GE E4LE User Manual

Page 30

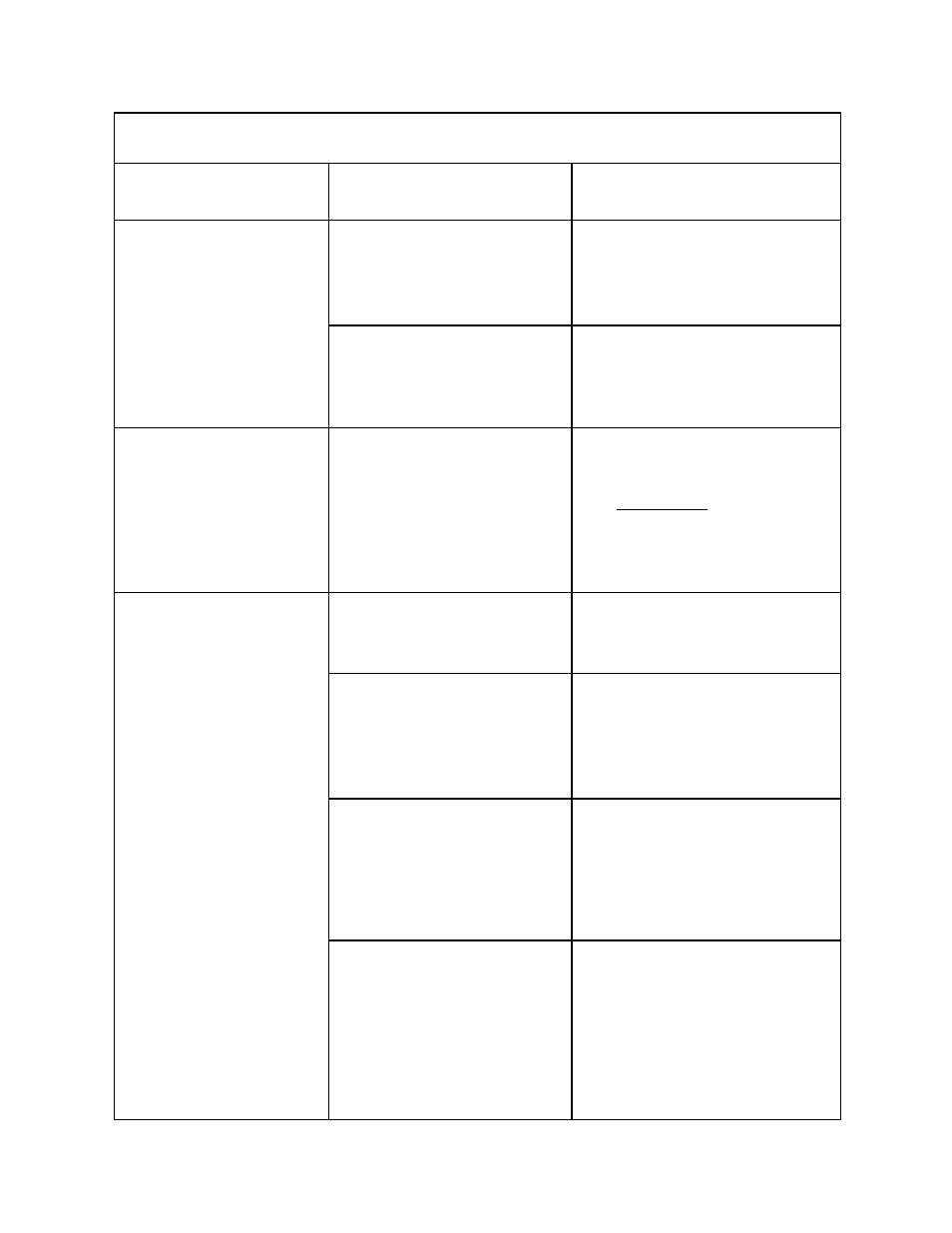

25

POSSIBLE CAUSE

Telescoped membrane element

covering membrane element

housing outlet port

Severely fouled or dirty

membrane elements

Inlet solenoid valve not closing

or seating properly

Dirty or fouled membrane

elements

O-ring seal broken or damaged

Change in incoming water

quality

Inaccurate conductivity monitor

or fouled probe

PROBLEM

Excessive pressure drop

[over 50 psig (3.0 barg)]

(high primary pressure -

low final pressure)

(continued)

Water flowing when

machine is turned OFF

Declining rejection

(high permeate

conductivity)

SOLUTION

Flush and clean the membrane

elements

Flush the machine then clean it with

detergent.

Clean or replace the valve. Clean

the membrane elements with deter-

gent immediately. Water must not

pass through the inlet when the

machine is OFF.

Flush and clean the membrane

elements

Replace the O-ring, check the seal-

ing surfaces on the O-ring groove,

interconnectors and end caps.

Replace the damaged parts.

Open the concentrate valve and

flush. Test the water for pH, hard-

ness, TDS and iron content. A water

analysis should be sent to GE

Infrastructure for review.

Calibrate the monitor with a DS

standard solution or check the

readings with another conductivity

meter. Replace or clean the probe.

Check the connections between the

probe and monitor.

T R O U B L E S H O O T I N G G U I D E