Water supply – John Wood Power Vent 0.67 EF User Manual

Page 15

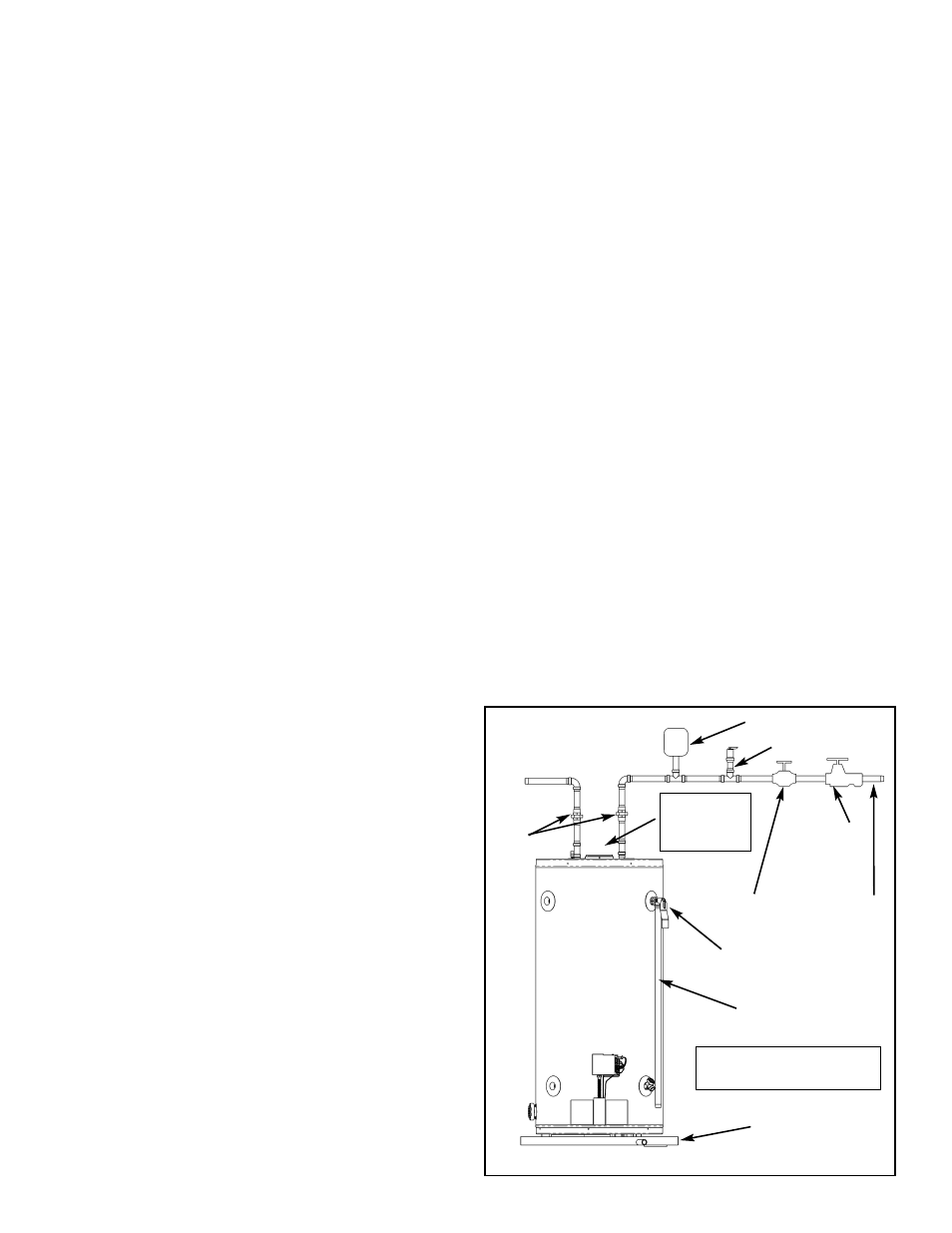

Water Supply

Piping Installation

Piping, fittings, and valves should be installed according to

the installation drawing (Figure 16). A pressure-reducing

valve and/or an expansion tank may be required for instal-

lations where the water pressure is high. The pressure-

reducing valve should be located on the supply to the entire

house in order to maintain equal hot and cold water pres-

sure.

