However, continue the inspec-

tions of the chimney system for a few weeks to ensure

that proper performance continues.

If you continue to find a significant creosote buildup or if

you continue to see excessive smoke form the chimney,

the catalytic element will need to be replaced. Contact

your nearest Vermont Castings, Majestic Products

authorized dealer.

NOTE: Use only the replacement catalyst supplied by a

Vermont Castings, Majestic Products dealer.

How to Replace Gaskets

The EWF36A uses rope-type fiberglass gaskets to

make a tight seal between some parts. With use,

particularly on those parts that move, gaskets can

become brittle and compressed and can begin to lose

their effectiveness. These will need periodic replace-

ment.

All of the gaskets used are made of fiberglass. The

four sizes of replaceable gasket are listed below, along

with their application.