Work cable routing inside unit, Process/polarity table, Changing polarity – Miller Electric Millermatic 180 User Manual

Page 17: 3. work cable routing inside unit, 4. process/polarity table, 5. changing polarity

.

A complete Parts List is available on-line at www.MillerWelds.com

OM-225 311 Page 13

4-3.

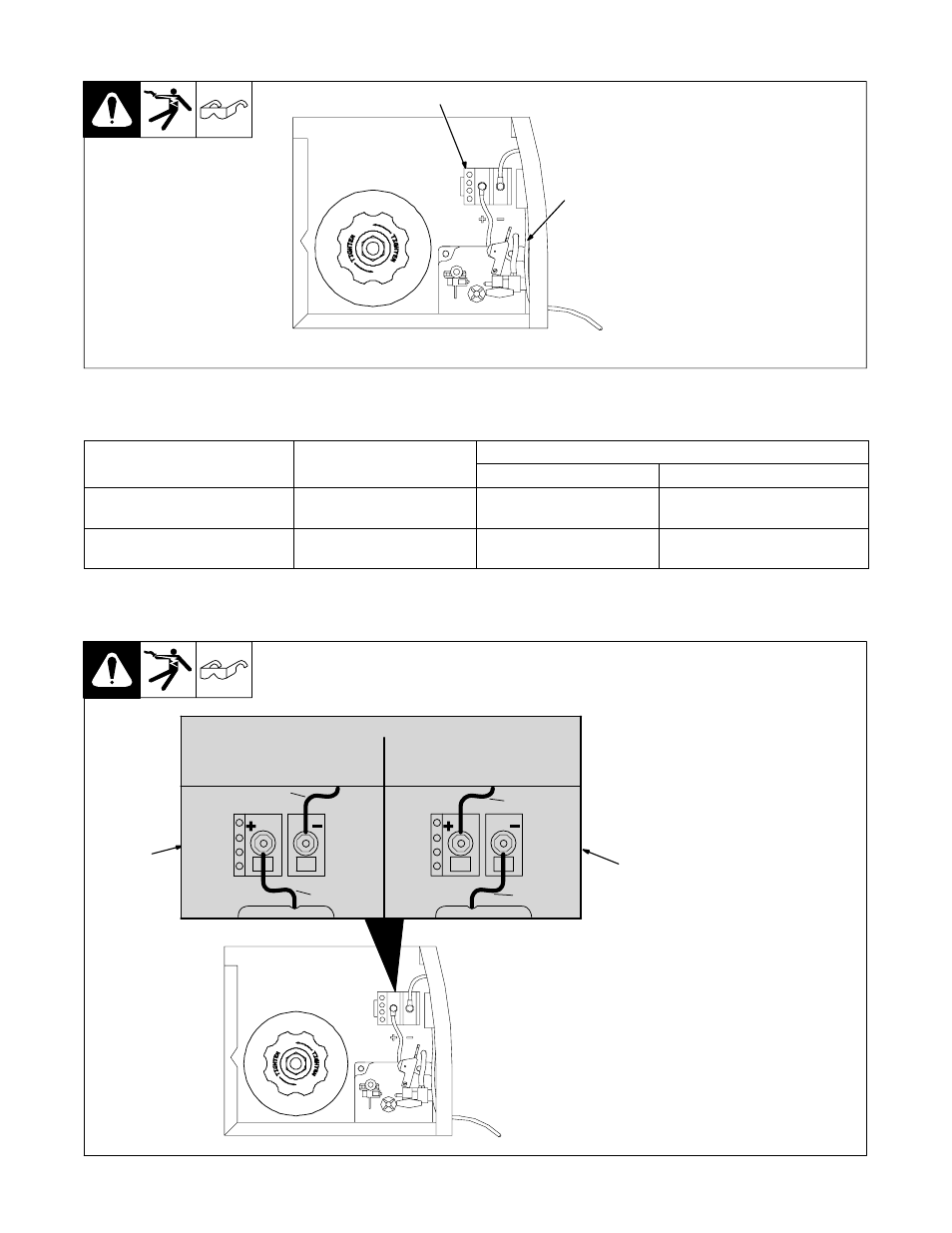

Work Cable Routing Inside Unit

Ref. 802 982-A

1

Work Cable

2

Output Terminal Block

Insert work cable through opening

in front panel and route along back

of front panel to output terminal

block.

Close door.

2

1

4-4.

Process/Polarity Table

Process

Polarity

Cable Connections

Process

Polarity

Cable To Gun

Cable To Work

GMAW − Solid wire with shield-

ing gas

DCEP − Reverse polarity

Connect to positive (+) out-

put terminal

Connect to negative (−) output

terminal

FCAW − Self-shielding wire −

no shielding gas

DCEN − Straight Polarity

Connect to negative (−)

output terminal

Connect to positive (+) output

terminal

4-5.

Changing Polarity

1

Lead Connections For Direct

Current Electrode Positive

(DCEP)

2

Lead Connections For Direct

Current Electrode Negative

(DCEN)

Always read and follow wire

manufacturer’s recommended

polarity, and see Section 4-4.

Close door.

1

Ref. 203 501 / Ref. 802 982-

2

C H A N G IN G P O L A R IT Y

DCEP

Electrode POSITIVE

FOR SOLID WIRE

DCEN

Electrode Negative

Flux Core Wire

WorkClamp

Lead

Wire Drive

Lead

WorkClamp

Lead

Wire Drive

Lead

C H A N G IN G P O L A R IT Y

DCEP

Electrode Positive

FOR SOLID WIRE

DCEN

Electrode Negative

Flux Core Wire

WorkClamp

Lead

Wire Drive

Lead

WorkClamp

Lead

Wire Drive

Lead

.

Connection hardware must be tightened with proper tools. Do not

just hand tighten hardware. A loose electrical connection will cause

poor weld performance and excessive heating at the terminal block.