Global Machinery Company LS1620 User Manual

Page 8

8

Mounting the saw to a workbench

It is recommended that the scroll saw is secured to a

work bench to gain maximum stability and prevent noise

and vibration.

1. Using the base of the scroll saw as a template mark the

holes on the workbench through the holes in the casting.

2. Drill the holes through the workbench using an 8mm

drill bit.

3. Bolt the saw to the workbench using bolts, washers

and nuts.

Note.

The fasteners are not

supplied with the machine.

Note.

A soft foam pad or carpet

(not supplied) can be placed

between the scroll saw and the

work bench to further reduce

noise and vibration.

Blades

The scroll saw accepts 127mm pin type and flat blades.

A flat blade adapter is not required.

Selecting the correct blade

1. The scroll saw accepts a wide variety of blade widths

and thicknesses for cutting wood and other wood

based materials.

2. The blade width, thickness, and number of teeth per inch

will be determined by the material and size of the radius

being cut.

3. Select a blade that allows at least three (3) teeth to be

in contact with the workpiece at all times.

4. Very fine, narrow blades should be used for curve cutting

in thin wood (6mm or less).

5. To cut thicker wood, use wider blades with fewer teeth

per inch.

6. When cutting wood thicker than 25mm, guide the

workpiece into the blade slowly and take care not

to bend or twist the blade whilst cutting.

7. Most blade packages state the size or thickness of

wood which that blade is intended to cut, and the radius

(size of curve) which can be cut with that blade.

8. Wider blades cannot cut curves as tight or small as

thinner blades.

9. This saw uses 127mm long pin type and flat blades.

10. Blades wear faster when:

a. Cutting plywood which is very abrasive

b. Cutting wood that is thicker than 19mm

c. Cutting hardwood

d. Side pressure is placed

on the blade

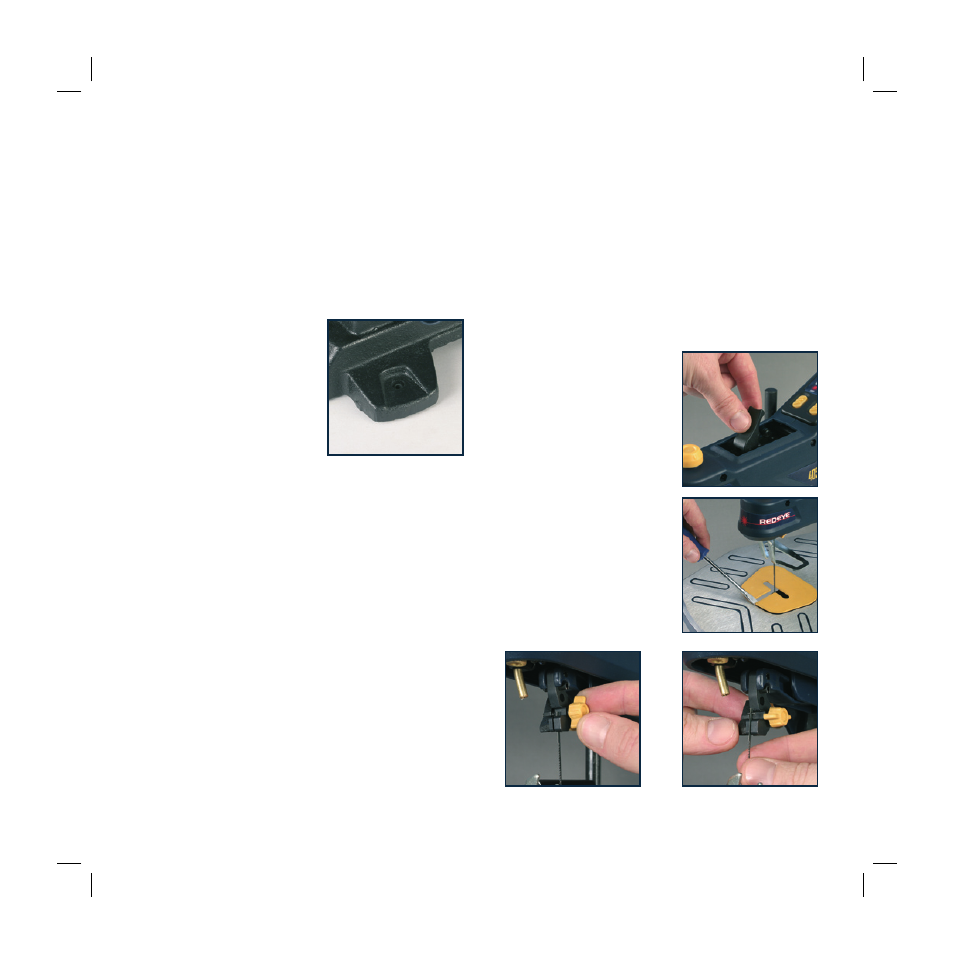

Removing blades

CAUTION.

Always ensure that the

saw is switched off and unplugged

from the mains supply before

removing or installing a blade.

1. Lift up the blade tension

lever (12) to reduce the

blade tension.

2. Remove the table insert (11)

by raising it with a screwdriver.

3. Loosen the upper and lower

blade adapter knobs (14).

4. Remove blade from the upper

and lower blade adapters (13).