5. shielding gas connection to regulator/flowmeter, 6. shielding gas connections to gas control – Miller Electric A.B.B. Robot Interface Gas Control Hub And Spindle User Manual

Page 15

OM-884 Page 11

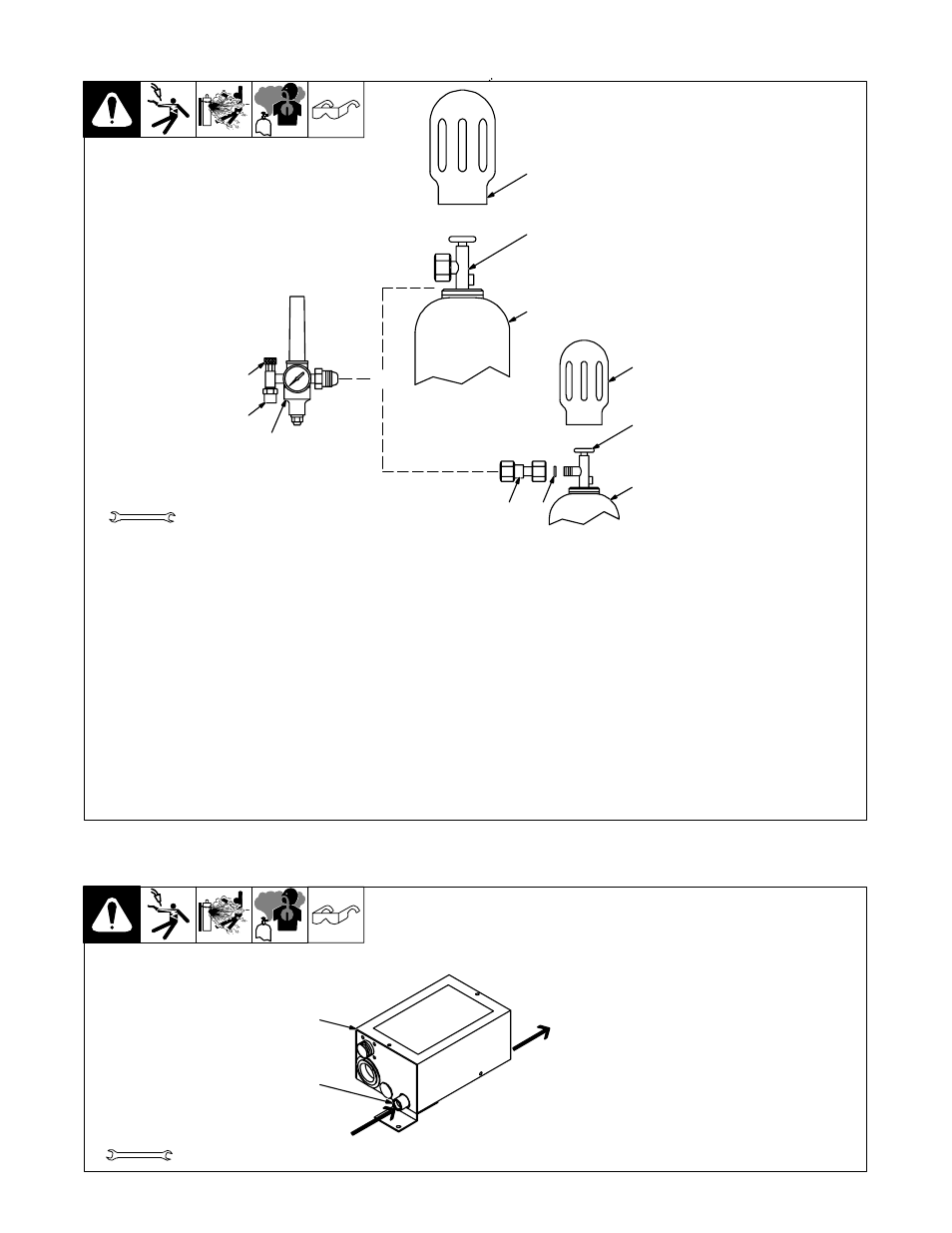

2-5.

Shielding Gas Connection To Regulator/Flowmeter

ssb3.1 5/94 – ST-158 697-A

Obtain gas cylinder and chain to running

gear, wall, or other stationary support so

cylinder cannot fall and break off valve.

1

Cap

2

Cylinder Valve

Remove cap, stand to side of valve, and

open valve slightly. Gas flow blows dust

and dirt from valve. Close valve.

3

Cylinder

4

Regulator/Flowmeter

Install so face is vertical.

5

Gas Hose Connection

Fitting has 5/8-18 right-hand threads. Ob-

tain and install gas hose.

6

Flow Adjust

Typical flow rate is 20 cfh (cubic feet per

hour). Check wire manufacturer’s

recommended flow rate.

Make sure flow adjust is closed when

opening cylinder to avoid damage to the

flowmeter.

7

CO

2

Adapter

8

O-Ring

Install adapter with O-ring between

regulator/flowmeter and CO

2

cylinder.

Obtain gas cylinder and chain to running

gear, wall, or other stationary support so

cylinder cannot fall and break off valve.

Tools Needed:

1-1/8, 5/8 in

CO

2

Gas

7

8

3

1

2

4

5

6

1

2

3

Argon Gas

OR

2-6.

Shielding Gas Connections To Gas Control

ST-080 485-A

1

Gas Control

2

Shielding Gas Valve Fitting

Tools Needed:

5/8 in

From Regulator/

Flowmeter

To Gun

1

2