Troubleshooting, Motor & electrical, Wood lathe operation – Grizzly G0624 User Manual

Page 26

-24-

G0624 10" Benchtop Lathe

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel-

ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical

Support at (570) 546-9663.

SECTION 7: SERVICE

Troubleshooting

Motor & Electrical

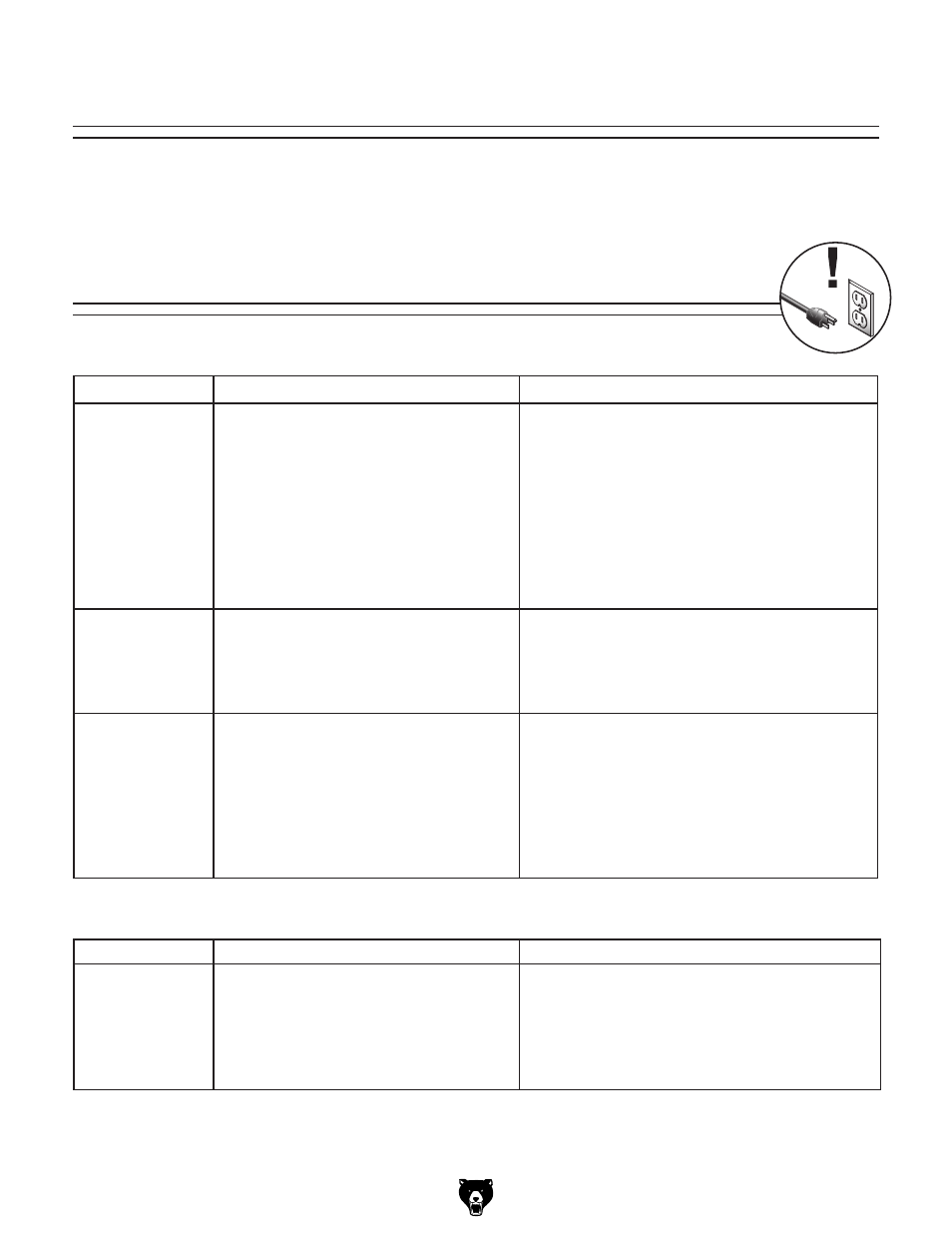

Symptom

Possible Cause

Possible Solution

Machine does not

start or a breaker

trips.

1. Plug/receptacle is at fault or wired incor-

rectly.

2. Power supply is at fault/switched OFF.

3. Lockout key is at fault.

4. Motor ON button or ON/OFF switch is at

fault.

5. Wiring is open/has high resistance.

6. Motor is at fault.

1. Test for good contacts; correct the wiring.

2. Ensure hot lines have correct voltage on all legs and

main power supply is switched ON.

3. Install/replace lockout key; replace switch.

4. Replace faulty ON button or ON/OFF switch.

5. Check for broken wires or disconnected/corroded

connections, and repair/replace as necessary.

6. Test/repair/replace.

Machine stalls or is

underpowered.

1. Plug/receptacle is at fault.

2. Motor bearings are at fault.

3. Motor has overheated.

4. Motor is at fault.

1. Test for good contacts; correct the wiring.

2. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

3. Clean off motor, let cool, and reduce workload.

4. Test/repair/replace.

Machine has vibra-

tion or noisy opera-

tion.

1. Motor or component is loose.

2. Motor fan is rubbing on fan cover.

3. Workpiece or chuck is at fault.

4. Motor bearings are at fault.

1. Inspect/replace stripped or damaged bolts/nuts, and

re-tighten with thread locking fluid.

2. Replace dented fan cover; replace loose/damaged

fan.

3. Center workpiece in chuck or face plate; reduce

RPM; replace defective chuck.

4. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Vibration noise

while machine

is running; noise

changes when

speed is changed.

1. Belt cover loose.

2. Belt cover bent or dented and is making

contact with the motor pulley or belt.

1. Tighten the belt cover lock handle; if necessary

install a soft, vibration dampening material (between

the belt cover and the headstock casting.

2. Remove belt cover and inspect the inside for dents,

bends, or indications of rubbing. Tap out the dent

with a rubber mallet, bend back into proper shape,

or shim belt cover away from the motor pulley.

Wood Lathe Operation