MITSUBISHI ELECTRIC 882.00273.00 User Manual

Page 53

Because the blending systems must handle a wide variety of materials, with varying bulk

densities, the actual amount of weight of material the weigh hopper will hold can vary

dramatically from application to application.

This feature allows the operator to change the size of the batch to be made. A value will need

to be entered between 0.5 to 99.9. This can also be changed while making a batch without

affecting the current running batch. If the size is changed then you will need to touch

“Accept New Recipe” on the Recipe screen before the change takes place. This feature

allows stored recipes with different batch sizes to easily be loaded without the operator

having to reconfigure the blender every time they want to load a stored recipe.

The weigh hopper size selected should be one that approaches the maximum capacity of the

load cells without over-filling the weigh hopper. During the initial setup of each blender, the

weigh hopper size setting should be checked to ensure that the weigh hopper is not overfilling

due to a large percentage of light weight regrind, etc. The batch size will vary from model to

model. The bulk density of the material being blended will also affect the batch size.

Note: If running a high percentage of lighter density regrind, set the batch size

so that the mixer does not overfill, preventing the weigh hopper from

fully dumping when operating in “Batch Ready Mode”.

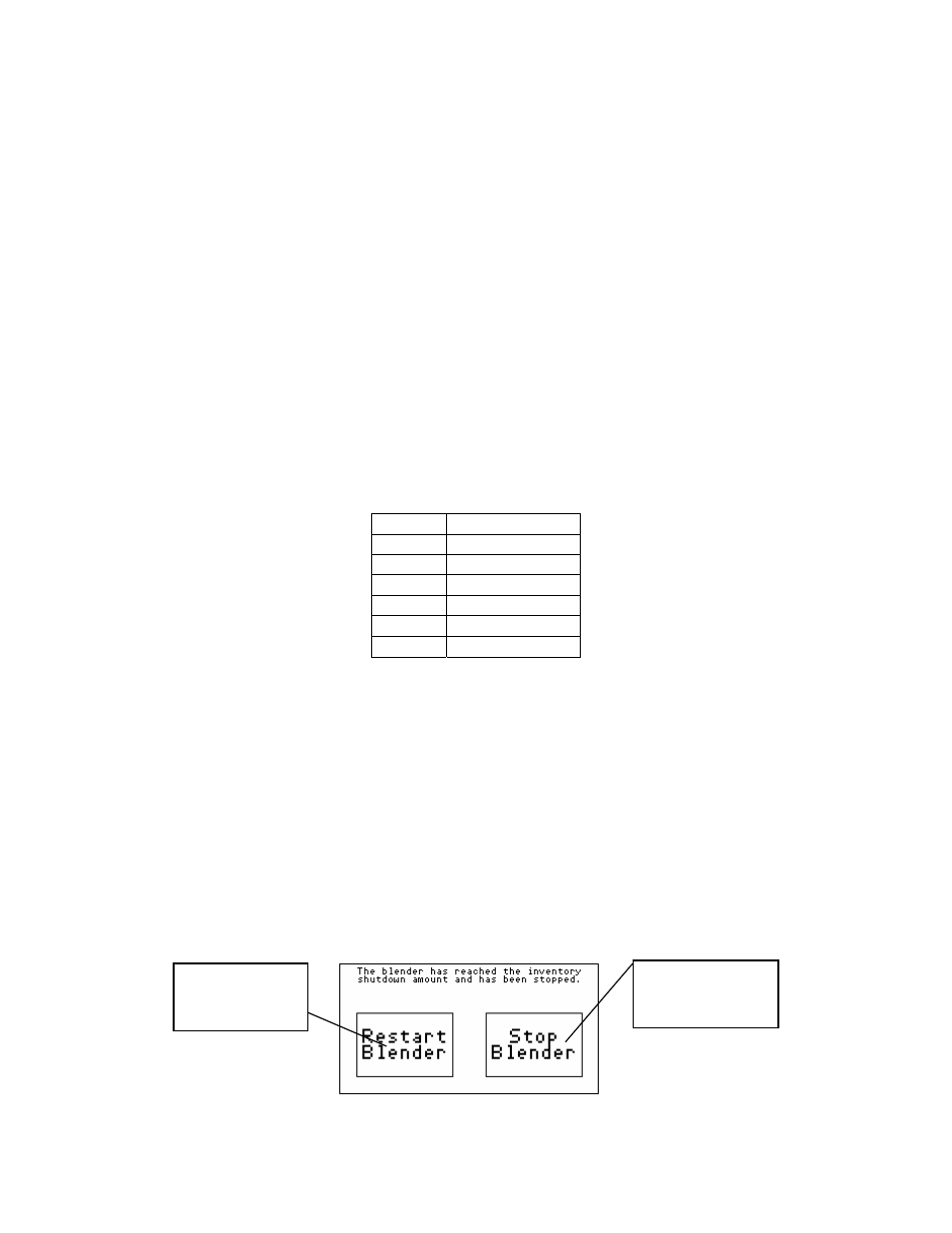

Figure 38: Typical Batch Sizes

Blender

Batch Size (lbs.)

150 1.5

500 4.0

900 8.0

2500 25.0

4000 35.0

6000 45.0

Inventory Shutdown

In many applications, the user of the Slide Gate/Auger System produces large runs of blended

material on the same recipe during production. An example may be a 40,000-lb. run of a

certain specification plastic extrusion. Others may wish to fill a 1,000-lb. gaylord box in a

central blending application. In either case, the manufacturer has provided a means to

automatically stop the blending system when the blended material has reached a preset total

blended weight. This is known as Inventory Shutdown.

When the Inventory Shutdown value is reached, the blender will finish the current batch of

material. It will then stop and display to the operator that the inventory value has been

reached. Additionally, it will flash an alarm and wait for operator attention. An example of

this screen is shown below:

Figure 39: Typical Blender Shutdown User Prompt Operator Screen

Touch if you don’t

want to make another

batch

Touch to make

another box of

material

BF1-615.3

Chapter 4: 3BOperation

53 of 101