Global Machinery Company LS1620 User Manual

Page 9

9

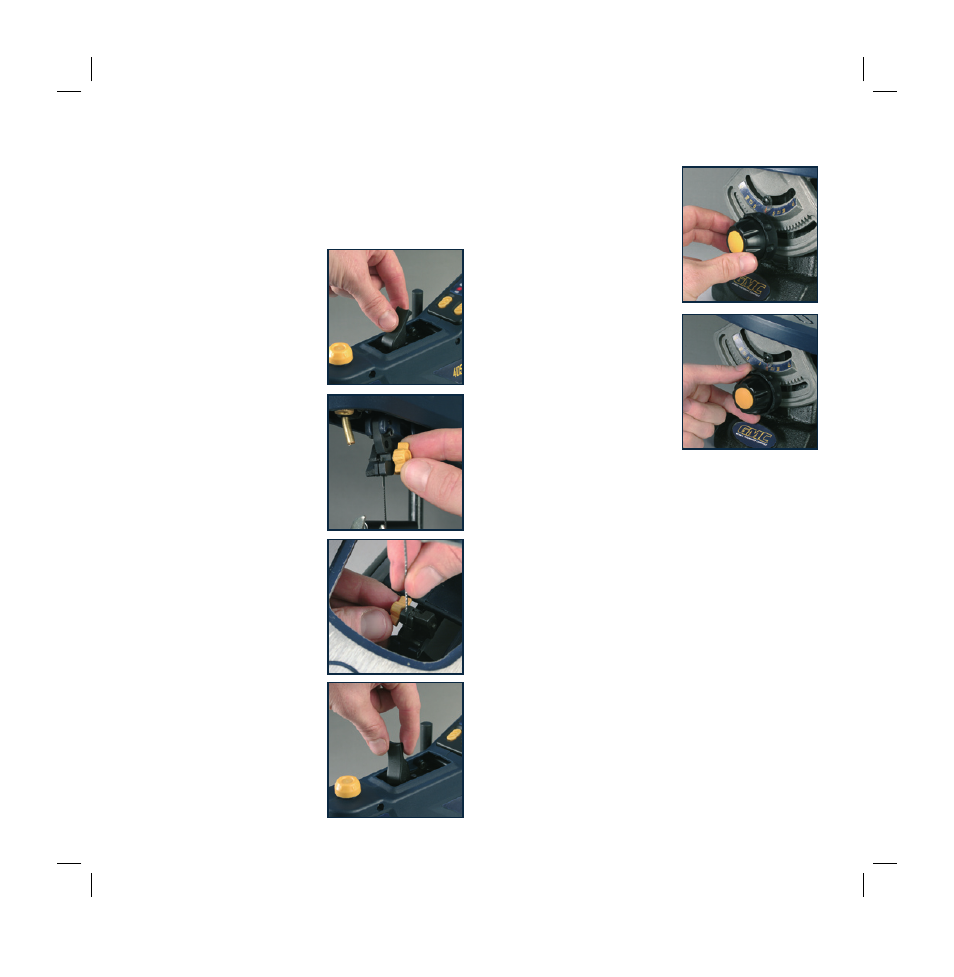

Installing blades

CAUTION.

Always ensure that the saw is switched

off and unplugged from the mains supply before

removing or installing a blade.

1. Lift up the blade tension lever (12) to reduce the blade tension.

2. Remove the table insert (11)

by raising it with a screwdriver.

3. Loosen the upper and lower

blade adapter knobs (14).

Ensure that the slots on

the upper and lower blade

adapters are wider than the

thickness of the blade.

4. In order to cut effectively and

avoid uncontrollable lifting of

the workpiece, the teeth of the

scroll saw blade must always

point in a downward direction.

5. Insert the blade in the lower

blade adapter and tighten the

blade adapter knob.

6. Press the upper arm down

and insert the top part into

the upper blade adapter and

tighten the blade adapter knob.

7. Lower the blade tension lever

to secure the blade in position.

8. If the tension is too tight when

lowered, lift the blade tension

lever back up and turn it in

an anti-clockwise direction to

loosen the blade tension.

9. If the tension is too loose

when lowered, lift the blade

tension lever back up and turn

it in a clockwise direction to

tighten the blade tension.

10. Replace the table insert.

Setting the table for horizontal

or bevel cutting

CAUTION.

Always ensure that

the saw is switched off and

unplugged from the mains supply

before making any adjustments.

1. Loosen the table lock knob

(17) to allow the saw table to

be tilted to the left and right.

The table can be locked at

any angle from a 0º horizontal

cutting position up to a 45º

angle both to the left and right

for bevel cutting.

2. Rotate the table adjustment

knob (18) to move the table from

left to right. Rotate the knob in a

clockwise direction to move the

table to the left and an anti-clockwise direction to move

the table to the right.

3. A bevel adjustment scale (16) is positioned under the

work table to assist in setting the appropriate table angle

for bevel cutting. When greater precision is required,

make a practice cut first and then adjust the table as

necessary for your requirements.

Note.

When bevel cutting, the drop foot (8) can be tilted so it’s

parallel to the table and rests flat against the workpiece. To tilt

the drop foot, loosen the Allen screw at the front of the drop foot

assembly and then tilt the foot so that it’s parallel to the table,

re-tighten the Allen screw to secure the drop foot in place.

Aligning the degree scale pointer

1. Loosen the table lock knob (17) and rotate the table

adjustment knob (18) to position the table at a right

angle to the blade.

2. Place a small square on the table next to the blade

to check if the table is at a 90º angle to the blade. If

adjustment is needed, change the bevel angle until the