Set the burner air pressure differential, Set the maximum firing rate, Maximum firing rate adjustment – Greenheck Fan VSU Make-Up Air Unit with Direct-Fired Gas Heater 470654 User Manual

Page 16: Burner and baffles, Direct gas nameplate, Combined regulator valve, Measuring the pressure drop

16

Model VSU Make-Up Air

®

IMPORTANT

Proper air velocity over the burner is critical on direct-

fired gas units. If the air velocity is not within the unit

specifications, the unit will not operate efficiently,

may have sporadic shutdowns, and may produce

excessive carbon monoxide (CO) or other gases.

Set the Burner Air Pressure Differential

With the fan running and discharging 70ºF (21ºC) air,

connect a U-Tube manometer to the outer sensing

probes (see below) and measure the static pressure

across the burner.

Adjustable

Baffle

Airflow

Burner

Adjustable

Baffle

Airflow

Burner and Baffles

NOTE

The pressure drop was set at the factory and may not

need adjustment.

NOTE

When required pressure is obtained, be sure to

reconnect the outer sensing probes.

IMPORTANT

This process may need to be repeated until the proper

pressure is achieved. This adjustment will change the

air quantity delivered by the unit and therefore the air

quantity delivered should be rechecked. Refer to the

Blower Start-Up section.

NOTE

To increase the static pressure decrease the opening.

To decrease the static pressure increase the opening.

Set the Maximum Firing Rate

Monitor the unit’s actual temperature rise by placing

a thermocouple in the unit’s inlet and a second in the

discharge, three duct diameters downstream of the burner.

Send the unit to maximum fire by disconnecting and

isolating the wire connected to Terminal 3 on the Maxitrol

14 or the Maxitrol 44. See images on page 18.

While monitoring the units temperature rise, set the

maximum firing rate by adjusting the regulator until the

designed temperature rise is achieved. After setting the

maximum firing rate, reconnect the wire to the amplifier.

NOTE

Do not set the burner maximum firing rate based on gas

pressure. It should be set based on the unit’s designed

temperature rise shown on the direct gas label.

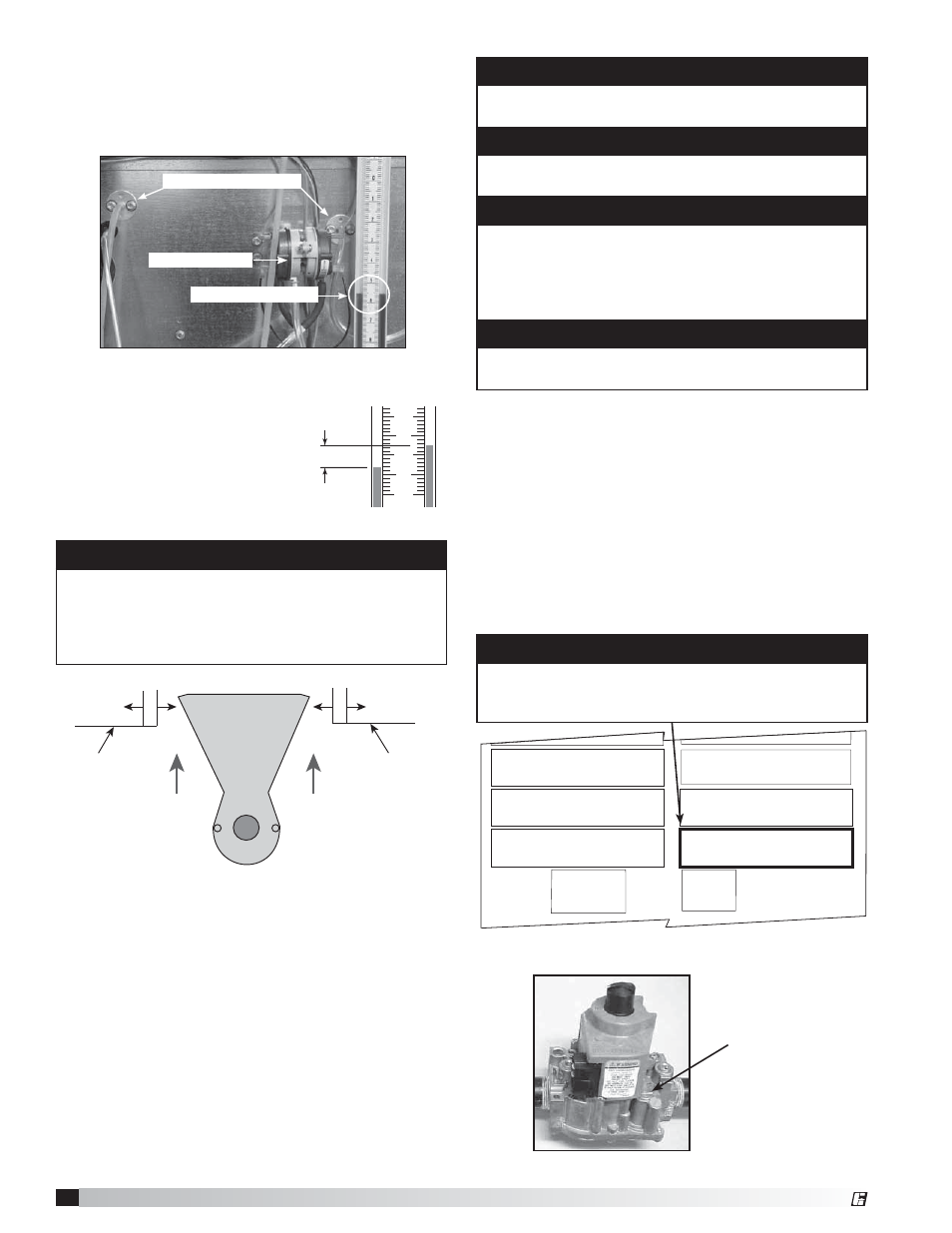

Direct Gas Nameplate

“ WC

“ WC

F

PSI

“ WC

MIN GAS

PRESSURE

PRESSION DE GAZ

MIN BURNER

PRESSURE DROP

PERTE MIN DE PRESSION

DANS LE BRULEUR

TYPE OF GAS

NATURE DU GAZ

MAX BURNER

PRESSURE DROP

PERTE MAX DE PRESSION

DANS LE BRULEUR

MAX GAS

PRESSURE

PRESSION DE GAZ

MAX

DESIGN ΔT

ΔT NORMALE

EQUIPPED FOR

CONCU POUR

SCFM

“ WC

EXTERNAL STATIC PRESSURE

PRESSION STATIQUE EXTERIEURE

AGAINST

CONTE

Maximum firing

rate adjustment

Combined Regulator Valve

The proper static pressure should be

between 0.625 and 0.675 inches

wg (155.68 and 168.64 Pa). If

needed, evenly adjust the

baffles above and below the

burner, keeping the burner

centered in the opening until the

required pressure is obtained.

7

6

0.625 - 0.675 in. wc

Measuring the Pressure Drop

Outer Sensing Probes

Pressure Switch

U-Tube Manometer