Warning – John Wood Power Vent 0.67 EF User Manual

Page 29

Anode Rod Replacement

To replace the anode:

1.

Turn off gas supply to the water heater.

2.

Shut off the water supply and open a nearby hot-water

faucet to depressurize the water tank.

3.

Drain approximately 20 litres (5 US gallons) of water

from tank (Refer to "Draining and Flushing" for proper

procedures.) Close drain valve.

4.

Remove old anode rod.

5.

Use Teflon® tape or approved pipe sealant on threads

and install new anode rod.

6.

Turn on water supply and open nearby hot-water faucet

to purge air from water system.

7.

Restart the water heater as directed under "Operating

Your Water Heater." See the "Parts Reference

Illustration" for anode rod location.

Routine Preventative Maintenance

Important: If you lack the necessary skills required to prop-

erly perform this visual inspection, you should not proceed,

but get help from a qualified service technician.

At least annually, a visual inspection should be made of the

venting and air supply system, piping systems and main

burner. Check the water heater for the following:

• Build up of soot and carbon on the main burner. Check

for a soft blue flame.

• Leaking or damaged water and gas piping.

• Presence of flammable or corrosive materials in the

installation area.

• Presence of combustible materials near the water

heater.

• Verify proper operation after servicing this water heater.

Gas Control

There are no user serviceable parts in this control. The con-

trol is supplied with tamper resistant screws. DO NOT

attempt to repair or adjust the control. If you experience

problems, discontinue use and replace the control immedi-

ately. Continuing to use a damaged control could result in

fire and/or explosion.

If you wish to verify that the water heater is operating prop-

erly:

1.

Make sure there is power to the water heater.

2.

Make sure that the gas is turned on to the water heater.

3.

Initiate a call for heat by either drawing hot water from a

nearby faucet or raising the temperature setting (see

section “Temperature Regulation”).

4.

Note any error codes that appear and proceed to the

“Troubleshooting” section.

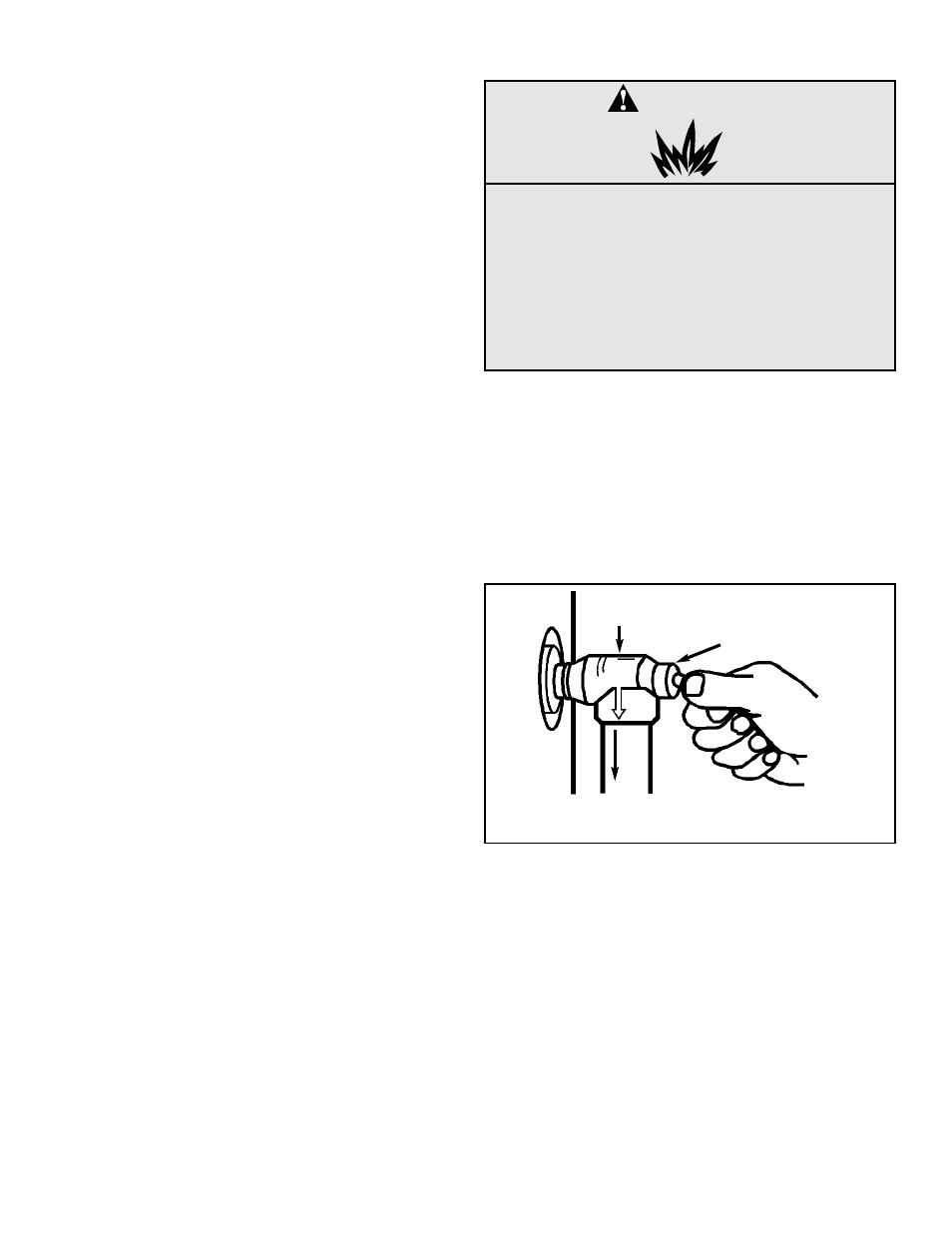

Temperature and Pressure Relief Valve

Manually operate the temperature and pressure relief valve

at least once a year to make sure it is working properly (see

Figure 27). To prevent water damage, the valve must be

properly connected to a discharge line that terminates at an

adequate drain. Standing clear of the outlet (discharged

water may be hot), slowly lift and release the lever handle

on the temperature and pressure relief valve to allow the

valve to operate freely and return to its closed position. If the

valve fails to completely reset and continues to release

water, immediately shut off the manual gas valve and the

cold-water inlet valve and call a qualified service technician.

– 29 –

WARNING

Explosion Hazard

• If the temperature and pressure relief

valve is dripping or leaking, have a

licensed plumber repair it.

• Do not plug valve.

• Do not remove valve.

• Failure to follow these instructions can

result in death or an explosion.

Temperature and Pressure

Relief Valve

Manual Relief Valve

Discharge line to drain

Figure 27 T&P Valve Test