GE DPGT750EC/GC User Manual

Page 41

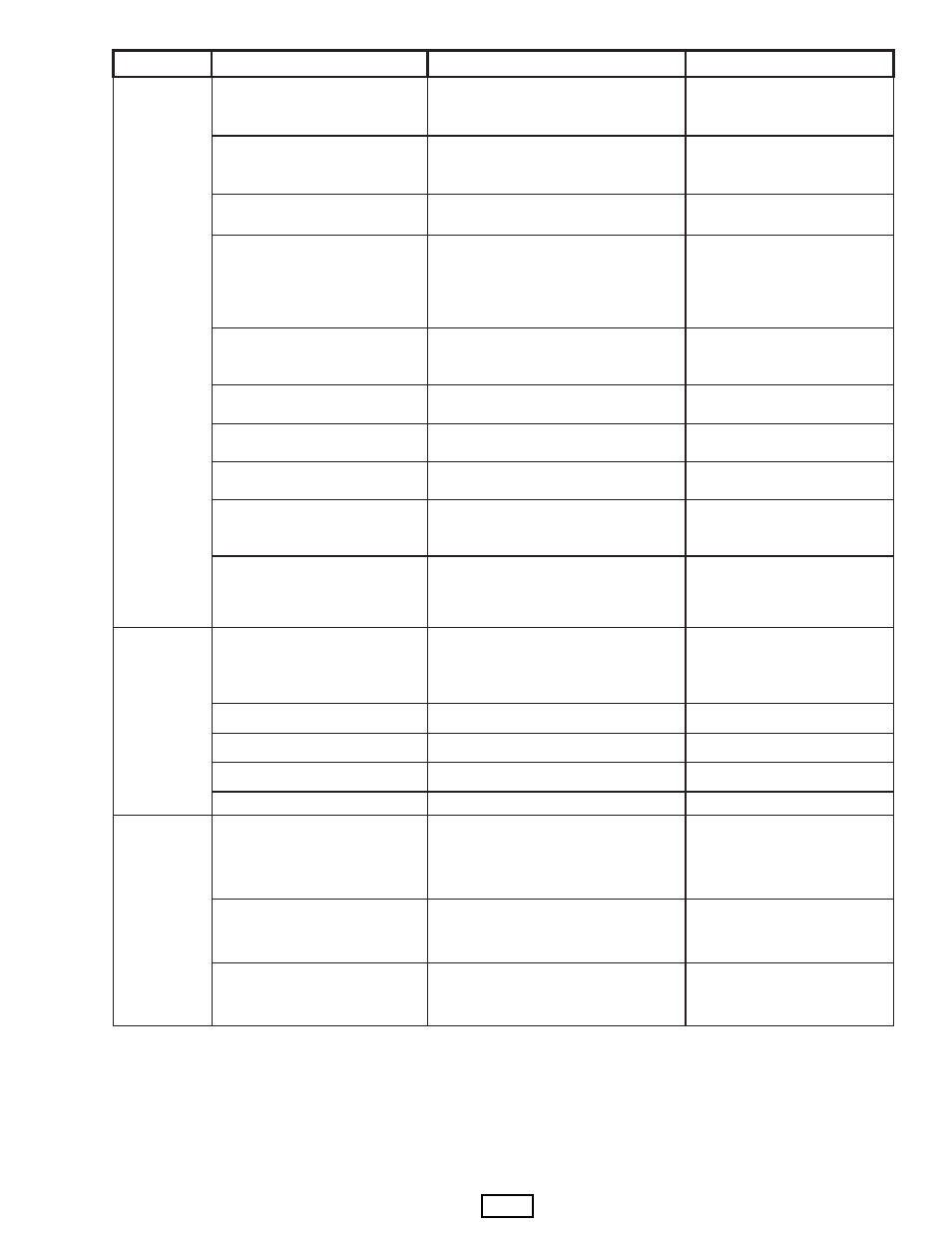

PROBLEM

POTENTIAL CAUSE

DIAGNOSTIC PROCEDURE

ACTION

Heater error (Gas)

Check service mode for heater error.

If heater error is displayed,

proceed with diagnostic

procedures in the order below.

Low line voltage

Line voltage must be greater than 96V.

Software will not allow gas valves to

operate below 96VAC.

Inform owner of low line voltage.

No gas supply

Check gas valve and pressure.

Open valve. Inform consumer of

no gas pressure.

Ignitor failure

With front panel removed and door switch

reconnected, start a cycle and check for

ignitor glow. If ignitor doesn’t glow, check

ignitor resistance at the ignitor connector

(100 - 500 Ohms).

Replace ignitor

Flame detector failure.

With front panel removed and door switch

reconnected, start a cycle and check that

ignitor turns on/off.

Replace flame detector.

ON/OFF gas valve failure

Check resistance of ON - OFF valves

(1800 - 1900) ohms.

Replace valve assembly.

Linear Gas Valve Failure

Check resistance of linear valve (60 - 70)

ohms.

Replace valve assembly.

Thermostat failed open

Check continuity of Outlet and Hi-Limit

thermostats.

Replace appropriate thermostat.

Centrifugal switch failure

Check centrifugal switch continuity in open

and closed state, according to the

terminals shown on the mini-manual.

Replace drum motor.

Thermistor failure

Check room-temperature resistance of

thermistor. Outlet thermistor resistance

range is 10K+-3% @ 25C, inlet thermistor

range is 2.27K +- 5%.

Replace thermistor.

Won’t Start -

controls dead

Low L1 voltage

Check L1 voltage at outlet.

If zero (0), check circuit breaker

or fuses. If below 30V, the

controls will not operate. Tell

consumer to call electrician.

Tripped safety thermostat

Check safety thermostat continuity

Reset or replace if necessary.

Defective main control board

Check service mode

Replace control board

Defective inverter board

Check service mode

Replace inverter board

Broken Belt

Remove front panel. Check belt.

Replace belt.

Won’t start -

controls OK

Open winding on drum motor

Check resistance of start and run

windings. Should be approximately

7.2 Ohms for start winding and 3.1 Ohms

for run winding.

Replace drum motor

Door switch failure (door open)

Check if switch is connected. Check if

lamp works. Check if dryer runs with door

open.

Connect or replace door switch.

Centrifugal switch failure

Check centrifugal switch continuity in open

and closed state, according to the

terminals shown on the mini-manual.

Replace drum motor.

Long Dry Time

Dryer Not

Heating

continued