Important:

• Do not apply heat to the water fittings on the heater as

they may contain nonmetallic parts. If solder connec-

tions are used, solder the pipe to an adapter before

attaching the adapter to the hot and cold water fittings.

• Some models may contain energy saving heat traps to

prevent the circulation of hot water within the pipes. Do

not remove the inserts within the heat traps.

• Always use a proper grade of joint compound and be

certain that all fittings are drawn up tight.

1.

Install the water piping and fittings as shown in Figure

16. Connect the cold water supply to the fitting (3/4"

NPT) marked "COLD" (or "C"). Connect the hot water

supply to the fitting (3/4" NPT) marked "HOT" (or "H").

2.

The installation of unions in both the hot and cold water

supply lines is recommended.

3.

The manufacturer of this water heater recommends

installing a tempering valve in the domestic hot-water

line as shown in Figure 17. These valves reduce the

point-of-use water temperature by mixing cold and hot

water. Contact a licensed plumber or the local plumbing

authority.

4.

If installing the water heater in a closed water system,

install an expansion tank in the cold water line as spec-

ified under "Closed System/Thermal Expansion".

5.

Install a shut-off valve in the cold-water inlet line. It

should be located close to the water heater and be eas-

ily accessible. The owner/operator must be shown the

location of this valve and be given instructions on how

to use it to shut off the water to the heater.

Filling the Water Heater

Do not insert the power cord into the electrical receptacle

until all the following steps have been completed.

1.

Make sure the drain valve is closed.

2.

Open all hot-water faucets served by the system to

allow air to escape from the tank.

3.

Open the cold-water inlet valve.

Note: When filling, avoid water leakage. Do not allow the

insulation of the water heater to get wet as water can reduce

the effectiveness of the insulation.

4.

When an uninterrupted stream of water, without appar-

ent air bubbles, flows from the open hot-water faucets,

the tank is full.

5.

Close the hot-water faucets and check the system for

leaks. Repair as required and retest.

Please note the following:

The system should be installed only with piping that is suit-

able for potable (drinkable) water such as copper, CPVC,

PEX or polybutylene. DO NOT use PVC water piping.

DO NOT use any pumps, valves, or fittings that are not

compatible with potable water.

DO NOT use valves that may cause excessive restriction to

water flow. Use full flow ball or gate valves only.

DO NOT use any lead based solder in potable water lines.

Use appropriate tin-antimony or other equivalent material.

DO NOT tamper with the gas control/thermostat, igniter,

flammable vapour sensor or temperature and pressure

relief valve. Tampering voids all warranties. Only qualified

service technicians should service these components.

DO NOT use with piping that has been treated with chro-

mates, boiler seal, or other chemicals.

DO NOT add any chemicals to the system piping which will

contaminate the potable water supply.

– 15 –

COLD WATER

INLET

COLD WATER

INLET VALVE

PRESSURE

REDUCING

VALVE

WITH

BYPASS

TEMPERATURE AND

PRESSURE RELIEF VALVE

HOT

WATER

OUTLET

UNION

DRAIN PAN CONNECT TO

PROPERLY OPERATING

FLOOR DRAIN.

DISCHARGE LINE 300mm

(12 in.) max (CANADA) OR

150mm (6 in.) max (U.S.)

ABOVE DRAIN

IN A CLOSED SYSTEM USE EITHER: 1.THERMAL EXPANSION TANK

OR

2.PRESSURE RELIEF VALVE.

Figure 16 Water Piping Installation

MASSACHUSETTS: INSTALL A

VACUUM RELIEF IN COLD WATER

LINE PER SECTION 19MGL 142

NOTE: BLOWER

ASSEMBLY NOT

SHOWN FOR

CLARITY.