Miller Electric Millermatic 180 User Manual

Page 37

.

A complete Parts List is available on-line at www.MillerWelds.com

OM-225 311 Page 33

225 229-F

225 229−F

1.5/20

2/25

3.5/25

3/15

1/15

2.5/30

3.5/25

3.5/20

3/12

3.5/60

5/60

5.5/35

4/45

4/70

6/100

6/40

7/85

6/55

6/65

6.5/65

6.5/50

6.5/75

10/75

10/55

5.5/45

4.5/50

3.5/35

4.5/30

4.5/35

1.5/15

2/20

2/20

2.5/30

3.5/40 4.5/55

6/75

6/80

10/95

3/35

3.5/45

3.5/30

6/95

5/80

4.5/70

4/50

2/70

10/100

8/95

5/70

4/70

2/70

10/90

8/90

5/65

4/60

2.5/65

3.5/28

3.5/25

7.5/95

6/85

5/70

5/60

4/45

2.5/20

7.5/80

6/65

4.5/50

4/40

3.5/25

2/12

2/15

2.5/20

4.5/45

6/55

6.5/60 10/70

3.5/30

3/25

4/40

4/25

4/20

2/20

1/10

4/35

6/55

7/60

10/65

3/25

2/15

3/45

2/25

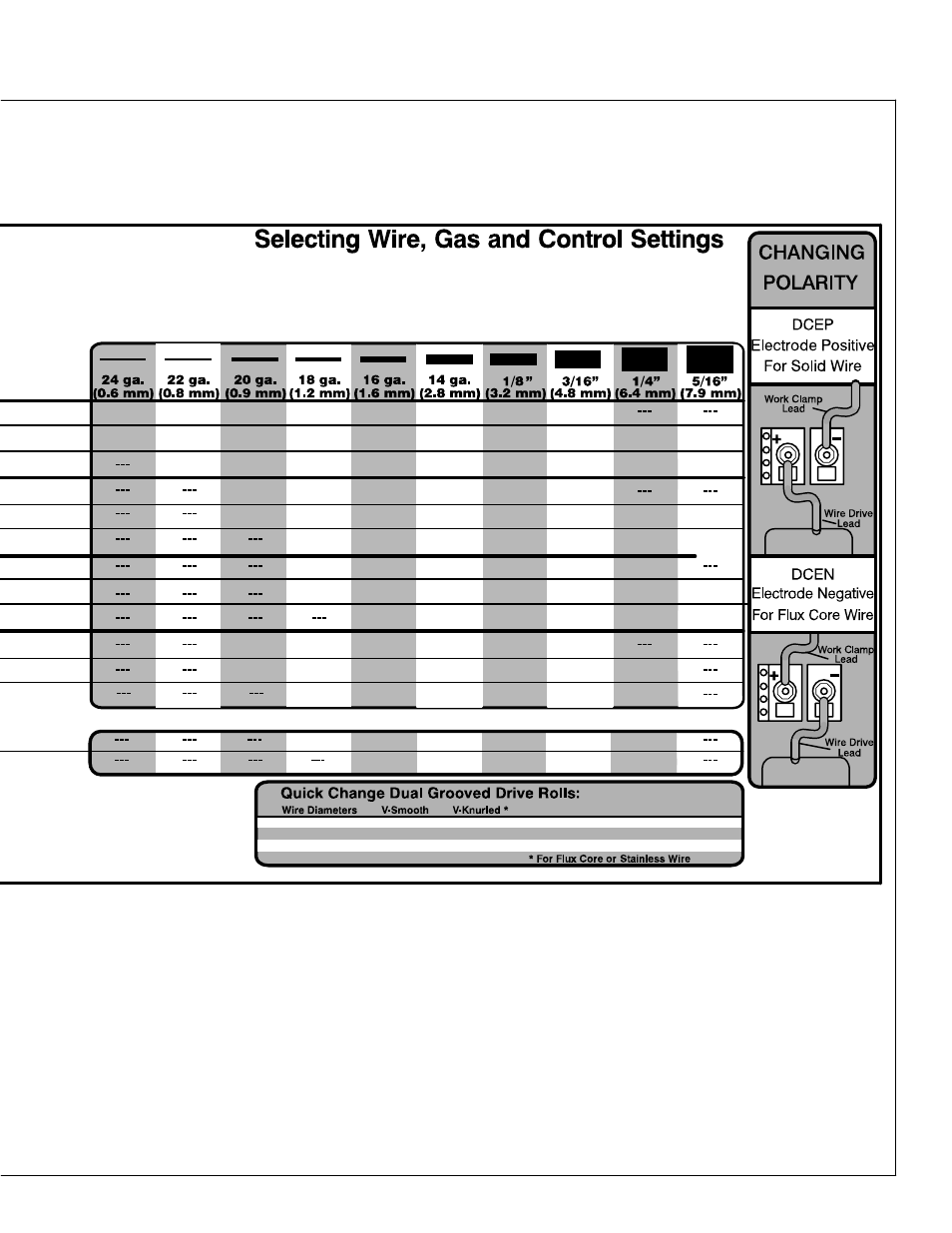

NOTE: Settings are approximate. Adjust as required.

“−−−” Means not recommended.

IMPORTANT: Match drive roll groove to diameter of wire being used. Set Tension

knob setting to 3 at start. Adjust tension per instructions in the manual.

.045” (1.2 mm) #202926

.024” (0.6 mm) #220179

.030” (0.8 mm) #220179 #202926

.035” (0.9 mm) #220179 #202926

4/25

6/35

7/40

10/45

3/15

2.5/10

Thicker materials can be welded using proper technique,

joint preparation and multiple passes.

with optional Spool Gun, Order part no. 300371