Global Machinery Company WTS550 User Manual

Page 12

12

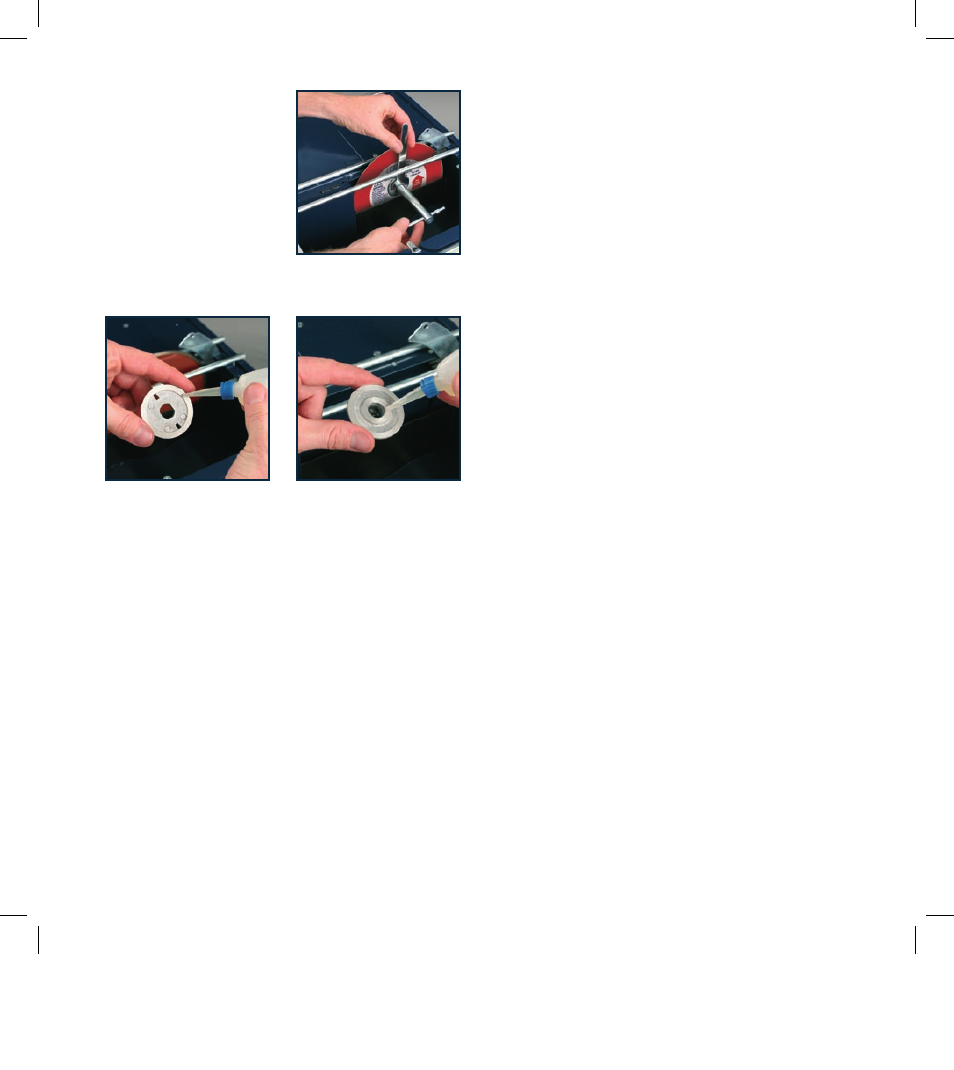

4. Take the 2 spanners and

use the flat spanner to

locate into the holes in the

flange and keep the blade

still, and use the socket

spanner over the nut and

turn anti clockwise.

5. Remove the nut, outer blade

flange and blade.

6. Wipe a drop of oil onto the inner blade flange and the

outer blade flange where they contact the blade.

7. Fit the new blade onto the spindle taking care that the

inner blade flange sits behind the blade.

CAUTION.

Always install the blade with the arrow printed on

the side of the blade pointing down. The direction of blade

rotation is also marked on the blade guard and blade cover.

8. Replace the outer blade flange followed by the blade nut.

9. Use the blade spanner to securely tighten the blade bolt.

(Tighten in a clockwise direction).

10. Replace the blade cover and secure it with the blade

cover locking knobs.

CAUTION.

Before using the saw after replacing the blade,

check that all the safety devices are fitted correctly including

the blade guard and that they are all in good working order.

Run the saw without loading it to ensure the blade runs true

and there are no extraneous noises.

Cleaning

1. Keep the tool’s air vents unclogged and clean at all times.

2. Remove dust and dirt regularly. Cleaning is best done

with a soft brush or a rag.

3. Re-lubricate all moving parts at regular intervals.

4. Never use caustic agents to clean plastic parts.

CAUTION.

Do not use cleaning agents to clean the

plastic parts of the saw. A mild detergent on a damp

cloth is recommended.

General inspection

Regularly check that all the fixing screws are tight. They

may vibrate loose over time.

Repairs

Only an authorised service centre should replace the

cordset. If the cordset is damaged or worn, have it repaired

or replaced by an authorised service centre.

Power cord and RCD maintenance

IMPORTANT.

Ensure the RCD is tested upon every use.

It is essential that the safety switch is tested to ensure it is

functioning correctly. We strongly recommend that a test of

the RCD is conducted without fail before each use. Refer to

Testing your safety switch.

If the power cord or RCD needs replacing, the task must

be carried out by the manufacturer, the manufacturer’s

agent, or a qualified electrical repairer in order to avoid a

safety hazard.