Global Machinery Company LS1620 User Manual

Page 11

11

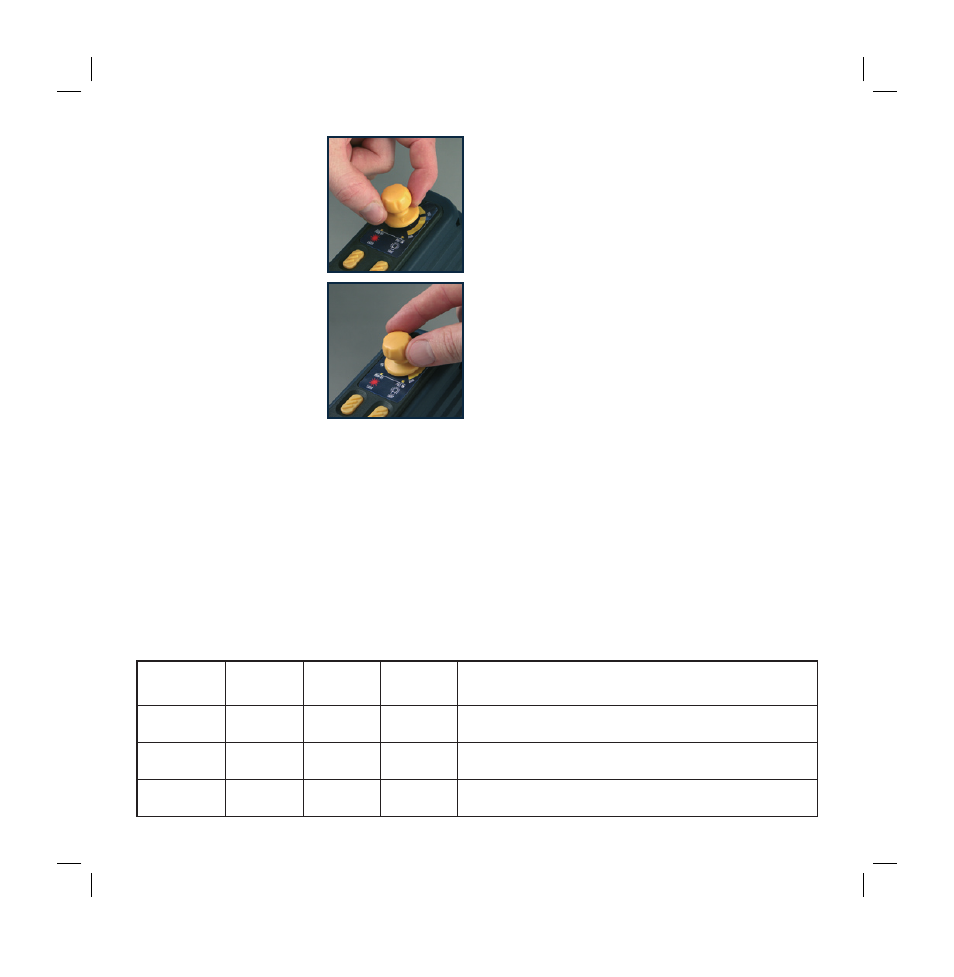

Adjusting the speed

The speed can be adjusted to

suit the workpiece being cut. The

variable speed dial (1) is located at

the top of the saw for convenient

adjustment of the speed.

1. Turn the saw on by lifting the

on/off switch (1).

2. Turn the dial in a clockwise

direction for a faster speed

and in an anti-clockwise

direction to reduce the speed.

3. Determine the optimum speed

by making a trial cut in a scrap

piece of material.

Note.

Using the correct speed for

the job increases the life of the saw blade.

Selecting the correct speed

The below table shows the most appropriate blade and

speed to be used for different materials and applications.

Scroll saw operation

1. Ensure that the table insert is in place and flush with

the table.

2. To start the saw lift up the on/off switch (1).

3. Adjust the speed to suit the workpiece being cut.

4. To begin the cut guide the wood into the moving saw

blade, the blade teeth cut only on the down stroke.

5. The saw will not cut wood by itself, you allow the saw to

cut wood by guiding the wood into the blade as it moves.

6. The drop foot (8) should always be lowered until it just

rests on top of the workpiece to prevent your workpiece

from lifting during operation but not so much that the

workpiece drags. To lower or raise the drop foot loosen

the drop foot locking knob (9) and position the drop foot

so it rests on top of the work piece. Retighten the drop

foot locking knob.

7. Ensure that you feed the wood into the blade slowly

because the teeth of the blade are very small and

they can only remove wood when they are on the

down stroke.

8. The blade will flex backwards when applying feed

pressure. Too much feed pressure will cause blade

breakage.

9. Best results are achieved when cutting wood less than

25mm thick.

10. When cutting wood thicker than 25mm, the user must

feed the wood into the blade very slowly, increase blade

tension and take extra care not to bend or twist the

blade while cutting in order to maximise blade life.

11. Teeth on scroll saw blades wear quickly and as a result

must be replaced frequently for best cutting results.

Scroll saw blades generally stay sharp for 30 minutes

to 2 hours of cutting.

12. Once finished push the on/off switch down to turn off the

saw and unplug the tool from the power point to prevent

unauthorised use.

Blade Teeth

per Inch

Width

Thickness Strokes

per Minute Material and Application

6 - 10

2.8mm

0.5mm

1200–1600 Hard and soft woods from 5mm to 50mm thick

plastics, paper, felt

10 - 15

2.8mm

0.5mm

600–1200

Wood, plastics, extremely thin cuts in materials

2.5mm to 13mm thick

15 - 18

2.4mm

0.3mm

400–600

Tight radius work in thin materials 2.5mm to 3mm thick.

Wood, veneer, fiber, plastic.