0 installation, 5 installing the ductwork and registers – Maytag Ventilation Systems HRV-210 User Manual

Page 16

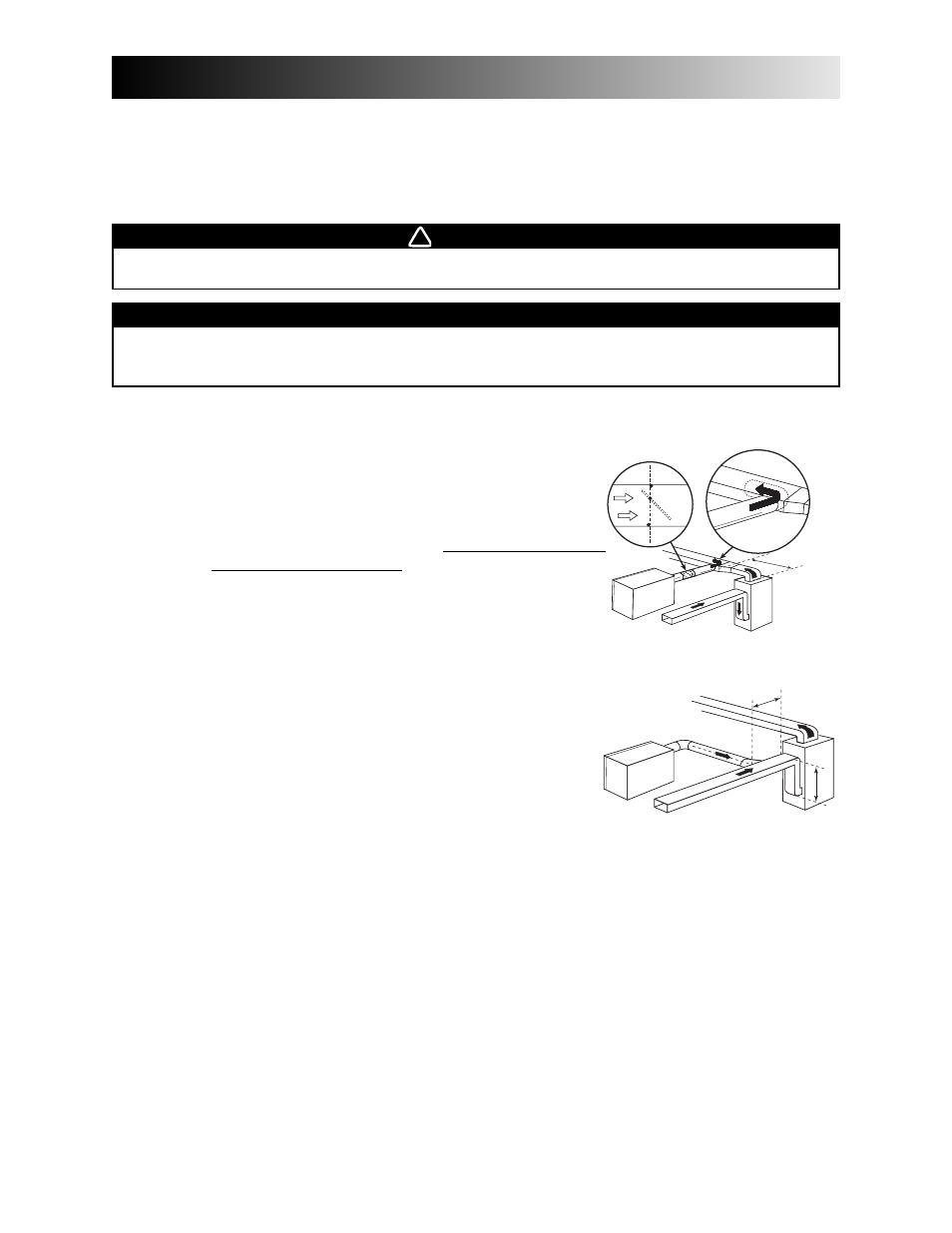

6.5.2 Exhaust Ducted System

(Source Point Ventilation) (as illustrated in Section 5.2)

Stale air exhaust ductwork:

(same as for Fully Ducted System, described on page 15)

Fresh air distribution:

There are two methods for connecting the unit to the furnace:

Method 1: supply side connection

• Cut an opening into the furnace supply duct at least

18 inches (0.5 m) from the furnace.

• Connect this opening to the fresh air distribution port

of the HRV/ERV (use steel duct, see figure 10).

• Make sure that the HRV/ERV duct forms an elbow

inside the furnace ductwork.

• If desired, interlock (synchronize) the furnace blower

operation with the HRV/ERV operation.

(See Section 8.4).

Method 2: return side connection

• Cut an opening into the furnace return duct not less than

10 feet (3.1 m) from the furnace (A+B).

• Connect this opening to the fresh air distribution port of

the HRV/ERV (see figure 11).

NOTE: For Method 2, it is not essential that the furnace

blower runs when the HRV/ERV is in operation,

but we recommend it. If desired, synchronize the

furnace blower operation (see Section 8.4).

16

6.0

Installation

(cont’d)

6.5 Installing the Ductwork and Registers

(cont’d)

VD0040

B

A

VD0041

minimum

18” (0.5 m)

Steel duct with

backdraft damper

A+B= not less

than 10’ (3.1 m)

figure 10

figure 11

WARNING

010

!

When performing duct connection to the furnace, installation must be done in accordance with all

applicable codes and standards. Please refer to your local building code.

CAUTION

When performing connection to the furnace supply duct, this duct must be sized to support the

additional airflow produced by the HRV/ERV. Also, use a steel duct with a backdraft damper to pre-

vent the risk of overheating the HRV/ERV.