Global Machinery Company LS1620 User Manual

Page 12

12

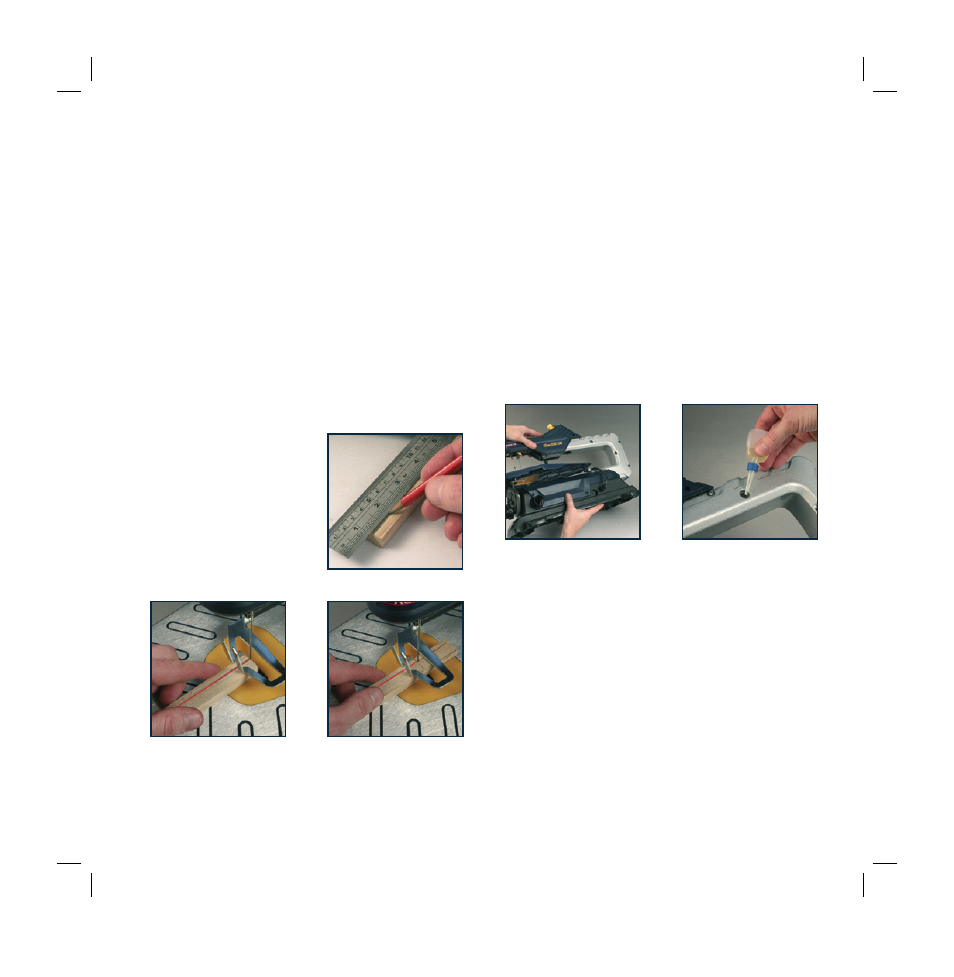

Using the REDEYE

®

laser line generator

WARNINGS.

Do not stare directly at the laser beam.

Never aim the beam at any person or an object other than

the work piece.

Do not deliberately aim the beam at personnel and ensure

that it is not directed towards the eye of a person for longer

than 0.25s.

Always ensure the laser beam is aimed at a sturdy work

piece without reflective surfaces, i.e. wood or rough coated

surfaces are acceptable. Bright shiny reflective sheet steel

or the like is not suitable for laser use as the reflective

surface could direct the beam back at the operator.

1. Mark the line of cut on the workpiece.

2. To start the saw lift up the

on/off switch (1).

3. Adjust the speed to suit the

workpiece being cut.

4. Switch on the laser beam

using the laser light on/off

switch (2).

5. Line up the laser line with the

line on the workpiece

6. To begin the cut guide the wood

into the moving saw blade.

7. Switch off the laser beam on completion of the cut.

8. Once finished push the on/off switch down to turn off the

saw and unplug the tool from the power point to prevent

unauthorised use.

Maintenance

WARNING.

Always ensure that the tool is switched off and

the plug is removed from the power point before making

and adjustments or maintenance procedures.

An occasional coat of paste wax on the work table will allow

the wood being cut to glide smoothly across the work surface.

Oiling the arm bearings

The saws arm bearings should be lubricated after every

50 hours of use. Ensure plug is removed from the mains

power supply.

1. Turn the saw on its side.

2. Squirt a generous amount of SAE 20 oil around the shaft

end and bronze bearings.

3. Let the oil soak in overnight in this position.

4. Next day repeat the above procedure for the opposite

side of the saw.

Cleaning

1. Keep the tool’s air vents unclogged and clean at all times.

2. Remove dust and dirt regularly. Cleaning is best done

with a brush or a rag.

3. Re-lubricate all moving parts at regular intervals.

4. Never use caustic agents to clean plastic parts.

CAUTION.

Do not use cleaning agents to clean the plastic

parts of the tool. A mild detergent on a damp cloth is

recommended. Water must never come into contact with

the saw.