Setting spindle speed, Calculating spindle speed – Grizzly G0695 User Manual

Page 30

-28-

model g0695 (mfg. since 9/10)

Setting Spindle

Speed

to select the correct spindle speed (rpm) for your

milling operation, you will need to: 1) determine

the spindle speed needed for your workpiece, and

2) set the speed dial for the calculated speed.

this mill is designed to use most end mills, drill

bits, and face cutters that are 3" in diameter

or less. the milling table has a coolant system

trough with drain for an optional fluid system.

Calculating Spindle Speed

1. Use the table in figure 29 to determine the

cutting speed or surface feet per minute

(sFm) required for your workpiece material.

Cutting Speeds for High Speed Steel (HSS)

Cutting Tools

Workpiece material

Cutting speed (sFm)

aluminum & alloys

300

Brass & Bronze

150

Copper

100

Cast iron, soft

80

Cast iron, hard

50

mild steel

90

Cast steel

80

alloy steel, hard

40

tool steel

50

stainless steel

60

titanium

50

plastics

300-800

Wood

300-500

Note: For carbide cutting tools, double the cutting

speed. These values are a guideline only. Refer to

the MACHINERY'S HANDBOOK for more detailed

information.

figure 29. Cutting speed table for hss cutting

tools.

3. Use the following formula to calculate the

required spindle speed (rpm) for your opera-

tion:

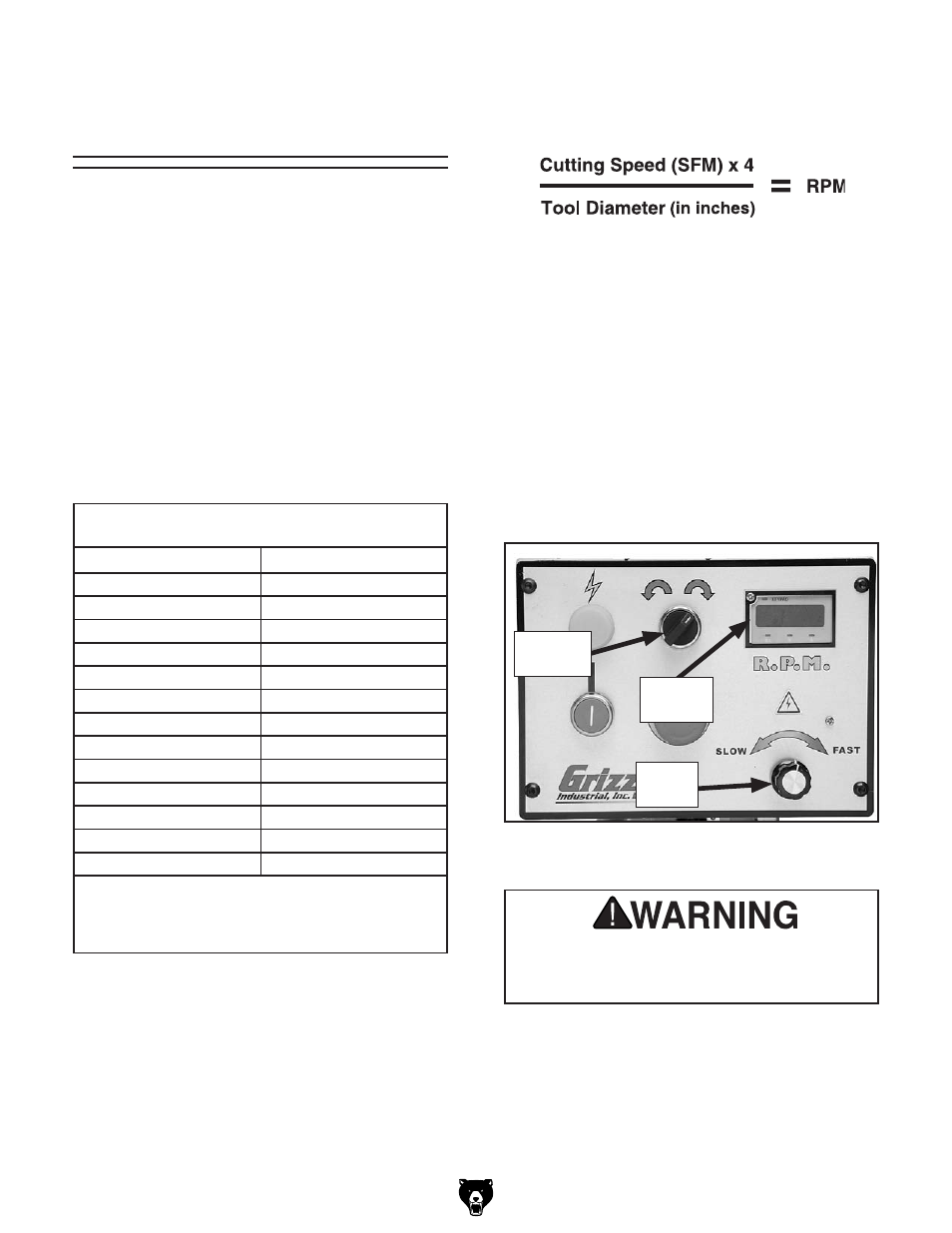

Setting Spindle Speed

1. rotate the speed dial all the way to the left,

setting the startup spindle speed close to

zero.

Note: This precaution avoids unexpected

high speed startup of the spindle.

2. Use the direction switch to select the direc-

tion of spindle rotation, turn the spindle

ON,

then rotate the speed dial until the calculated

spindle speed is displayed at the digital read-

out on the control panel (see

figure 30).

figure 30. spindle direction switch, speed dial,

and digital readout.

digital

readout

direction

switch

speed

dial

2. measure the diameter of your cutting tool in

decimal inches.

failure to follow spindle speed and feed rate

guidelines may threaten operator safety

from ejected parts or ejected tools.

Remember: Milling with the quill fully extended

can cause tool chatter. For maximum spindle

rigidity, keep the spindle retracted into the head-

stock as far as possible with the quill lock lever

locked and the downfeed selector tightened.