Troubleshooting guide – Grindmaster CRATHCO HC-2 User Manual

Page 9

Crathco

®

Whipped Hot Chocolate Dispensers

Page 6

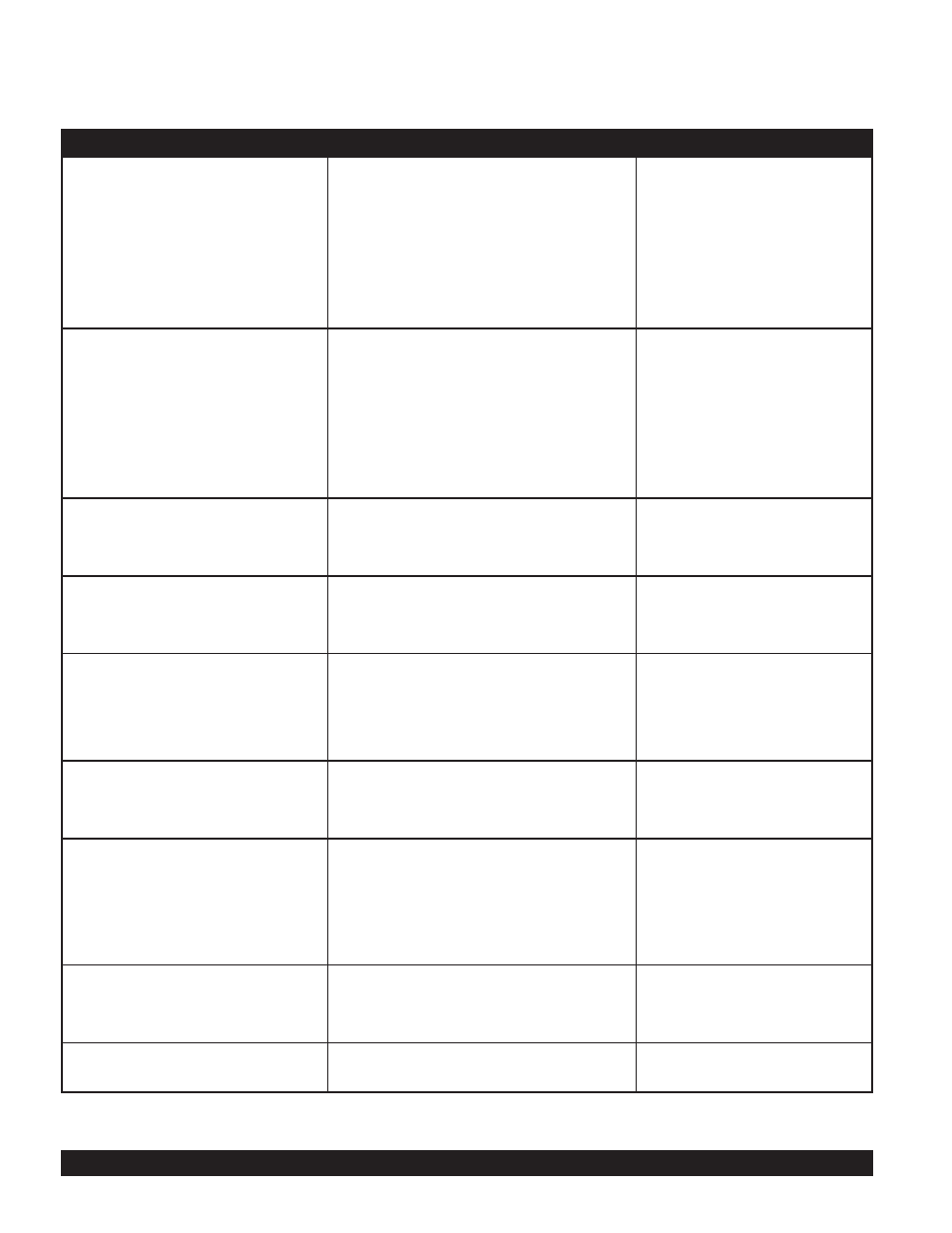

Troubleshooting Guide

The following procedures must be performed by a qualified service technician.

Problem/Possible Cause

Service Check

Remedy

Consistent filling of water tank

•

•

•

•

Water not heating up

•

•

•

•

Nothing dispensed - water or

chocolate - No whipper action

•

No water dispensed or whipper

action - Only chocolate is dispensed

•

No water dispensed - Whipper

works and chocolate is dispensed

•

•

•

No whipper action - only water

and chocolate are dispensed

•

No chocolate dispensed - Whipper

works and some water is

dispensed

•

•

•

Constant dispense - chocolate,

water and whipper action

•

Constant water dispense or drip

•

Leaking fill solenoid valve

Electrode lined up or faulty

Faulty white common

connection to ground

Liquid level control faulty

Thermostat Off

Thermostat faulty

Power relay faulty

Heating element faulty

Dispense switch faulty

Water switch faulty

Tank refill problem

Kinked silicone tubing

Dispense valve faulty

Whipper motor faulty

No syrup to pump

Kinked pump tubing

Syrup pump faulty

Dispense switch faulty

Dispense valve faulty

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Removing power to machine does not

stop tank fill

Jumper from C to high on probe side of

board shuts fill off

Jumper from COM on probe side of

board to ground stops fill

Jumper from High to COM on probe

side of liquid level does not shut fill Off

Visual

Thermostat contacts do not close with

sleeve clockwise and inner screw

counter clockwise

No voltage to heating element - 120V.

across coil of relay does not pull in

120V across heating element but no

heat-element reads open with ohmeter

Switch reads open with ohmeter when

switch is pushed

Switch reads open with ohmeter when

switch is in On position

Check auto refill system

Check tubing run to mixer assembly

120V across input terminals on valve-

no actuation

120V across motor leads but motor

does not run

Check syrup container

Check tubing runs

120V across pump motor leads, pump

does not run; check for jammed rollers

Switch reads closed with ohmeter with

switch in the Off position

Dispense or drip continues with

power Off

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Clean-replace fill valve

Clean electrode rods. Check

rods & wiring; replace if

necessary

Tighten, clean, replace COM

connection to ground

Replace liquid level control

Turn thermostat sleeve clockwise

Replace thermostat

Replace power relay

Replace heating element

Replace switch

Replace switch

Clean-replace components

Reroute tubing-unkink

Replace coil or entire valve

Replace whipper motor

Replenish syrup supply

Unkink, reroute, replace

Replace syrup pump-Unjam

rollers

Replace switch

Clean, rebuild; replace

dispense valve